Steel pipe brushing equipment and brushing method thereof

A steel pipe and brushing technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of high construction cost, manual brushing, and unstable brushing quality, so as to reduce labor costs and improve brushing quality. Stable and improved brushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the related invention, but not to limit the invention. In addition, it should be noted that, for the convenience of description, only the parts related to the invention are shown in the drawings.

[0038] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present application will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

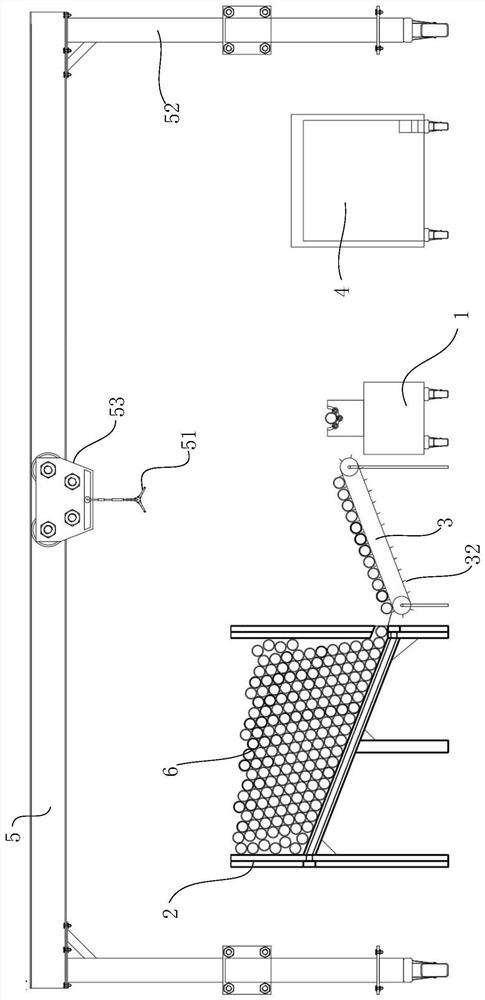

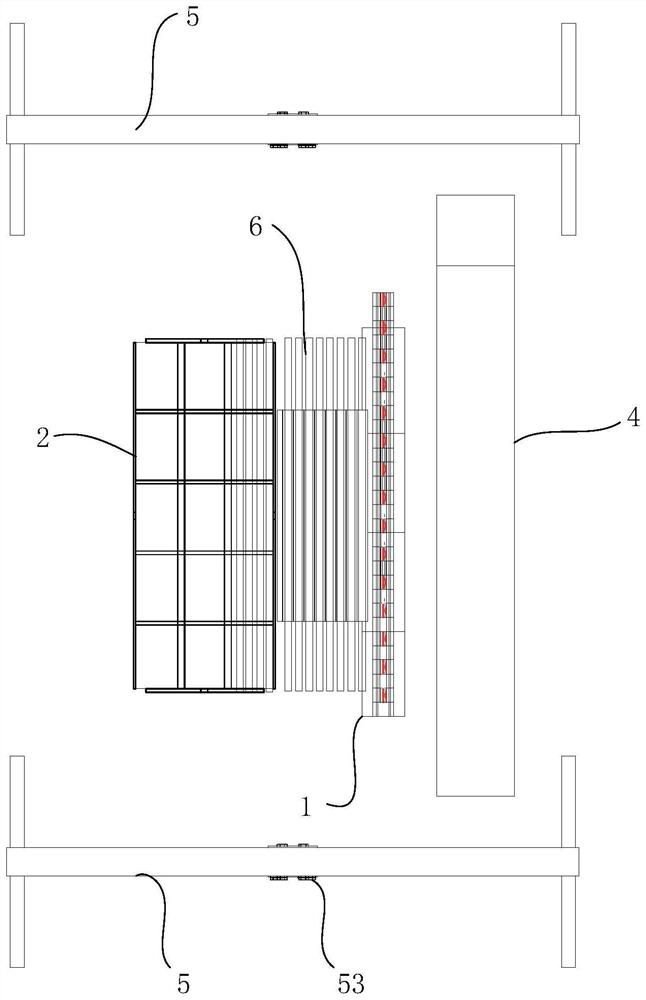

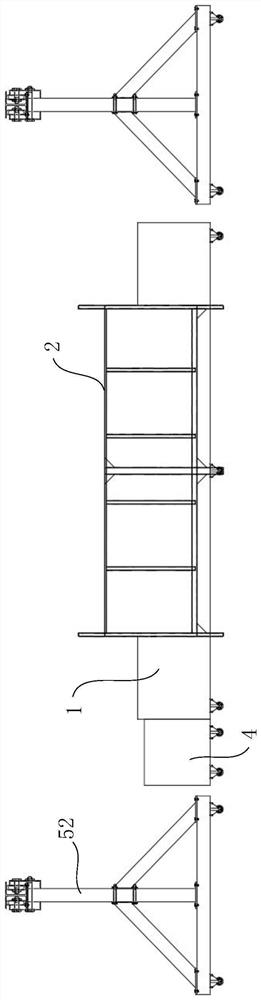

[0039] refer to Figure 1 to Figure 11 As shown, the present invention provides a steel pipe brushing equipment, including: a brushing device 1 , a storage tank 2 , a belt conveyor 3 , a drying device 4 and a guide rail 5 .

[0040] The brush tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com