Laser-assisted cutting tool

A cutting tool and laser-assisted technology, applied in the field of precision parts processing, can solve the problems of poor improvement effect and lack of effective irradiation of materials, and achieve the effect of improving effect, improving surface quality and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

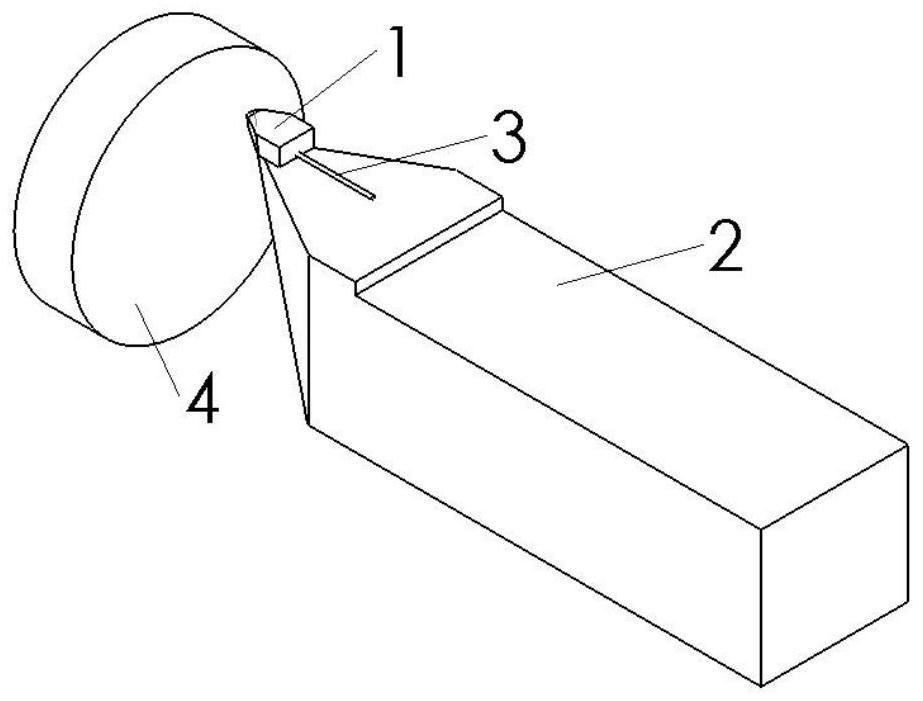

[0026] figure 1 It is a three-dimensional diagram of the structure and application scene of a laser-assisted cutting tool of the present invention, including: a tool particle 1 and a tool handle 2 . The tool holder 2 is a conventional structure, generally designed and dimensioned according to the tool holder of the machine tool, and will not be repeated here.

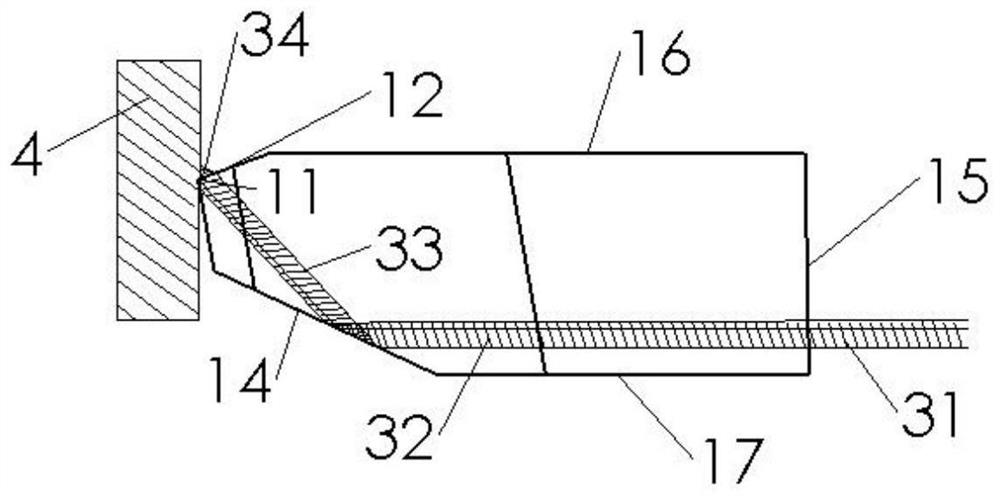

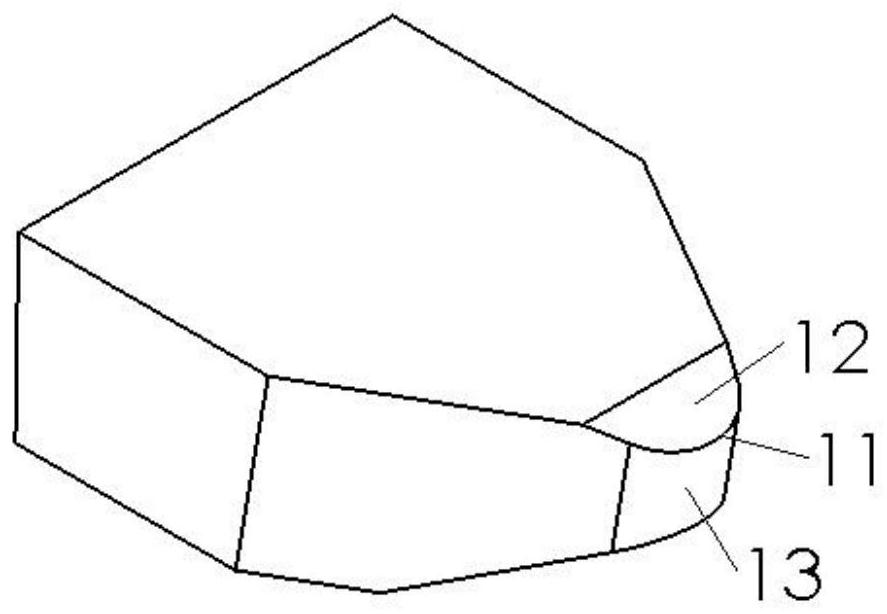

[0027] figure 2 This is a diagram of the blade structure and optical path transmission of a laser-assisted cutting tool of the present invention. The blade 1 is made of a hard laser-transmitting material, usually single crystal diamond, but is not limited to this material. The blade 1 has a special structure, including: a blade tip 11 , a rake face 12 , a flank 13 , an internal reflection surface 14 , a laser incident surface 15 , a blade top surface 16 , and a blade bottom surface 17 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com