Steel plate punching machine

A punching machine and steel plate technology, applied in the field of steel plate processing, can solve problems such as low punching efficiency, large hole position deviation, and steel plate warpage, meet the requirements of flatness, reduce scrap plate rate, and small hole position deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

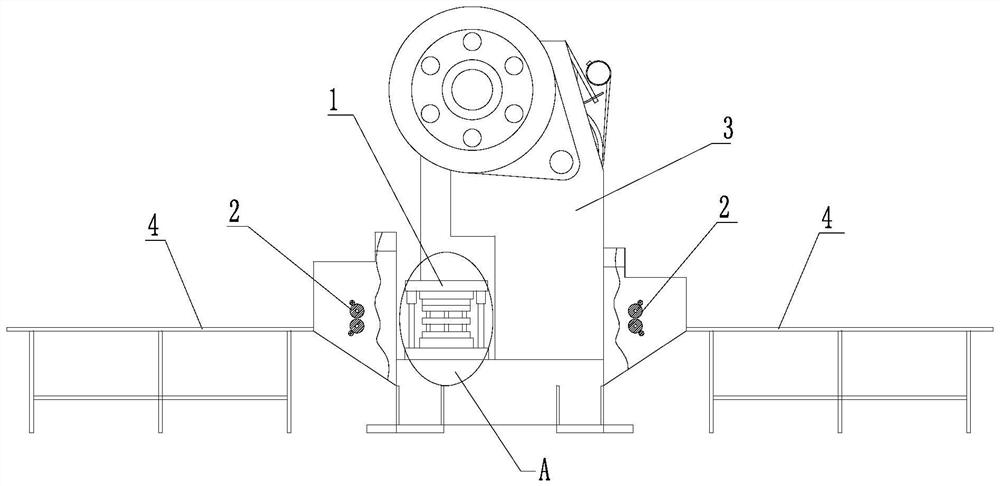

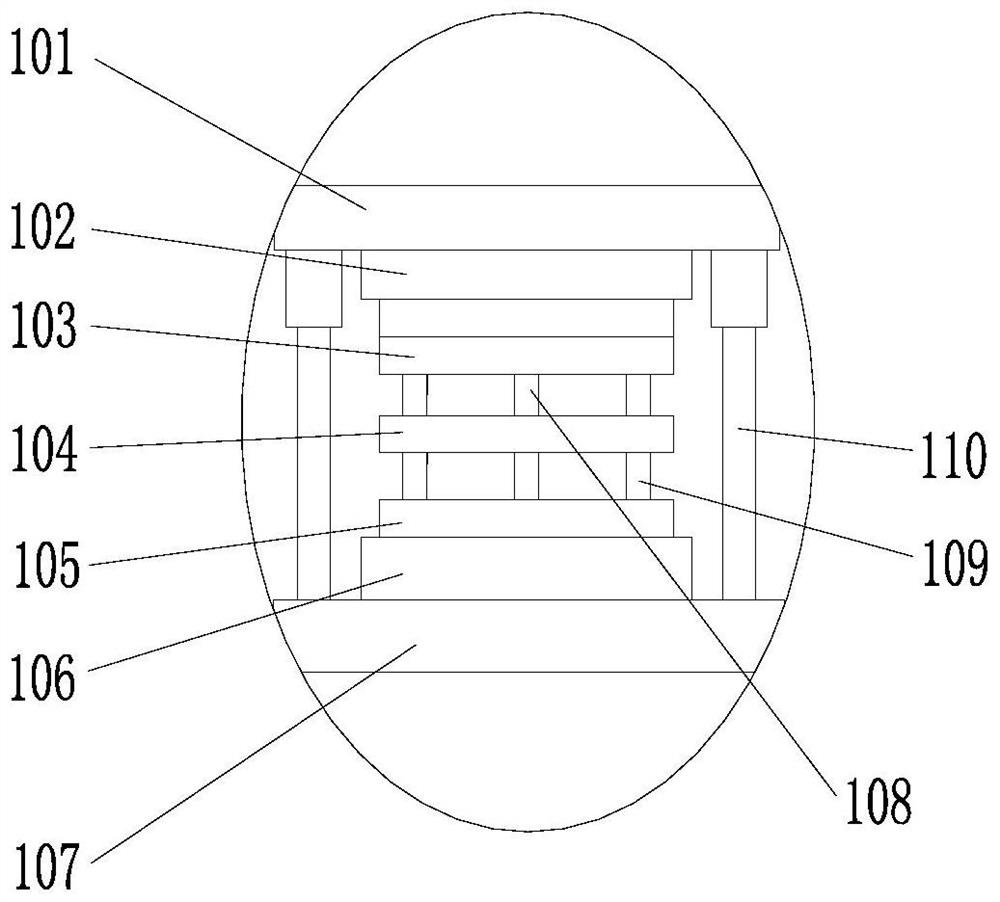

[0024] A steel plate punching machine includes a frame 3 and a punching device 1, the punching device is installed on the frame; the punching device includes a punching die, and the punching die includes an upper die base 102, an upper die assembly, a return plate 104, a lower die 105. The lower die base 106, the upper die assembly includes a stamping plate 103 and a punching needle 108, the upper die base, the stamping plate, the stripping plate, the lower die and the lower die base are arranged in order from top to bottom, and the stamping plate is fixedly connected to the upper The die base, the stripping plate is fixedly connected to the lower die, and the lower die is fixedly connected to the lower die base; a plurality of mounting holes are opened on the stamping plate, the mounting holes penetrate the stamping plate up and down, the number of punching pins is multiple, and the punching pins are connected through the mounting holes On the punching plate, the withdrawal pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap