Cobalt-containing composite coating for steel cord and preparation method of cobalt-containing composite coating

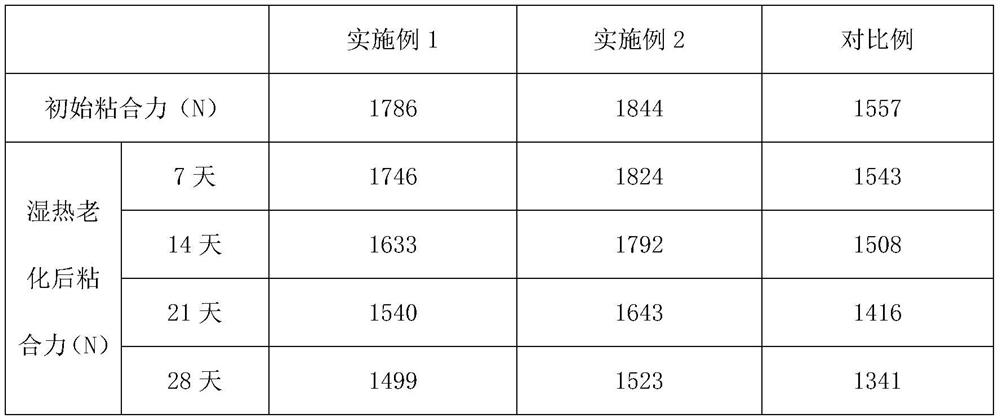

A composite coating and steel cord technology, applied in the field of metal product coating, can solve the problem of not being able to reduce the use of Co element in rubber products, not increasing the initial adhesion between Cu-Zn-Co coating and rubber, and not being able to have better performance. Wet heat aging adhesion performance and other problems, to achieve the effect of superior wet heat aging adhesion performance, shorten the preparation time, and increase the initial adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A cobalt-containing composite coating for steel cords and a preparation method thereof, the specific preparation method steps are as follows:

[0026] Step 1: The person in charge of the coating production technology conducts a joint review of the preparation plan, asks questions and answers, and the technical staff prepares a special preparation plan and pays attention to details, and makes technical disclosures to the staff;

[0027] Step 2: Use the sand bag grinding tool to carry out overall rough grinding and surface fine grinding treatment on the steel cord steel wire substrate;

[0028] Step 3: Purging the surface of the grinding scum on the surface of the steel cord steel wire matrix through high-pressure gas;

[0029] Step 4: spray Cu and Mo powders on the surface layer of the cleaned steel wire substrate, and heat and solidify to prepare a CuMo base layer;

[0030] Step 5: Use a reactive plasma spray gun to spray Zn / Si powder on the CuMo base layer to prepare ...

Embodiment 2

[0040] A cobalt-containing composite coating for steel cords and a preparation method thereof, the specific preparation method steps are as follows:

[0041] Step 1: The person in charge of the coating production technology conducts a joint review of the preparation plan, asks questions and answers, and the technical staff prepares a special preparation plan and pays attention to details, and makes technical disclosures to the staff;

[0042] Step 2: Use the sand bag grinding tool to carry out overall rough grinding and surface fine grinding treatment on the steel cord steel wire substrate;

[0043] Step 3: Purging the surface of the grinding scum on the surface of the steel cord steel wire matrix through high-pressure gas;

[0044] Step 4: spray Cu and Cr powder on the surface layer of the dried steel wire substrate, and heat and solidify to prepare a CuCr base layer;

[0045] Step 5: spray Zn / Si powder on the CuCr base layer with a reactive plasma spray gun to prepare a SiZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com