High-weather-resistance black PC resin composition as well as preparation method and application thereof

A resin composition and high weather resistance technology, which is applied in the field of high weather resistance black PC resin composition and its preparation, can solve the problems of low hydrolysis resistance stability, limit the application of polycarbonate, and poor scratch resistance, etc. Aging stability, improvement of light hydrolysis effect, effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

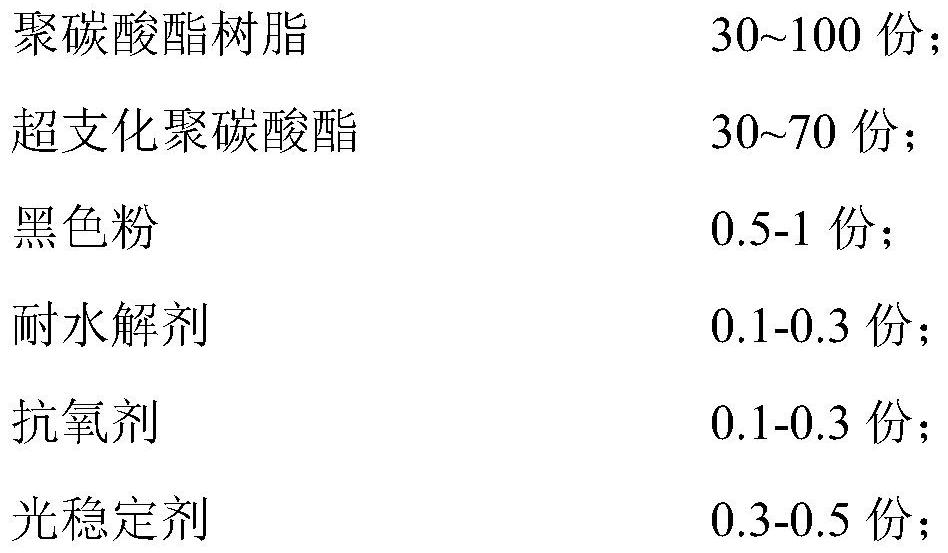

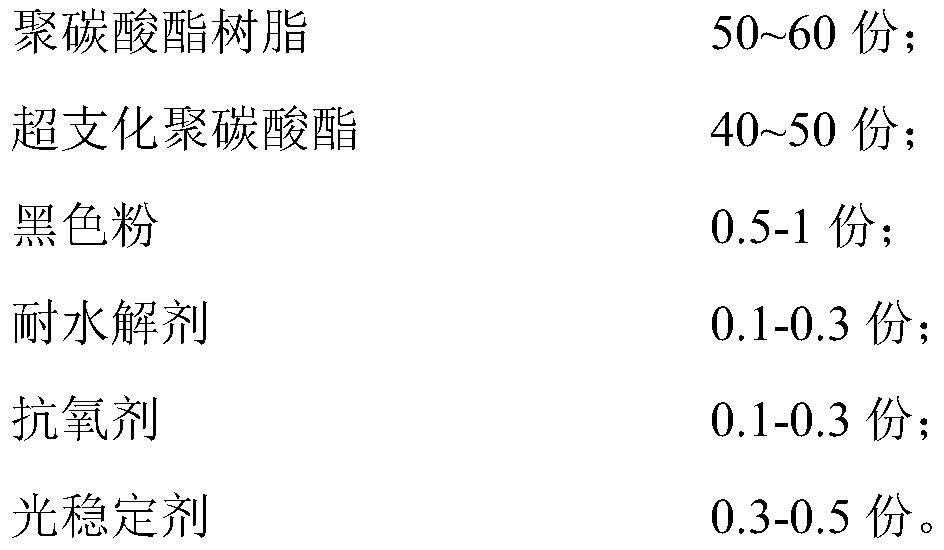

Method used

Image

Examples

Embodiment 1

[0056]A high-weather-resistant black PC resin composition, comprising the following components by weight: 160 parts of polycarbonate resin, 140 parts of hyperbranched polycarbonate, 1 part of organic high-gloss black powder, 0.3 part of hydrolysis-resistant agent, anti-hydrolysis agent Oxygen agent 0.3 part, light stabilizer 0.5 part, lubricant 0.2 part.

Embodiment 2

[0058] A high-weather-resistant black PC resin composition, comprising the following components by weight: 130 parts of polycarbonate resin, 170 parts of hyperbranched polycarbonate, 1 part of organic high-gloss black powder, 0.1 part of hydrolysis-resistant agent, Antioxidant 0.1 part, light stabilizer 0.3 part, lubricant 0.1 part.

Embodiment 3

[0060] A high-weather-resistant black PC resin composition, comprising the following components by weight: 1100 parts of polycarbonate resin, 130 parts of hyperbranched polycarbonate, 1 part of organic high-gloss black powder, 0.3 part of hydrolysis-resistant agent, anti-hydrolysis agent Oxygen agent 0.3 part, light stabilizer 0.5 part, lubricant 0.2 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com