Production process of fermented flowing-core pastries and production line of pastry production

A production process and fermentation process technology, applied in the direction of enzyme production/bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of unimproved, human injury, etc. Achieve good moisture absorption and moisturizing performance, reduce water loss, improve taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

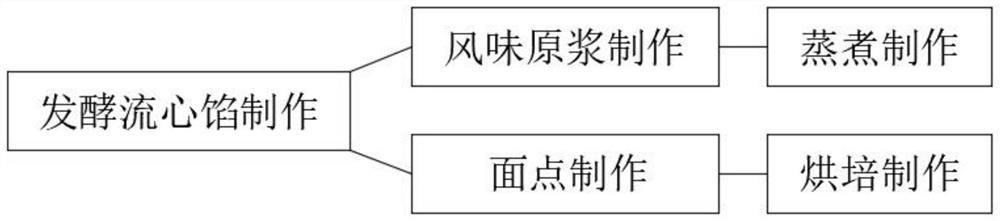

[0050] like figure 1 As shown in the figure, a production process of a fermented liquid pastry, the production steps are as follows:

[0051] A. Production of fermented heart filling

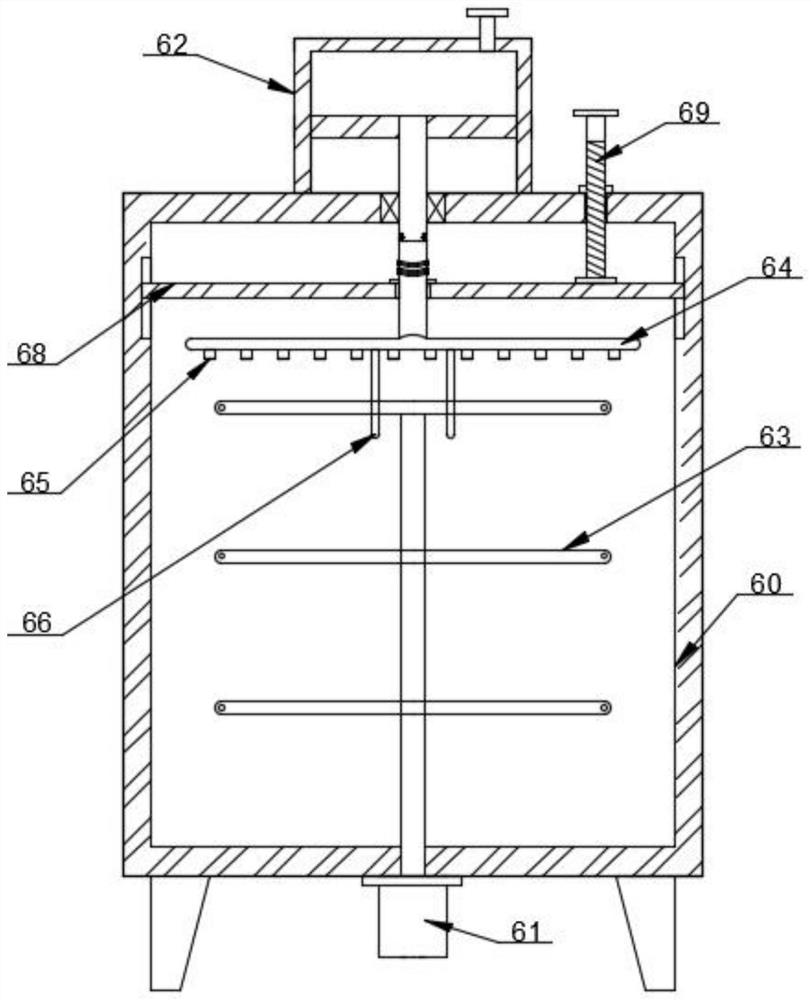

[0052] A1. The fermented liquid is sprayed into the soybean meal by self-made fermentation equipment and fully mixed, and the soybean meal is fermented at a constant temperature for 72 hours in the fermentation box, dried, cooled and pulverized to obtain the soybean meal rich in functional polypeptides;

[0053] A2. The ratio of soy flour, butter, sugar and salted egg yolk prepared from milk and A1 is 80:15:30:25:70. Use a heat-conducting container to pass through a 55° water bath and stir until it becomes viscous, then put it into the corresponding mold , and freeze for 2.5h to obtain liquid filling;

[0054] B. Flavor Puree Production

[0055] B1. is configured according to the ratio of H material and S material to 1.0:2.0, and filters to obtain raw pulp, and H material is one or more of wa...

Embodiment 2

[0062] like figure 1 As shown in the figure, a production process of a fermented liquid pastry, the production steps are as follows:

[0063] A. Production of fermented heart filling

[0064] A1. The fermented liquid is sprayed into the soybean meal by self-made fermentation equipment and fully mixed, and the soybean meal is fermented at a constant temperature for 72 hours in the fermentation box, dried, cooled and pulverized to obtain the soybean meal rich in functional polypeptides;

[0065] A2. The ratio of soy flour, butter, sugar and salted egg yolk prepared from milk and A1 is 78:12:26 ~ 32:22:67. Use a heat-conducting container to pass through a 60° water bath and stir until it becomes viscous. Put the corresponding , and freeze it for 2.5h to obtain a liquid filling;

[0066] B. Flavor Puree Production

[0067] B1. Configure according to the ratio of H material and S material to be 0.8:1.8, and filter to obtain raw pulp, and H material is one or more of water chestn...

Embodiment 3

[0074] like figure 1 As shown in the figure, a production process of a fermented liquid pastry, the production steps are as follows:

[0075] A. Production of fermented heart filling

[0076] A1. The fermented liquid is sprayed into the soybean meal by self-made fermentation equipment and fully mixed, and the soybean meal is fermented at a constant temperature for 72 hours in the fermentation box, dried, cooled and pulverized to obtain the soybean meal rich in functional polypeptides;

[0077] A2. The ratio of soy flour, butter, sugar and salted egg yolk prepared from milk and A1 is 85:18:32:29:74. Use a heat-conducting container to pass through a 65° water bath and stir until it becomes viscous, then put it into the corresponding mold , and freeze for 3h to obtain liquid filling;

[0078] B. Flavor Puree Production

[0079] B1. Configure according to the ratio of H material and S material to be 1.2:2.4, and filter to obtain raw pulp, and H material is one or more of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com