Method and system for detecting near-surface cracks of bipolar plate made of graphite

A detection system and bipolar plate technology, applied in the direction of material magnetic variables, etc., can solve problems such as transverse cracking of graphite plate products, and achieve the effect of complete functions, ensuring universality, and improving the requirements of various performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

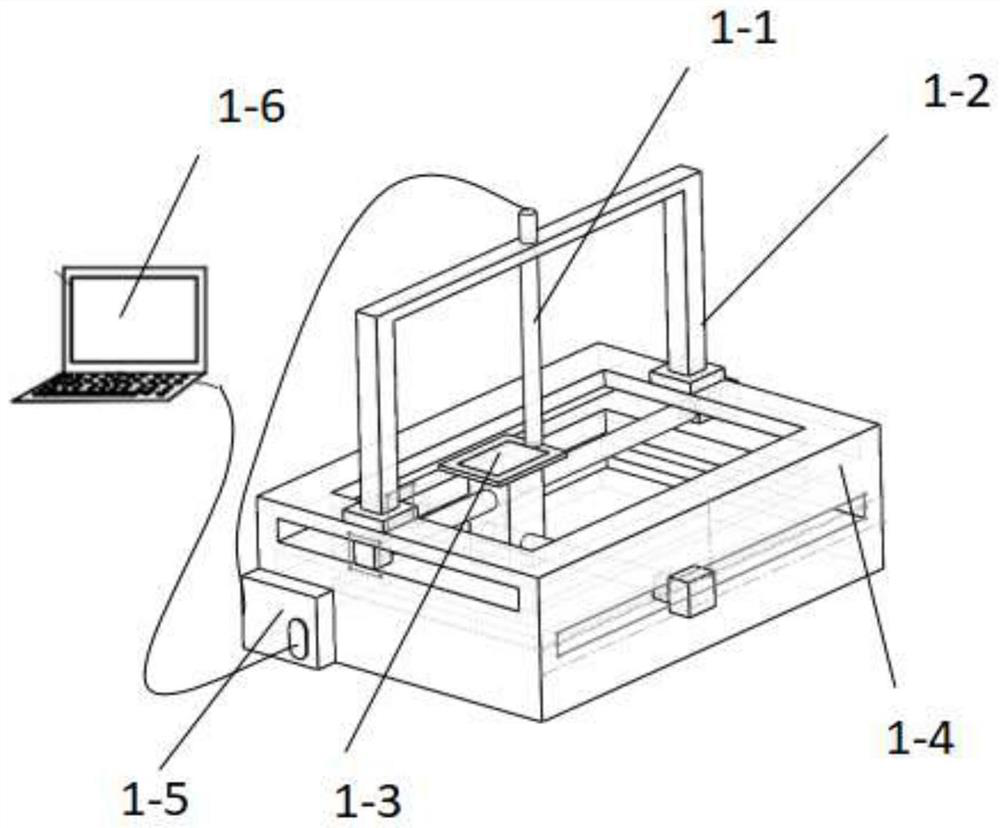

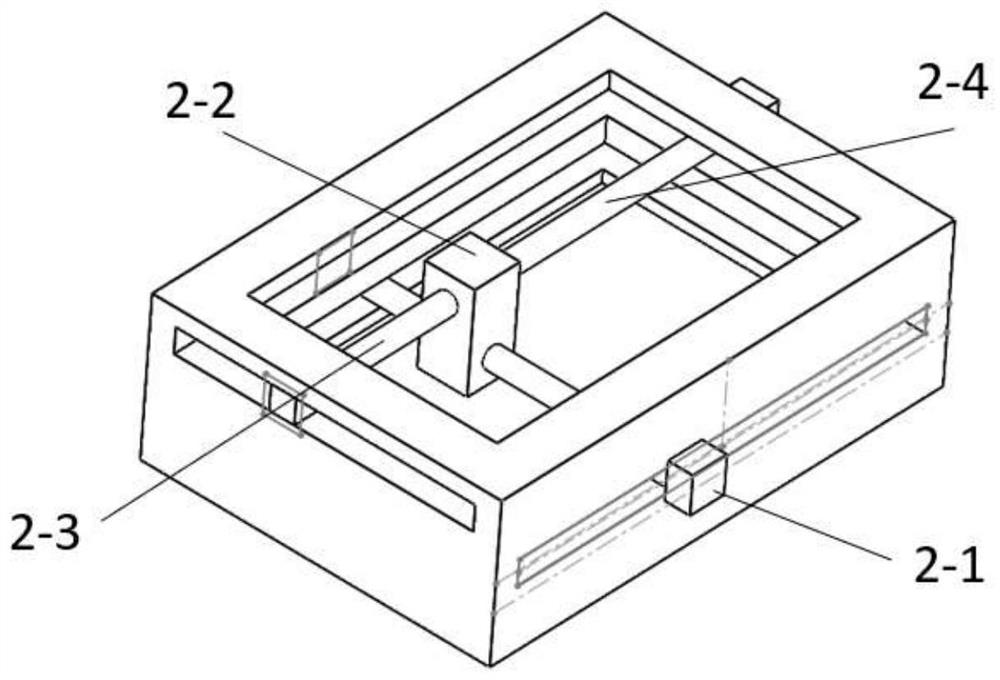

[0023] 1) First install the eddy current sensor 1-1 and fix it on the support rod 1-2. Select a graphite plate of a certain specification and the corresponding graphite plate placement device 1-3, and fix it on the connection structure 2-2 by screws.

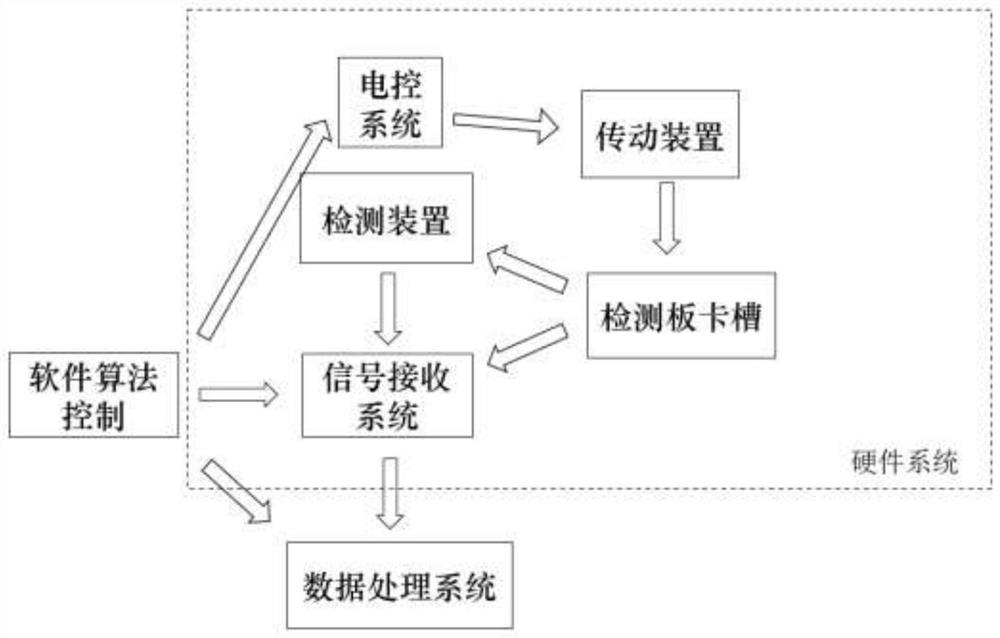

[0024] 2) Before the measurement work, it is first necessary to match the physical space coordinates with the coordinates of the positioning result of the host computer program interface. Input the length Y width X of the graphite plate and the installation height Z of the eddy current sensor to the upper computer, and the upper computer system will automatically match the graphite plate displacement algorithm according to the position conversion, so as to realize the matching between the coordinates of the system output graphite plate and its physical space position coordinates .

[0025] 3) Click the detection button on the upper computer of the computer, the system starts to run, the eddy current sensor is stationary, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com