Dehydration treatment equipment for anhydrous acetonitrile and treatment process thereof

A treatment equipment and acetonitrile technology, which is applied in the chemical industry, carboxylic acid nitrile purification/separation, sustainable manufacturing/processing, etc., can solve the problems of poor acetonitrile dehydration effect, achieve good dehydration effect, simple process, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

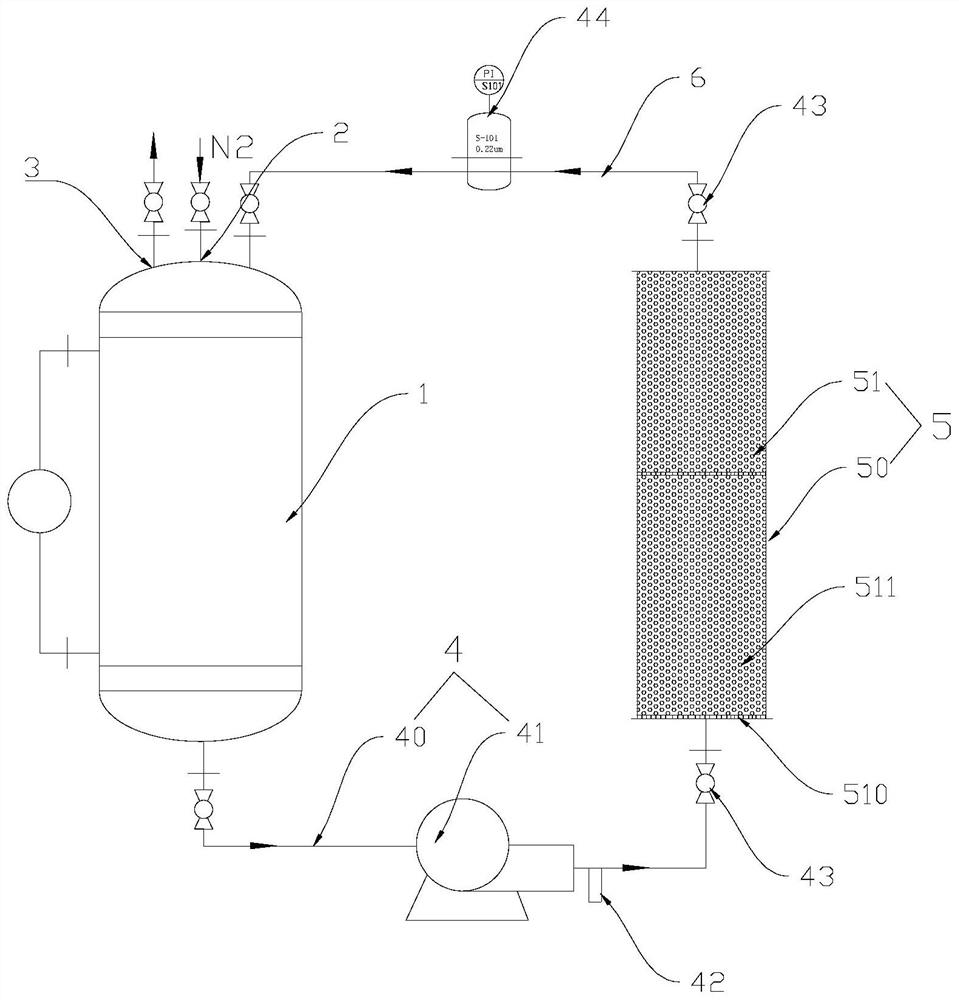

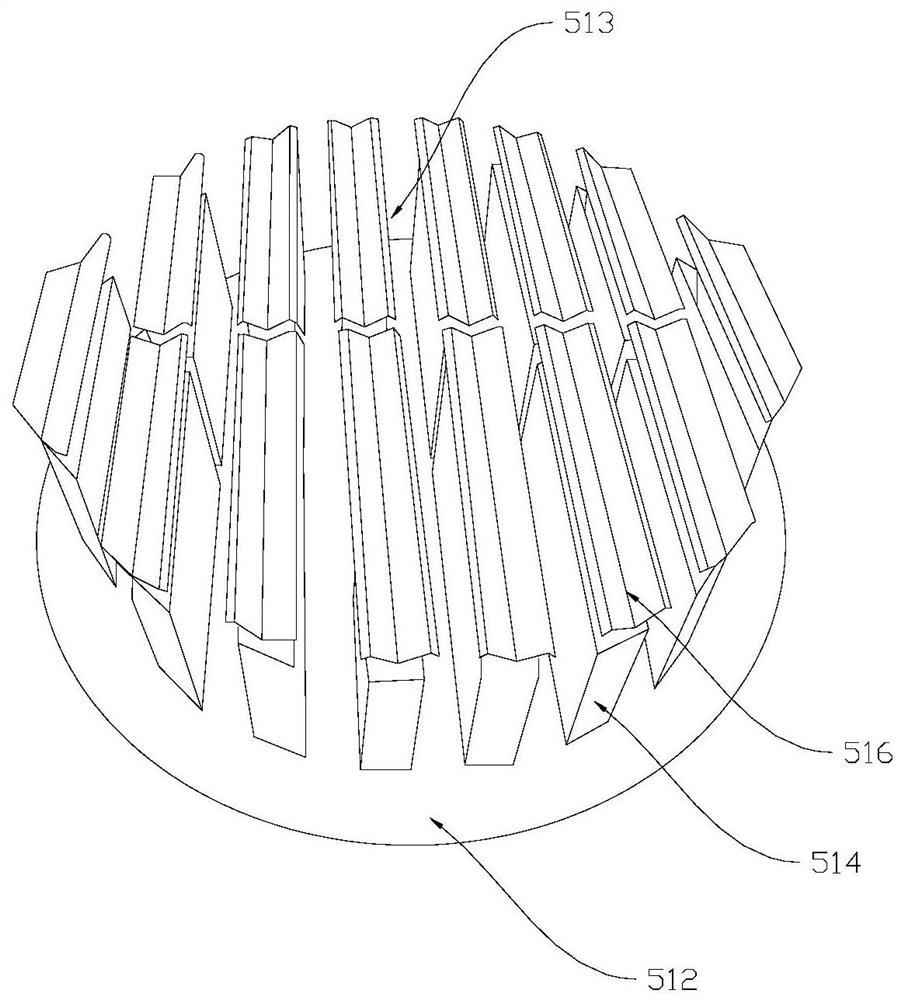

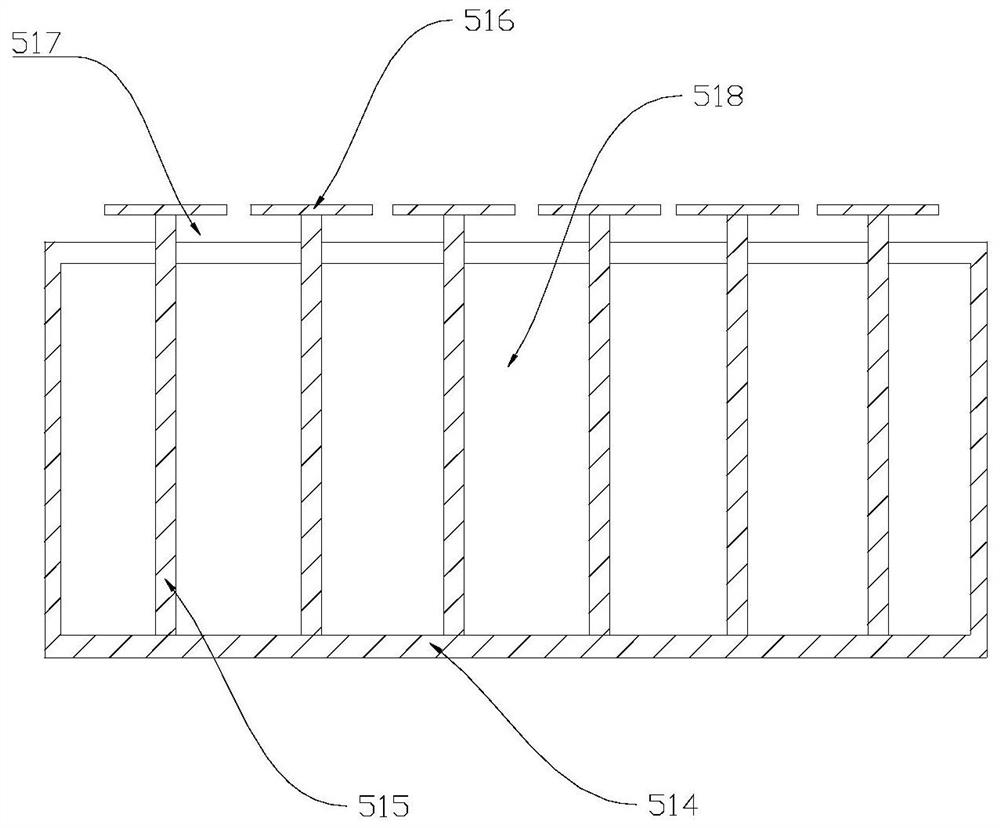

[0025] like figure 1 As shown, a dehydration treatment equipment for anhydrous acetonitrile includes a raw material tank 1, an air inlet 2 and an exhaust port 3 respectively arranged at the top of the raw material tank 1, and a discharge port connected to the raw material tank 1 through a conveying assembly 4 The dehydration mechanism 5 at the mouth and the circulation pipe 6 connected to the outlet of the dehydration mechanism 5. The outlet of the circulation pipe 6 is connected to the circulation inlet of the raw material tank 1. The raw material tank 1, the conveying assembly 4, the dehydration mechanism 5 and the circulation pipe 6 are formed. Circulation line for dehydration of acetonitrile. The air inlet 2 is connected with a nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com