Aluminum formwork for precast concrete pouring

A technology of prefabricated concrete and aluminum formwork, applied in the direction of manufacturing tools, machine tools suitable for grinding workpiece planes, grinding drive devices, etc., can solve problems such as difficulty in disassembly by workers, and achieve improved disassembly convenience, stable transmission, and low noise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

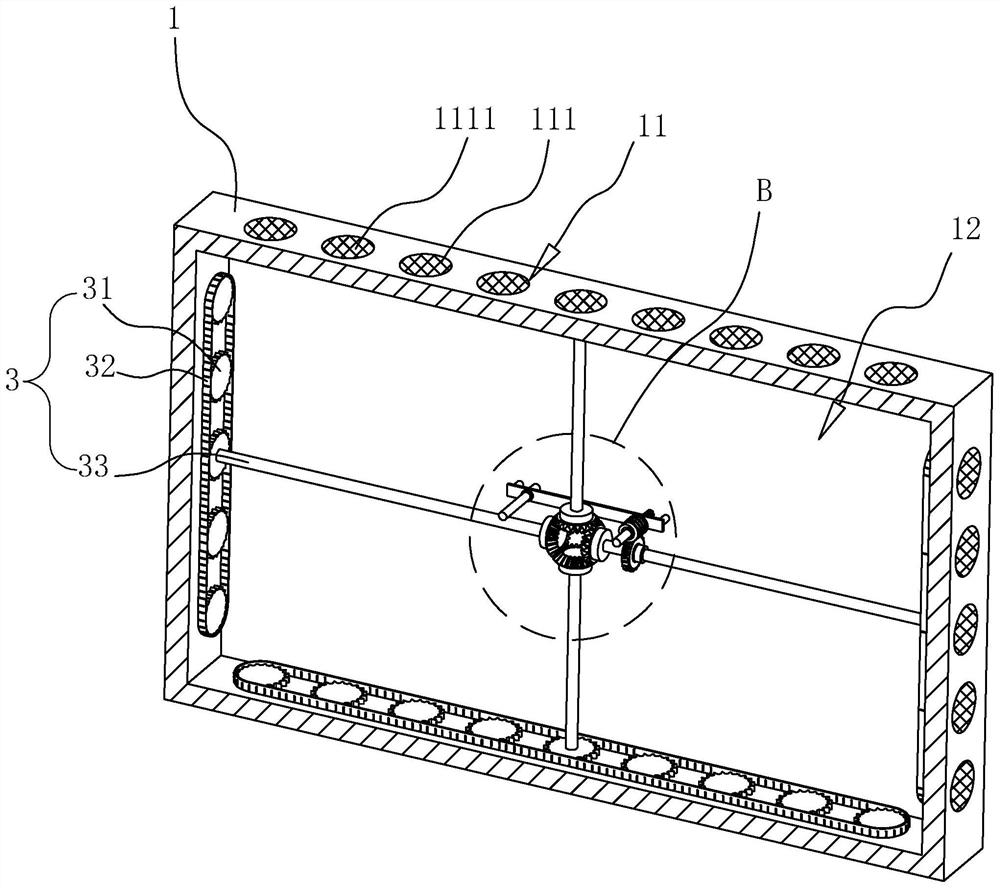

[0035] Attached to the following Figure 1-Figure 4 This application will be described in further detail.

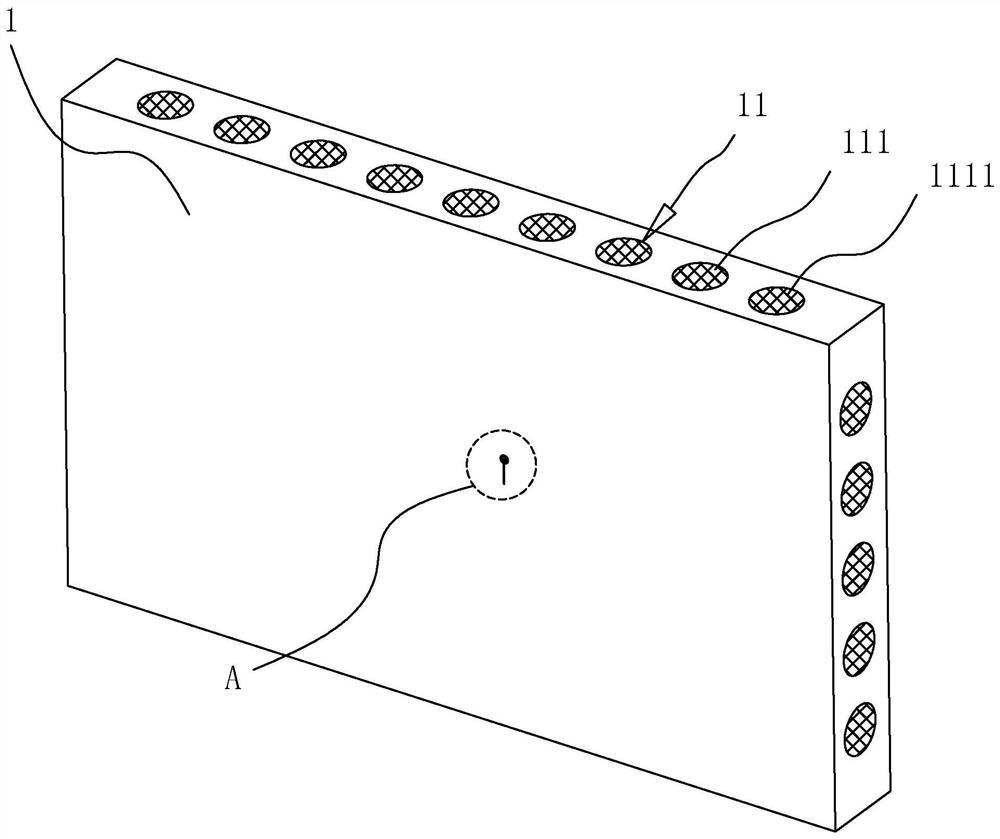

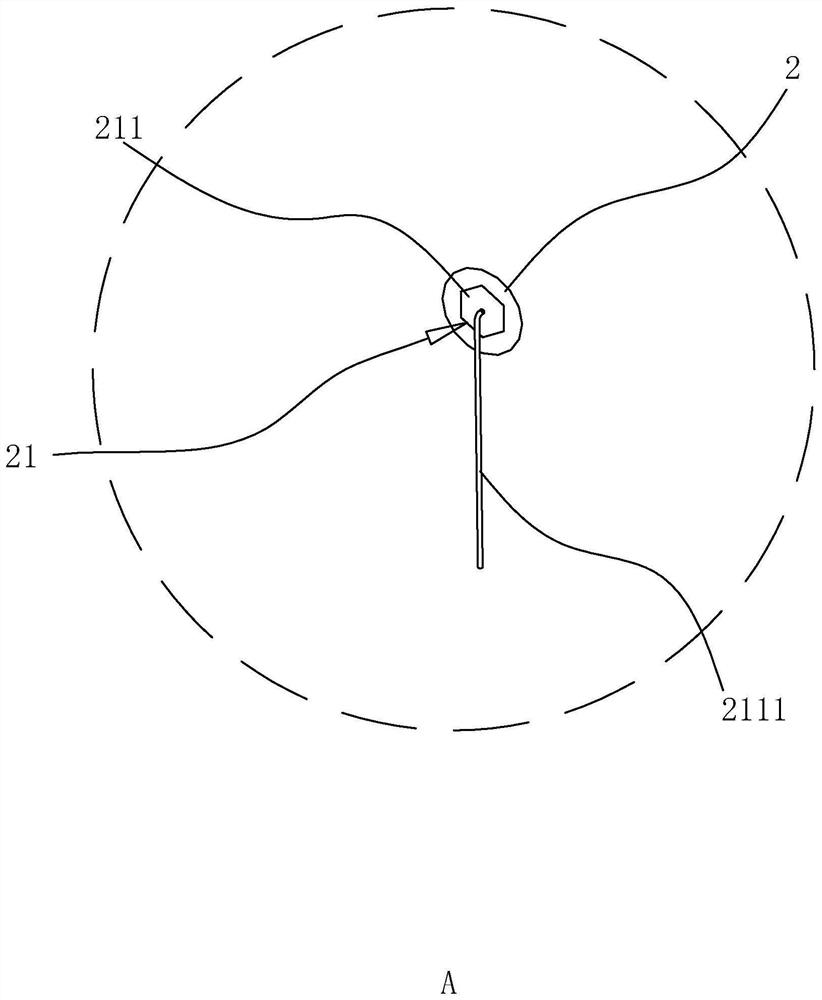

[0036] The embodiments of the present application disclose an aluminum formwork for precast concrete pouring. refer to figure 1 and figure 2 An aluminum formwork for precast concrete pouring comprises an aluminum formwork body 1, the aluminum formwork body 1 is arranged in a cuboid shape, the aluminum formwork body 1 is used for the pouring of concrete, and a concrete wall is formed after the concrete is poured, and four parts of the aluminum formwork body 1 are formed. Each wall surface and the back surface are in contact with the wall surface of the concrete wall. In the scheme, the concrete used by the aluminum formwork body 1 is the concrete used in small buildings. Such small buildings have low strength requirements for concrete, and the corresponding Concrete hardness is also lower.

[0037]Specifically, the four side walls of the aluminum formwork body 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com