Corn straw crushing device based on fertilizer production

A corn stalk and crushing device technology, applied in the application, biological organic part treatment, agricultural machinery and implements and other directions, can solve the problems of large deflection and flexibility, hard texture of the stem part, and partial winding of the stalk, so as to eliminate the winding shaft. , Improve fermentation efficiency and complete crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

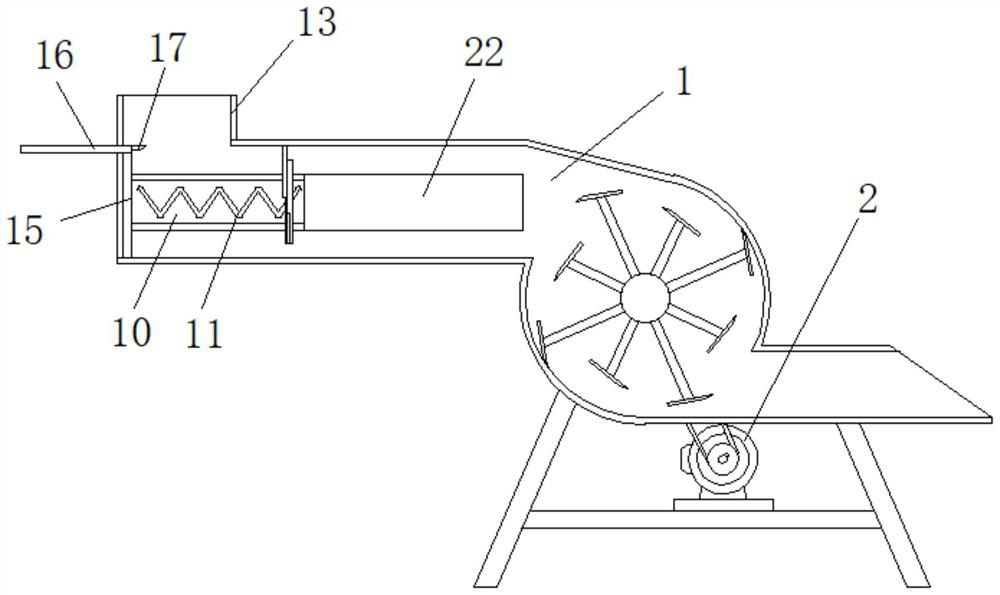

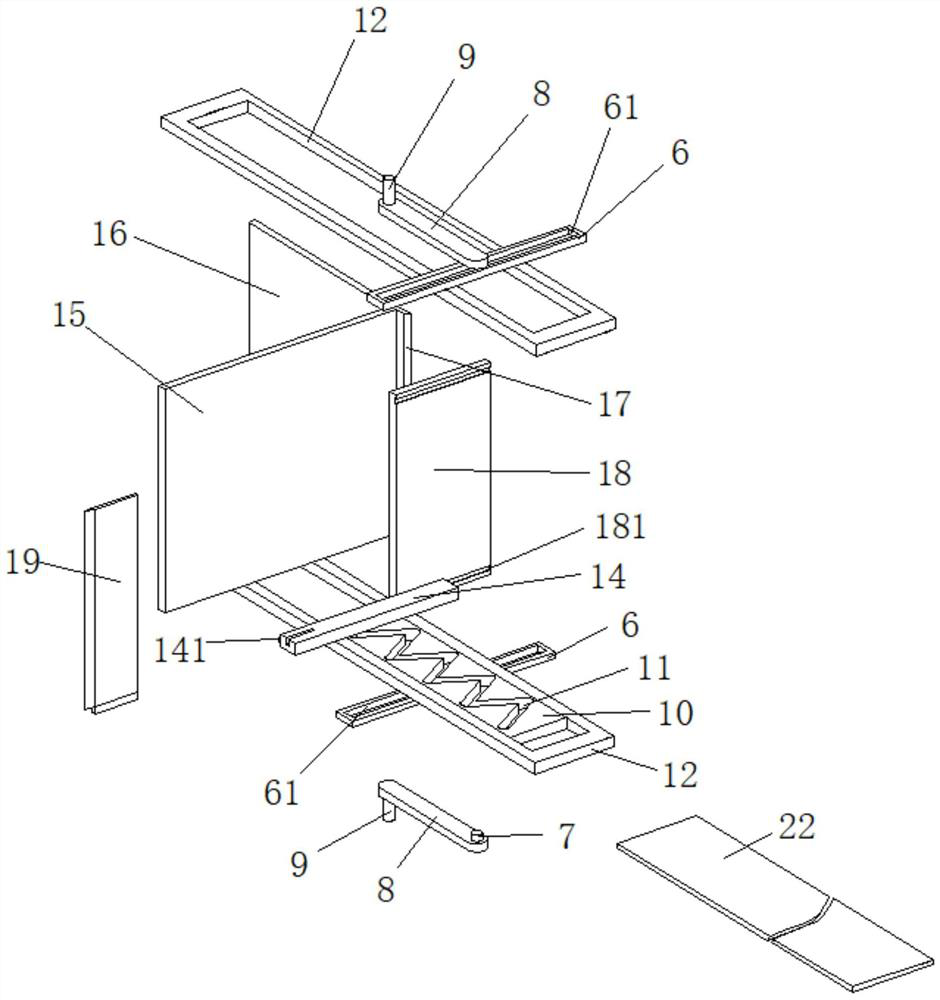

[0019] see Figure 1-5 , This specific embodiment is realized by the following technical solutions, which includes a rotary shaft pulverizer 1; the rotary shaft pulverizer 1 is installed with a double output shaft motor 2, and the feed port of the rotary shaft pulverizer 1 is installed with guillotine mechanism;

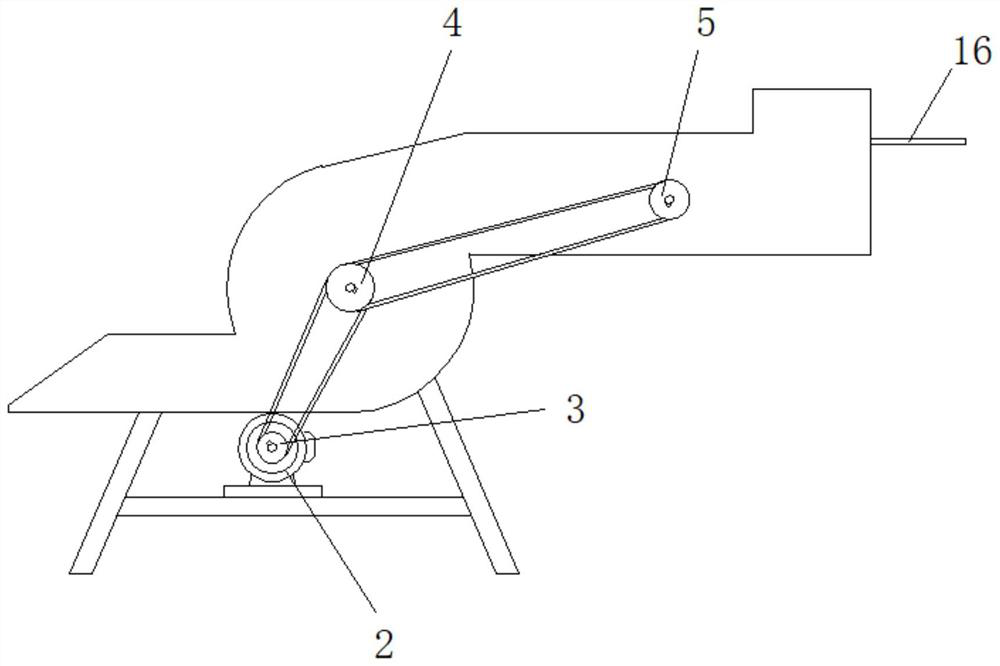

[0020] The two ends of the double output shaft motor 2 are respectively equipped with driving pulleys 3. The driving pulleys 3 are driven and matched with the secondary pulleys 4 on the pulverizing shaft end of the rotary shaft crusher 1 through a V-belt. The passing V-belt of the wheel 4 is matched with the driven pulley 5 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com