Cutting device for chip processing

A cutting device and chip technology, which is applied in the direction of fine working devices, stone processing equipment, working accessories, etc., can solve the problems of large manual labor, low chip cutting efficiency, and many manual operation steps, and achieves automatic and fast feeding. The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

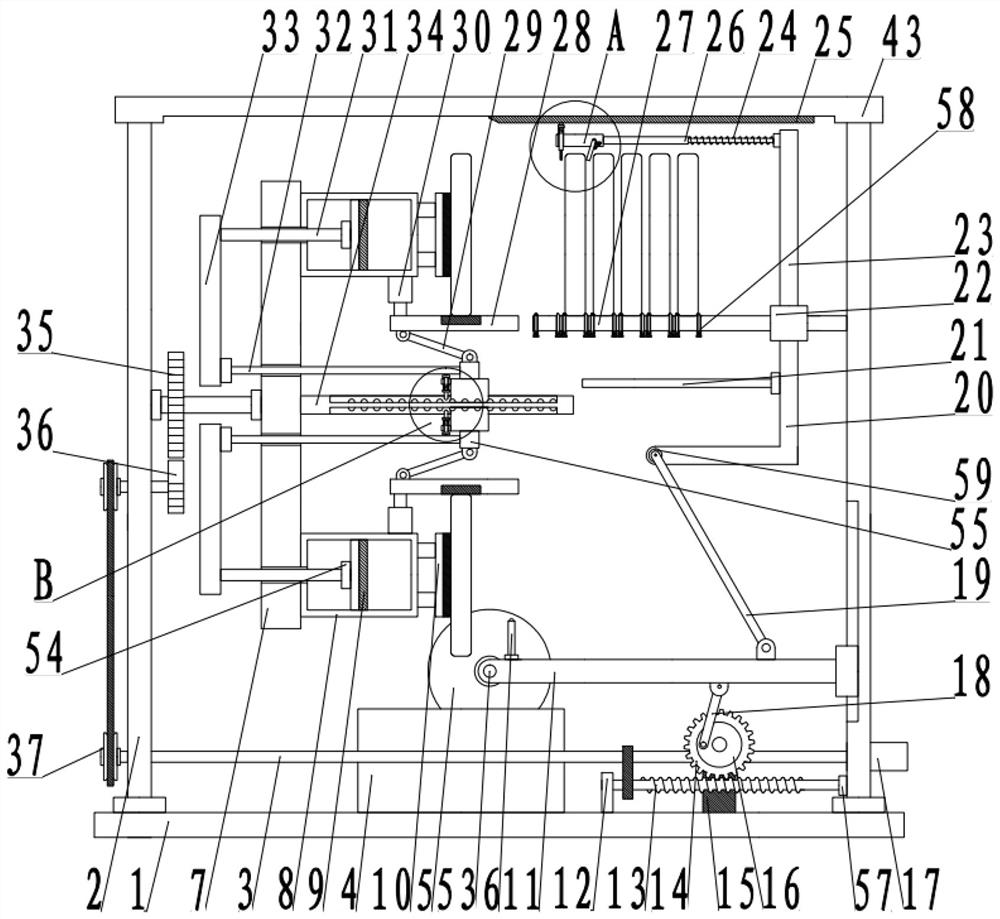

[0027] see Figure 1-6 , a cutting device for chip processing, comprising a base plate 1, and also comprising:

[0028] The enclosure plates 2 are fixedly arranged on both sides of the bottom plate 1, the top of the enclosure plate 2 is fixedly connected to the top plate 43, and one side of the enclosure plate 2 is rotatably connected to the feeding tray 7;

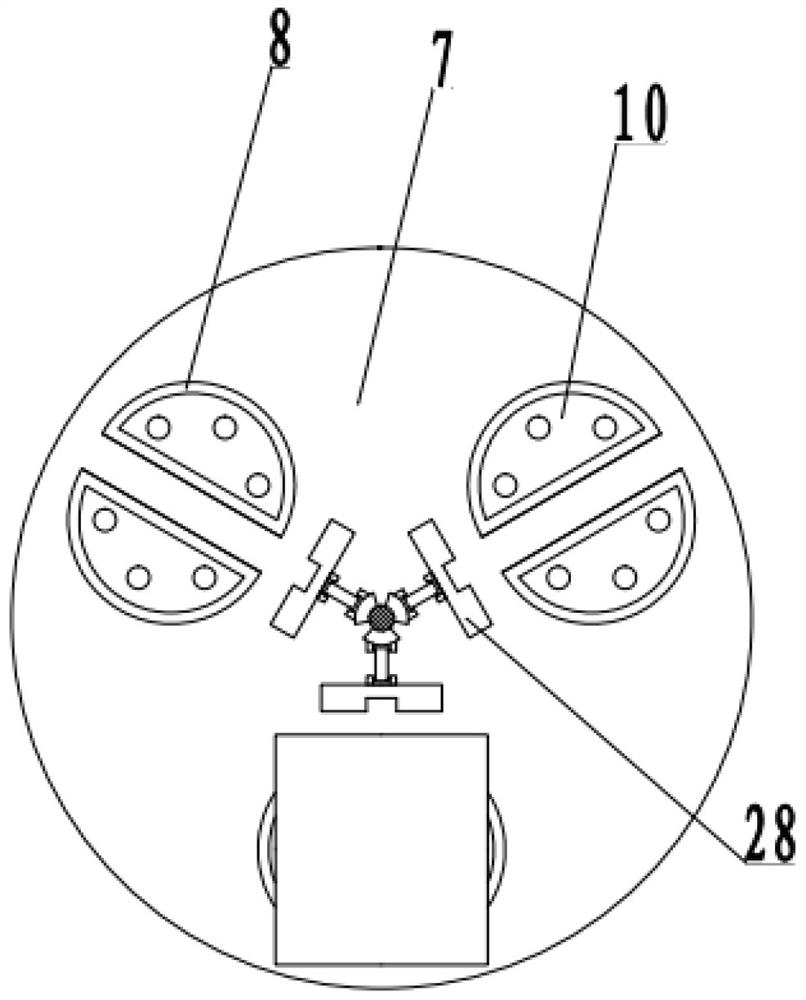

[0029]The cutting mechanism 53 arranged on one side of the feeding tray 7 includes an installation rod 11 , which is slidably connected to the side wall of the enclosure 2 , and one end of the installation rod 11 is rotatably connected to the cutting wheel 5 . The top end is fixedly connected to the push rod 6, the side wall of the feeding plate 7 is fixedly connected to the piston cylinder 8, the piston cylinder 8 is provided with a piston assembly 54, one end of the piston cylinder 8 is fixedly connected to the adsorption disk 10, and the adsorption disk 10 is provided with air holes, so The side wall of the piston cyl...

Embodiment 2

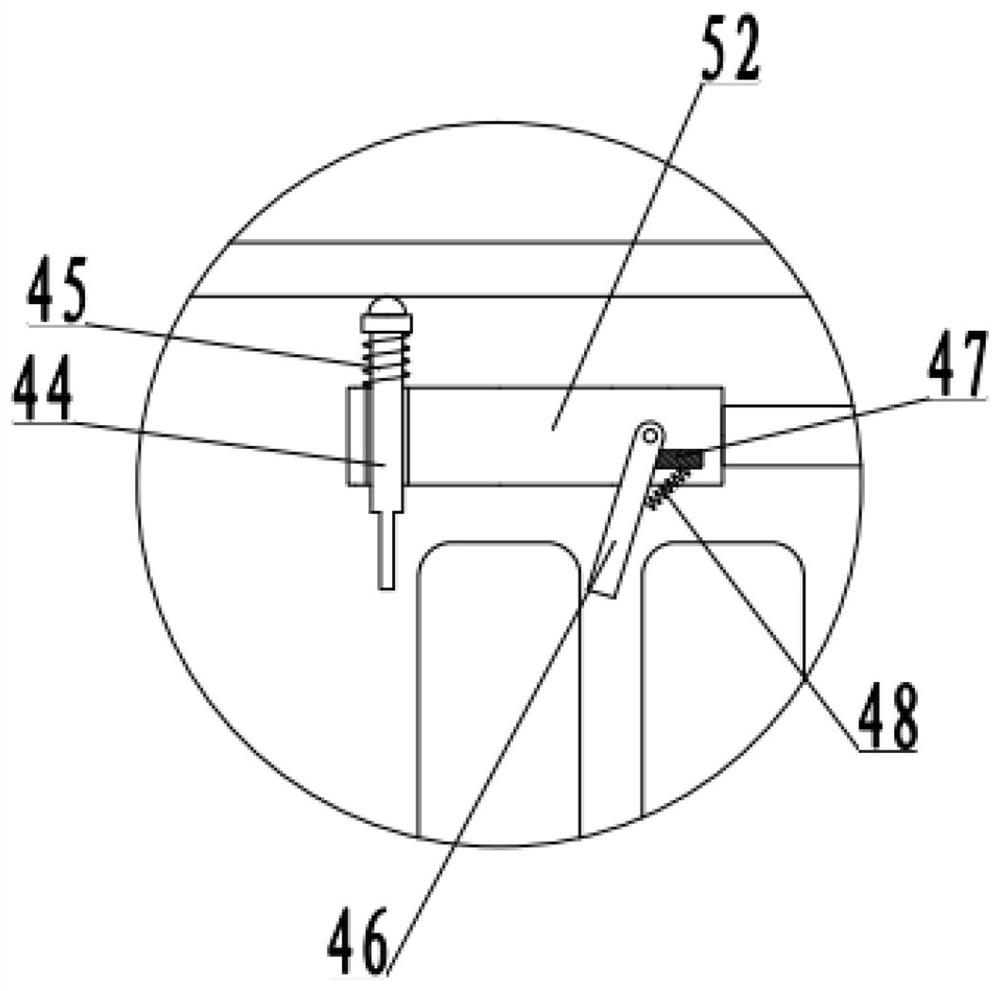

[0032] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the linkage assembly 55 includes a sliding block 39, the sliding block 39 is slidably connected with the bearing beam 34, and one end of the sliding block 39 is hinged to the linkage arm 29, and the linkage One end of the arm 29 is hingedly connected to the stopper plate 28, the bearing beam 34 on one side of the sliding block 39 is fixedly connected to the stopper protrusion 42, the side wall of the sliding block 39 is fixedly connected to the positioning block 38, and the positioning block 38 slides through A stop column 40 is provided, a telescopic piece 41 is sleeved on the stop column 40, and both ends of the telescopic piece 41 are respectively fixedly connected with the positioning block 38 and one end of the stop column 40. In actual use, the sliding block 39 moves and can pass the linkage arm 29. The stopper plate 28 is driven to move up and down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com