System and method for controlling running distance of delivery pump

A control system and delivery pump technology, applied in the field of delivery pumps, can solve problems such as high cost of delivery pumps, cumbersome management, and wrong message transmission, and achieve better management effects, improved execution efficiency, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

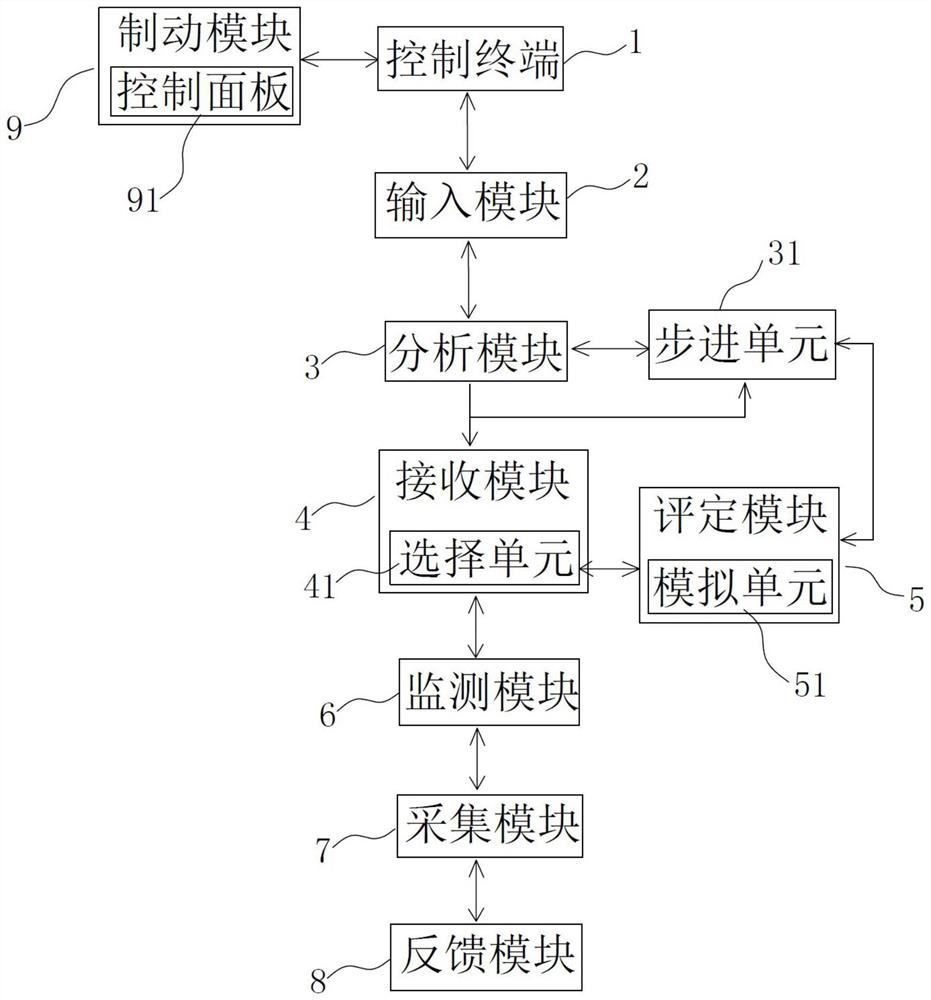

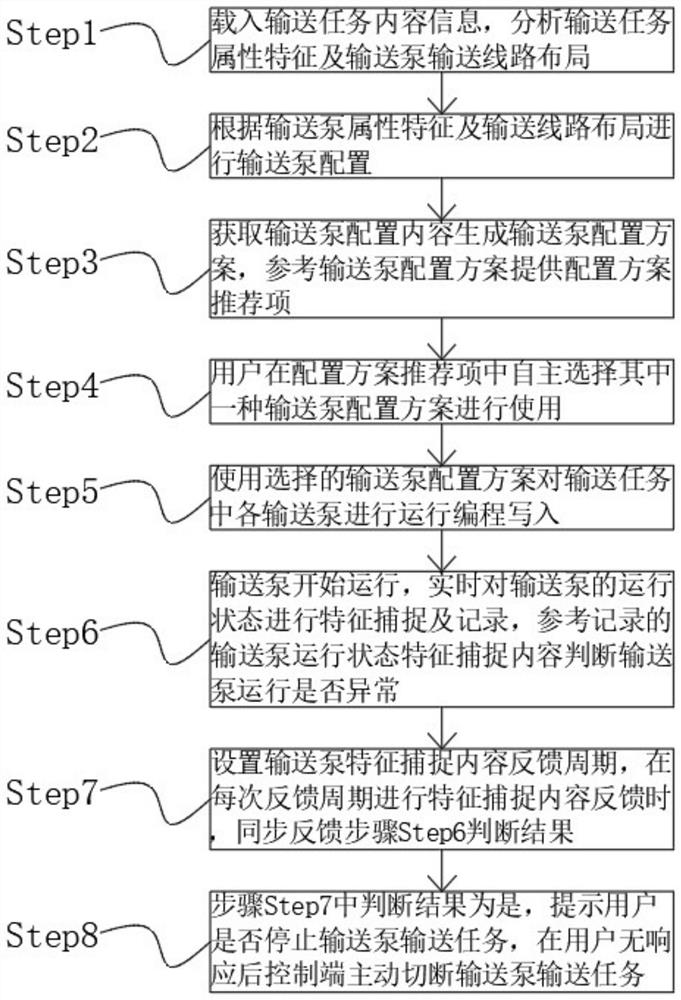

[0047] A system and method for controlling the running distance of a delivery pump in this embodiment, such as figure 1 shown, including:

[0048] Control terminal 1 is the main control terminal of the system, used to issue execution commands for lower-level modules to start and execute;

[0049] The input module 2 is controlled and started by the control terminal 1, and is used to input the task content that the system is about to run;

[0050] The analysis module 3 is used for receiving the task content input by the input module 2, and extracts the task feature in the task content;

[0051] The receiving module 4 is used to receive the data information obtained by the total operation of the analysis module 3 and the stepping unit 31, and package and send it to the selection unit 41 electrically connected to the medium;

[0052] The monitoring module 6, selects the delivery pump configuration scheme in the selection unit 41, and triggers the operation synchronously after th...

Embodiment 2

[0059] At the specific implementation level, on the basis of Embodiment 1, this embodiment refers to figure 1 As shown in the embodiment 1, the operation distance control system of the delivery pump is further specified, as figure 1 As shown, the task features extracted in the analysis module 3 include the delivery volume of the delivery pump, the quantity route of the delivery pump, the delivery target category of the delivery pump, and the delivery order of the delivery pump.

[0060] like figure 1 As shown, the analysis module 3 is electrically connected with the step unit 31 through the medium, and the step unit operation refers to the logic of the analysis module 3, and is used to obtain the delivery pump delivery volume, delivery pump quantity route, delivery pump delivery volume obtained in the module 3 Target category and delivery pump delivery sequence, use delivery pump delivery volume, delivery pump quantity route, delivery pump delivery target category and deliver...

Embodiment 3

[0065] At the specific implementation level, on the basis of Embodiment 2, this embodiment refers to figure 1 As shown in the embodiment 2, the operation distance control system of the delivery pump is further specified, as figure 1 As shown, the stepping unit 31 triggers the evaluation module 5 by transmitting an electrical signal through the medium, and the evaluation module 5 is electrically connected to the medium with sub-modules, including:

[0066] The simulation unit 51 is the operation logic module of the evaluation module 5, and is used for simulating the operation of each delivery pump configuration scheme in the same current operation task, and the simulation unit 51 synchronously generates a report file of the simulated operation of each delivery pump configuration scheme after the operation is finished;

[0067] Among them, the contents recorded in the report document include the operation stability of each delivery pump configuration scheme and the aging value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com