Storage tank cleaning device and method

A technology for cleaning devices and storage tanks, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of acid-base solution, large water consumption, high safety hazards, and high cleaning costs, and achieves a reduction in The effect of water waste, lower use cost, and high cleaning safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

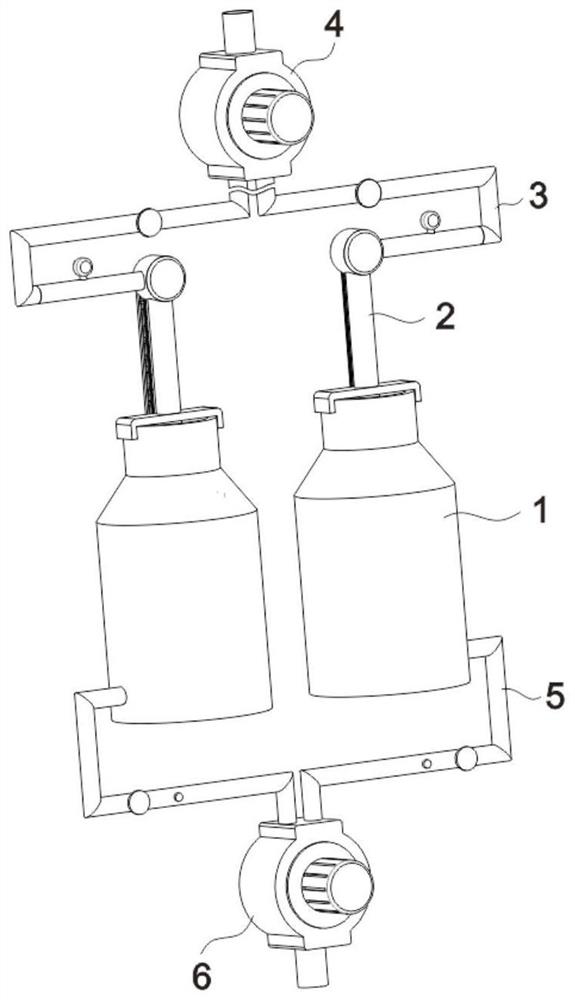

[0036] see figure 1 , a storage tank cleaning device, applied to multiple groups of storage tank main bodies 1 to perform synchronous cleaning operations, the cleaning device includes a rotary chemical cleaning component disposed on the top of the storage tank main body 1 for cleaning the interior of the storage tank main body 1 2;

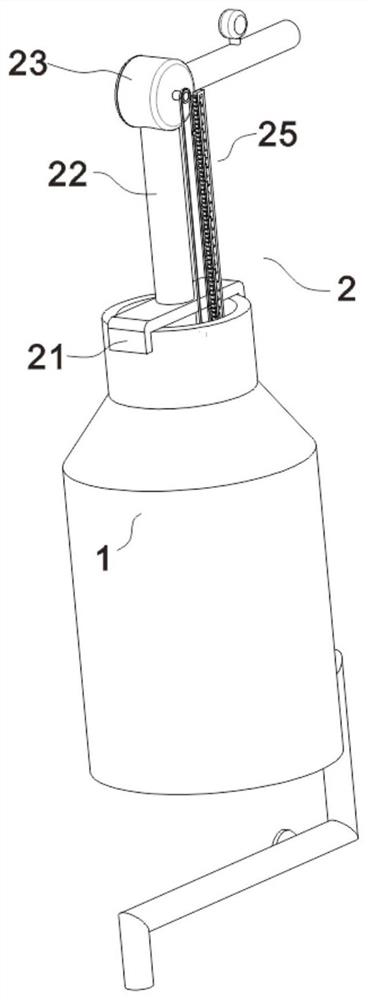

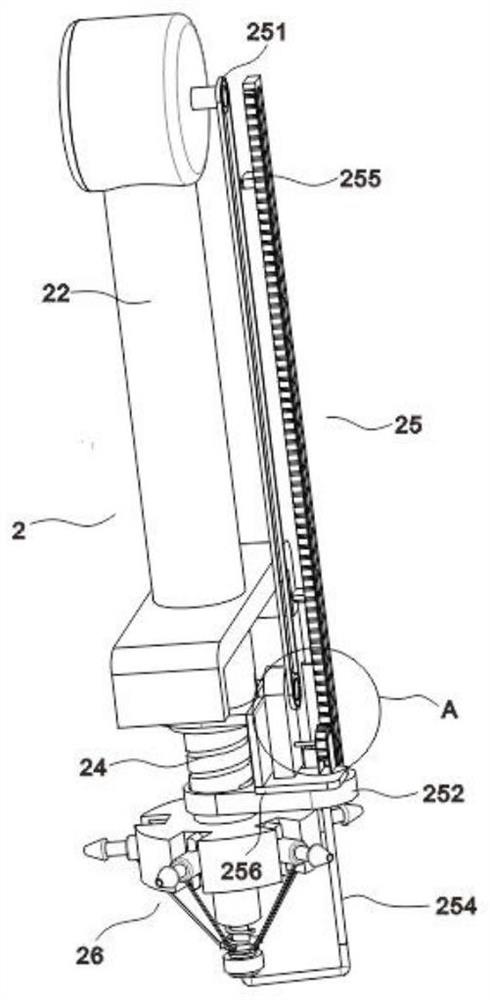

[0037] further, as figure 2 As shown, the rotary chemical cleaning assembly 2 includes a support frame 21 clamped on the top of the tank main body 1, a water inlet pipe 22 is fixed on the top of the support frame 21, and a threaded pipe 24 is inserted at the bottom of the water inlet pipe 22. The threaded pipe 24 The outer thread of the outer wall is connected with the inner thread of the inner wall of the water inlet pipe 22, so that the threaded pipe 24 can be rotated upwards or downwards. The top of the 22 is provided with a guide shell 23 that communicates with each other, and a follower impeller ((from the attached Figure 5 It can be see...

Embodiment 2

[0044] like Figure 6-7 As shown, the variable-direction nozzle 26 includes a hollow seat 261 disposed at the bottom of the threaded pipe 24 and communicated with it, and a plurality of groups of notches are provided in an annular array on the outer wall of the hollow seat 261, and the notches are rotated by a rotating shaft and a torsion spring. A nozzle main body 262 is provided. The outer wall of the nozzle main body 262 is provided with a branch pipe 263 that communicates with the inner cavity of the hollow seat 261 .

[0045] Among them, the function of the rotating shaft and the torsion spring enables one end of the nozzle body 262 to be turned downward, so that the cleaning range is wider when cleaning the bottom of the inner cavity of the tank body 1, and at the same time, the nozzle body 262 can be reset under the action of the torsion spring. to the horizontal state.

Embodiment 3

[0047] like Figure 6-7 As shown, a sealing cylinder 265 is provided at the center of the bottom of the hollow seat 261, a piston (not shown in the figure) is arranged in the inner cavity of the sealing cylinder 265, and the piston is fixedly sleeved on the top of the outer wall of the piston rod, and the top and bottom of the piston rod are both Hollow, wherein the bottom of the piston rod is communicated with one end of the connecting air pipe 254 through a rotary joint 267, a return spring is sleeved on the outer wall of the piston rod, a connecting ring 264 is sleeved at the bottom of the outer wall of the piston rod, and the outer wall of the connecting ring 264 is annularly arrayed A plurality of groups of connecting ropes 266 are provided, and the plurality of groups of connecting ropes 266 are in one-to-one correspondence with the nozzle main body 262, and the other end of the connecting rope 266 is connected with the bottom outer end of the nozzle main body 262;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com