Tool for inhibiting welding deformation of heat exchanger tube plate

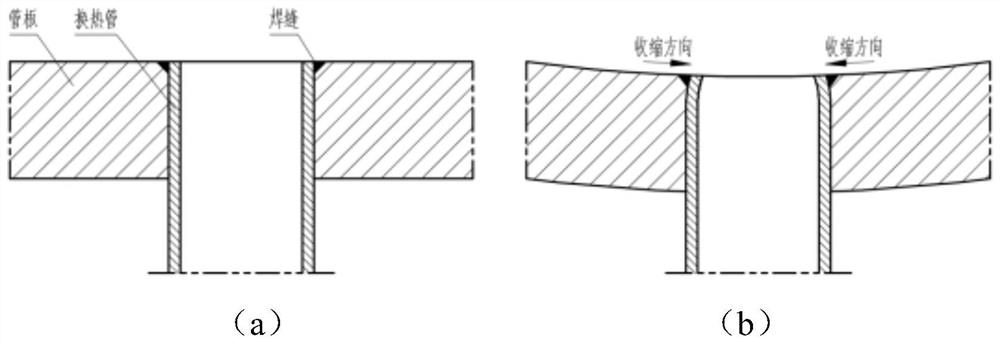

A technology for welding deformation and heat exchanger tubes, which is applied in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as poor sealing, affecting welding operations, and tube pull-off, and achieves small space occupation, convenient operation, and The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

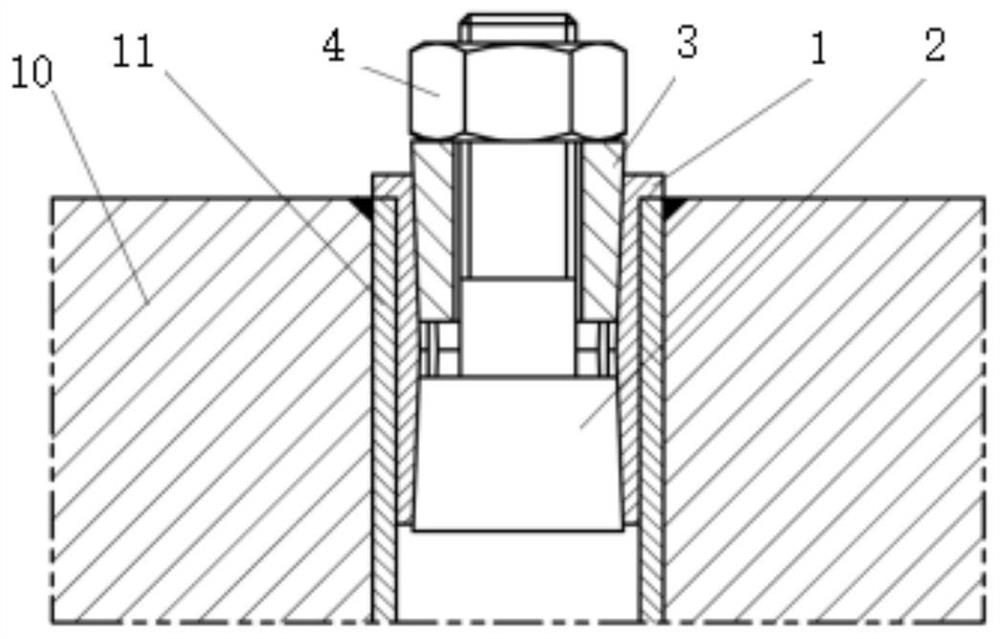

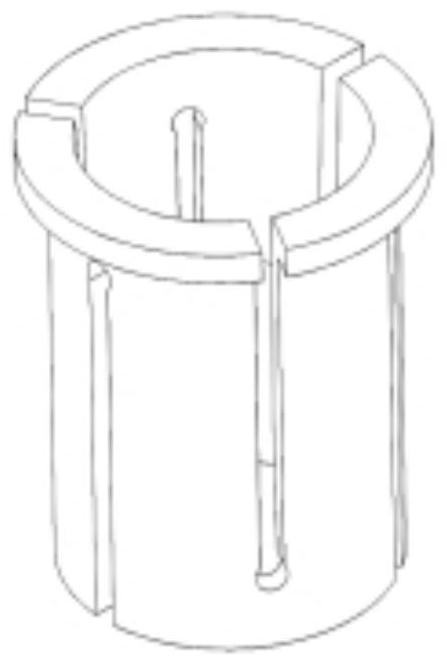

[0026] like figure 2 As shown, a tooling for suppressing welding deformation of heat exchanger tube sheets is composed of an elastic sleeve 1 , an upper conical pin 3 , a lower conical pin 2 , and a nut 4 . The elastic sleeve 1 is inserted into the tube hole after welding the heat exchange tube 11 and the tube sheet 10, the shoulder of the elastic sleeve 1 is in close contact with the nozzle, the lower conical pin 2 and the upper conical pin 3 are installed in the elastic sleeve 1, and the upper The tapered pin 3 is sleeved on the upper screw of the upper tapered pin 2, and the screw is screwed into the nut 4. By tightening the nut 4, the lower tapered pin 2 and the upper tapered pin 3 push the elastic sleeve 1 to expand outwards. The diameter becomes larger, so that the elastic sleeve 1 is in close contact with the inner wall of the heat exchange tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com