Handheld electric vacuum cleaner

A vacuum cleaner, hand-held technology, applied in the directions of vacuum cleaners, handles, cleaning methods, etc., can solve problems such as noise fan damage, and achieve the effect of suppressing damage, reducing noise, and efficiently collecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

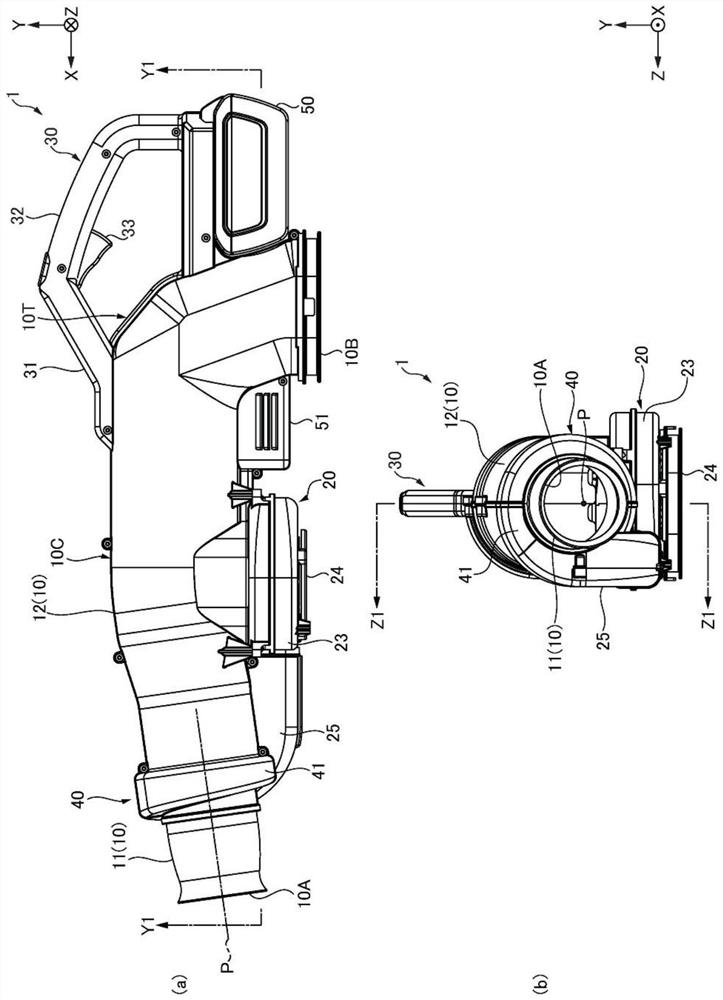

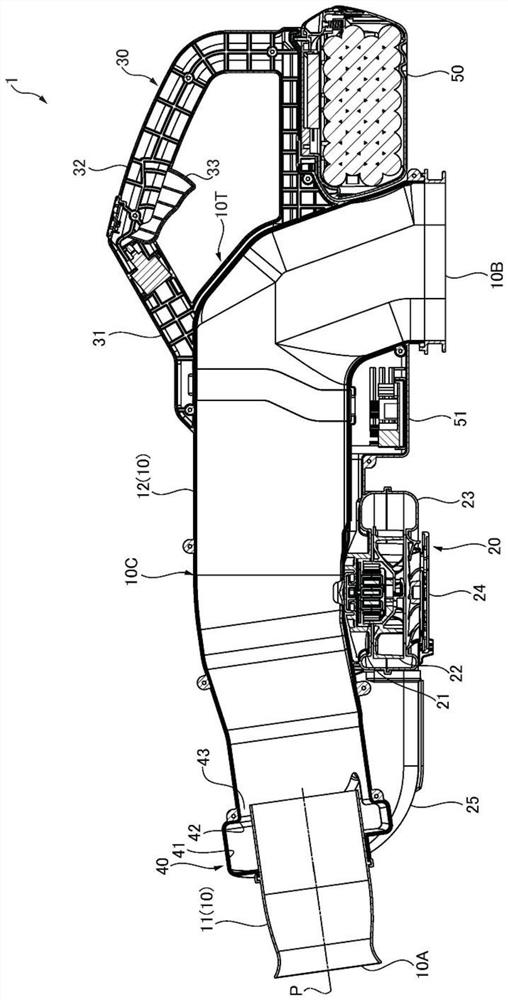

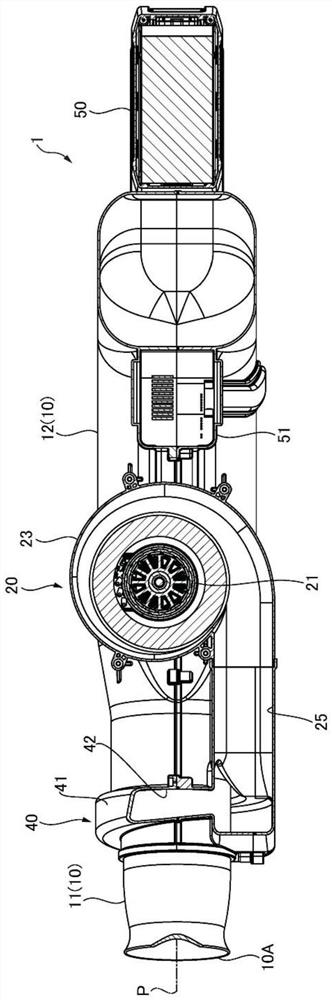

[0022] Embodiments of the present invention will be described below with reference to the accompanying drawings. In the following description, the same symbols in different drawings represent parts with the same functions, and therefore, repeated descriptions in the respective drawings will be omitted as appropriate.

[0023] like Figure 1 to Figure 3 As shown, a hand-held electric vacuum cleaner (hereinafter referred to as a vacuum cleaner) 1 is a hand-held working machine for suction operation, which includes a pipe tube 10 for suctioning dust or crop residues, a blower 20, a handle 30 , and the injector unit 40 .

[0024] The tube 10 has a suction port 10A at one end and a discharge port 10B at the other end, and discharges the aspirated material sucked into the tube 10 through the suction port 10A from the discharge port 10B. During the suction operation, a collection bag or the like, not shown, is attached to the discharge port 10B.

[0025] In the illustrated example...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap