Conveying control method, system and device, conveyor equipment and readable storage medium

A conveying control and conveyor technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems that the energy-saving method of belt conveyors is not comprehensive enough, and the adjustment of belt-load energy-saving control is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

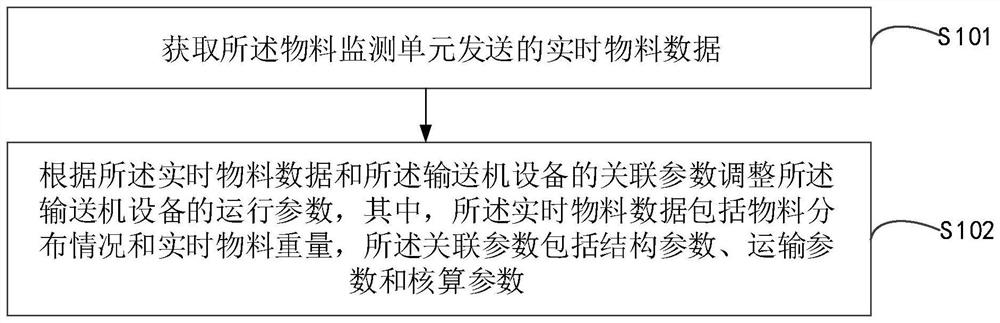

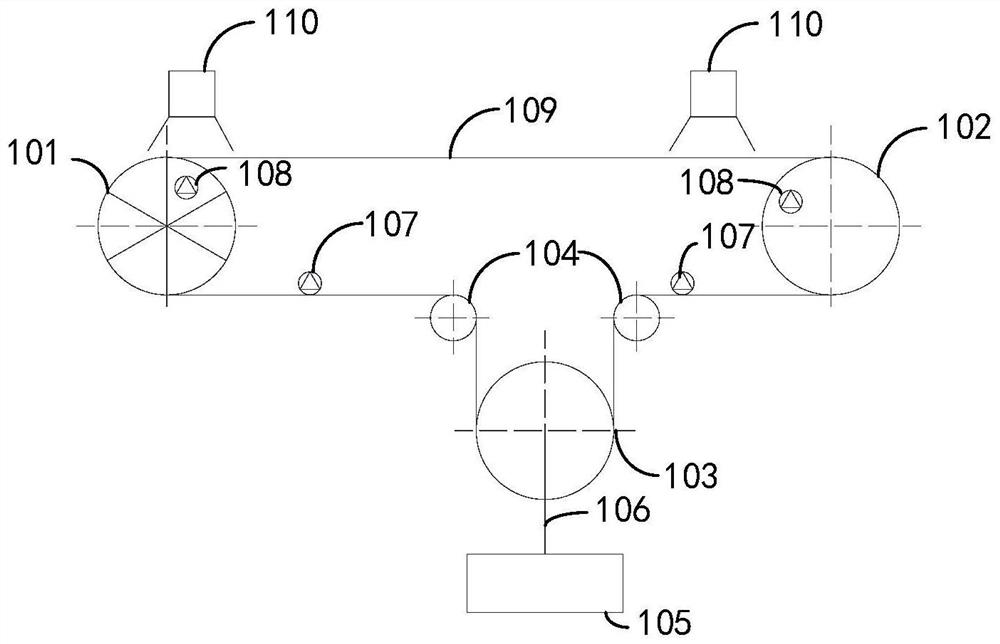

[0126] According to a specific implementation of the embodiments of the present application, the method further includes:

[0127] Calculate the emptying time according to the current running speed of the conveyor equipment and the length of the conveyor belt to be run;

[0128] Shut down after running the pullout time.

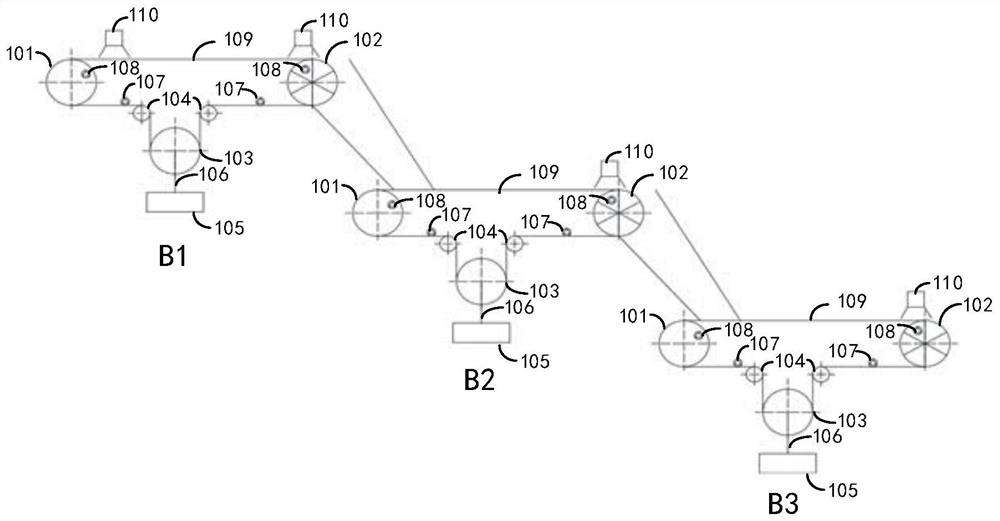

[0129] In a specific embodiment, when all the materials on the first conveyor equipment in the multi-machine conveying system have been transported, the data processing unit determines that the first conveyor equipment is in a completed state according to the material distribution and the material flow direction, The data processing unit sends an instruction to control the first conveyor equipment to stop. The downtime of the first conveyor equipment is taken as the time zero of the second conveyor equipment, and the time zero indicates that all materials have been transported to the second conveyor equipment.

[0130] The second conveyor equipment calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com