Brake device

A technology of braking device and brake pedal, which is applied to foot start device, bicycle brake, bicycle accessories, etc., can solve the problems of vehicle braking performance safety defects, inability to brake performance, inapplicability, etc. The effect of improved application, practicality and safety factor, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

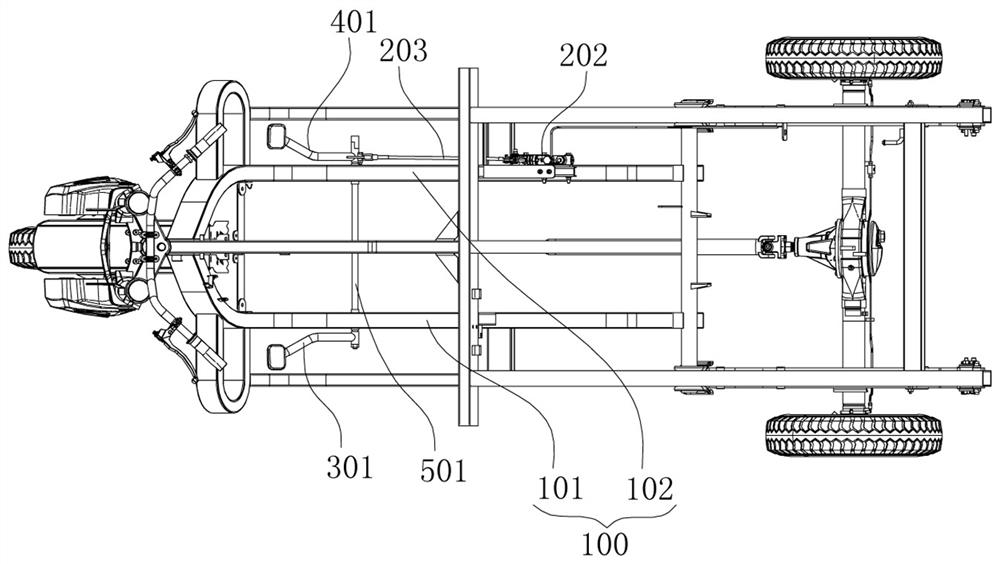

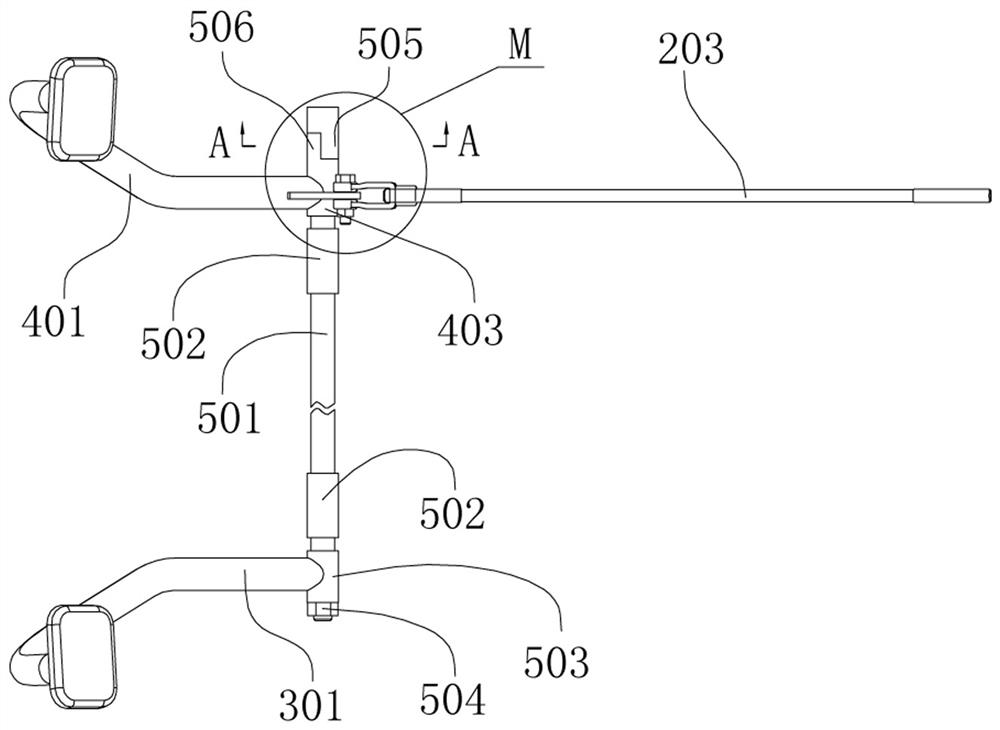

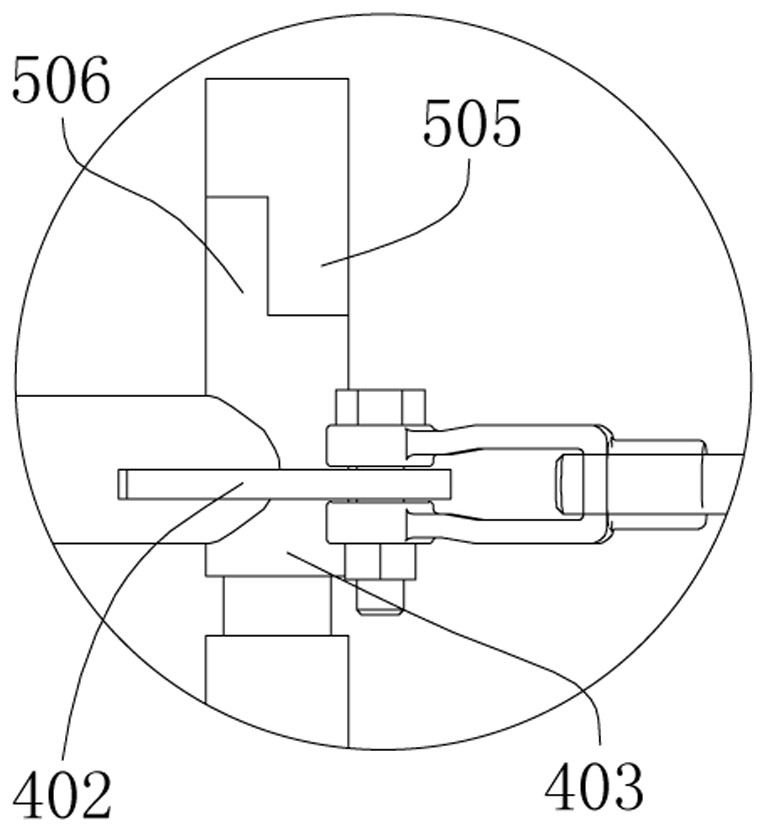

[0085] Example 1: see Figure 1-Figure 4 , the linkage mechanism of the present application includes a linkage shaft 501, and the linkage shaft 501 is rotatably connected to the frame assembly through a fixed sleeve 502. As shown in the figure, the application is provided with two fixed sleeves 502 on the linkage shaft 501, two The fixing sleeves 502 are respectively fixed on the right frame 102 and the left frame 101. The lower end of the right brake pedal 401 is fixedly connected with a right pedal sleeve 403 and is rotatably sleeved on the linkage shaft 501 through the right pedal sleeve 403. The right pedal sleeve 403 is also provided with a right pedal swing arm 402, the first end of the brake link mechanism 203 is connected with the right pedal swing arm 402, and the second end of the brake link mechanism 203 Connect to the brake. In this embodiment, by stepping on the right pedal, the right brake pedal 401, the right pedal sleeve 403 and the right pedal swing arm 402 a...

Embodiment 2

[0090] Example 2, see Figure 5 As shown: the structure in this embodiment is basically the same as that in the first embodiment, the difference lies in that the setting position of the clutch mechanism is different, the clutch mechanism in the first embodiment is arranged between the right brake pedal 401 and the linkage shaft 501, The clutch mechanism in this embodiment is arranged between the left brake pedal 301 and the linkage shaft 501; in this embodiment, the lower end of the left brake pedal 301 is fixedly connected with a left coupling sleeve 4031 and passes through the left coupling sleeve 4031 is rotatably sleeved on the left end of the linkage shaft 501, the lower end of the right brake pedal 401 is provided with a spline sleeve 503 and is meshed with the spline sleeve 503 on the right end of the linkage shaft 501 and then fastened by a nut , so that the right brake pedal 401 rotates synchronously with the linkage shaft 501, the spline sleeve 503 is also provided w...

Embodiment 3

[0092] Example 3: see Figure 6-10 , the frame assembly of the present application is provided with a right pedal shaft 404 and a left pedal shaft 304 . Specifically: the right pedal shaft 404 is arranged on the right frame 102, the left pedal shaft 304 is arranged on the left frame 101, the lower end of the right brake pedal 401 is provided with a right pedal sleeve 403 and passes through the right pedal The sleeve 403 is rotatably sleeved on the right pedal shaft 404, and a right pedal swing arm 402 is also provided on the right pedal sleeve 403; the lower end of the left brake pedal 301 is provided with a left pedal The rod sleeve 303 is rotatably sleeved on the left pedal shaft 304 through the left pedal sleeve 303, and a left pedal swing arm 302 is also provided on the left pedal sleeve 303;

[0093] The linkage mechanism of this embodiment includes a brake shaft 601, two sides of the brake shaft 601 are respectively fitted into the holes at one end of the two support sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com