Fireproof window

A fireproof window and fireproof rubber strip technology, applied in the field of fireproof windows, can solve the problems of inability to reliably prevent fire and smoke, unable to maintain structural integrity, poor structural stability, etc., to achieve excellent fireproof integrity, improve structural stability, and resist Good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be further described with reference to the accompanying drawings and specific embodiments. It should be noted that, on the premise of no conflict, the embodiments or technical features described below can be arbitrarily combined to form new embodiments. .

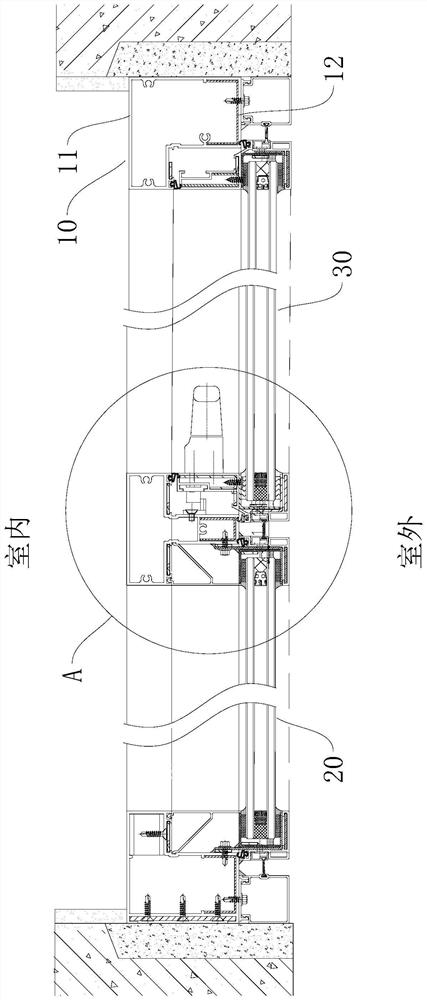

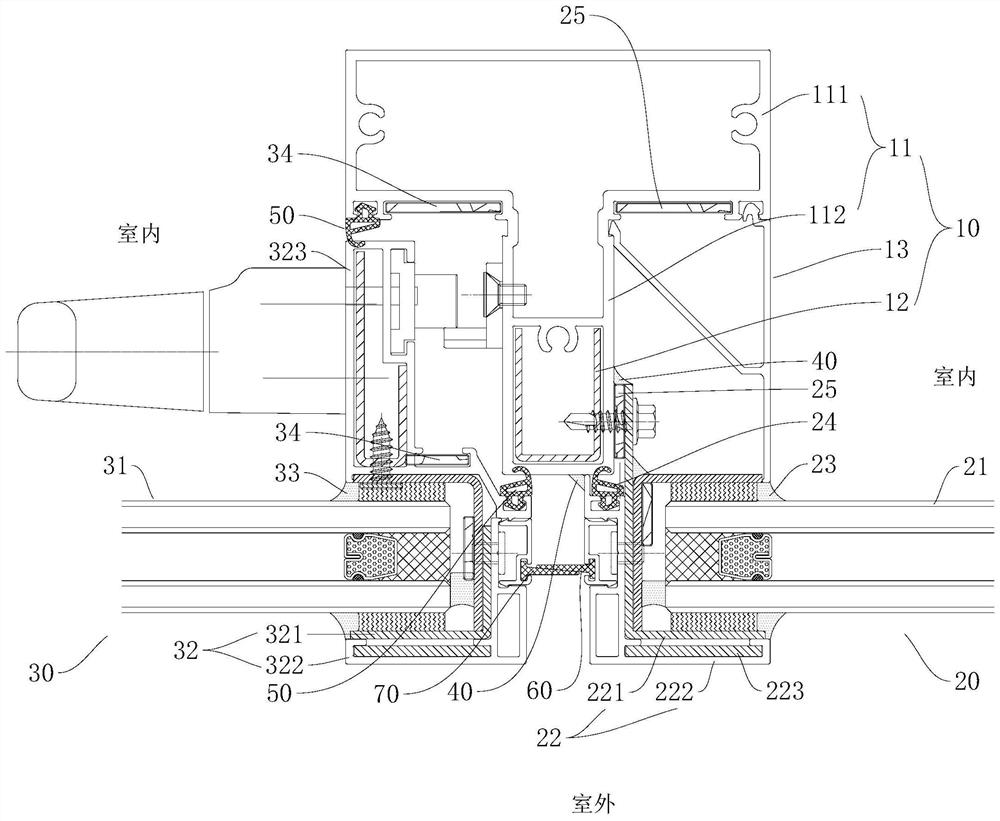

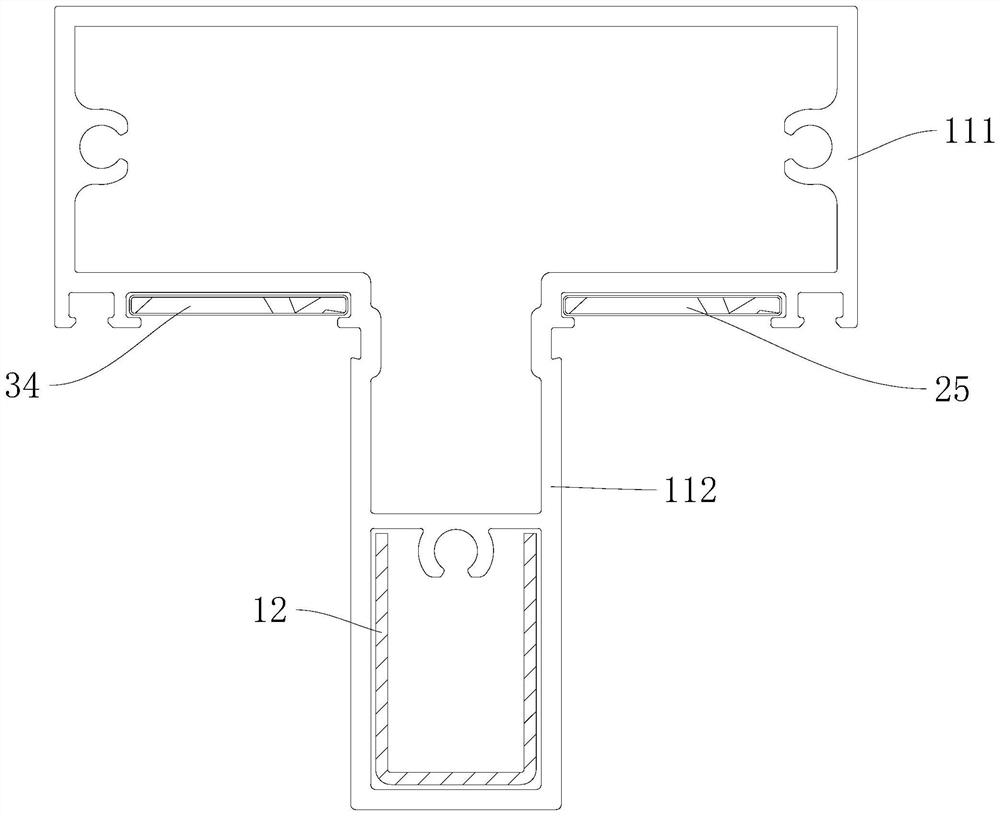

[0039] see Figure 1-Figure 2 , shows a fireproof window according to a preferred embodiment of the present invention, comprising: a window frame 10, the window frame 10 includes a keel base 11 made of aluminum alloy and a first steel member 12 arranged in the keel base 11, The keel base 11 is provided with a first window and a second window; the fixed window sash 20 is fixed on the window frame 10 and closes the first window, and a first fireproof sealant 40 is arranged between the window frame 10; the movable window sash 30, It is hinged on the window frame 10 and can be locked on the window frame 10 to close or open the second window. A first fireproof rubber strip 50 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com