Auxiliary loading device for ceramic wine bottle production

A loading device and ceramic wine bottle technology, which is applied in biological packaging, transportation and packaging, and packaging item types, etc., can solve the problems of increasing damage to ceramic wine bottles, shaking of the workbench, and inconvenient use, so as to improve the effect of limit fixation, Guaranteed stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

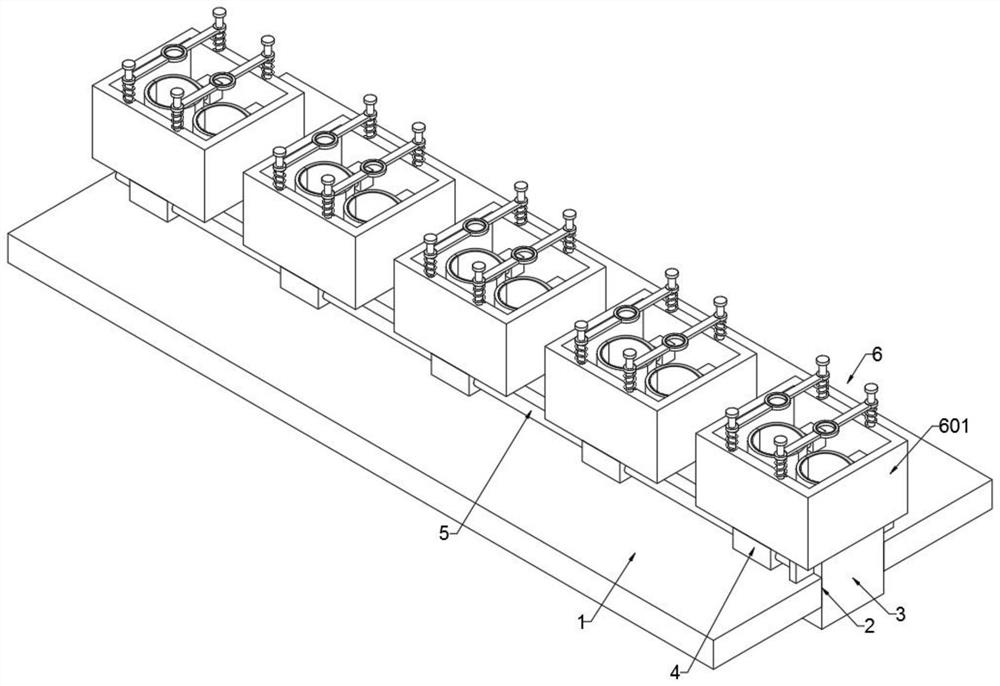

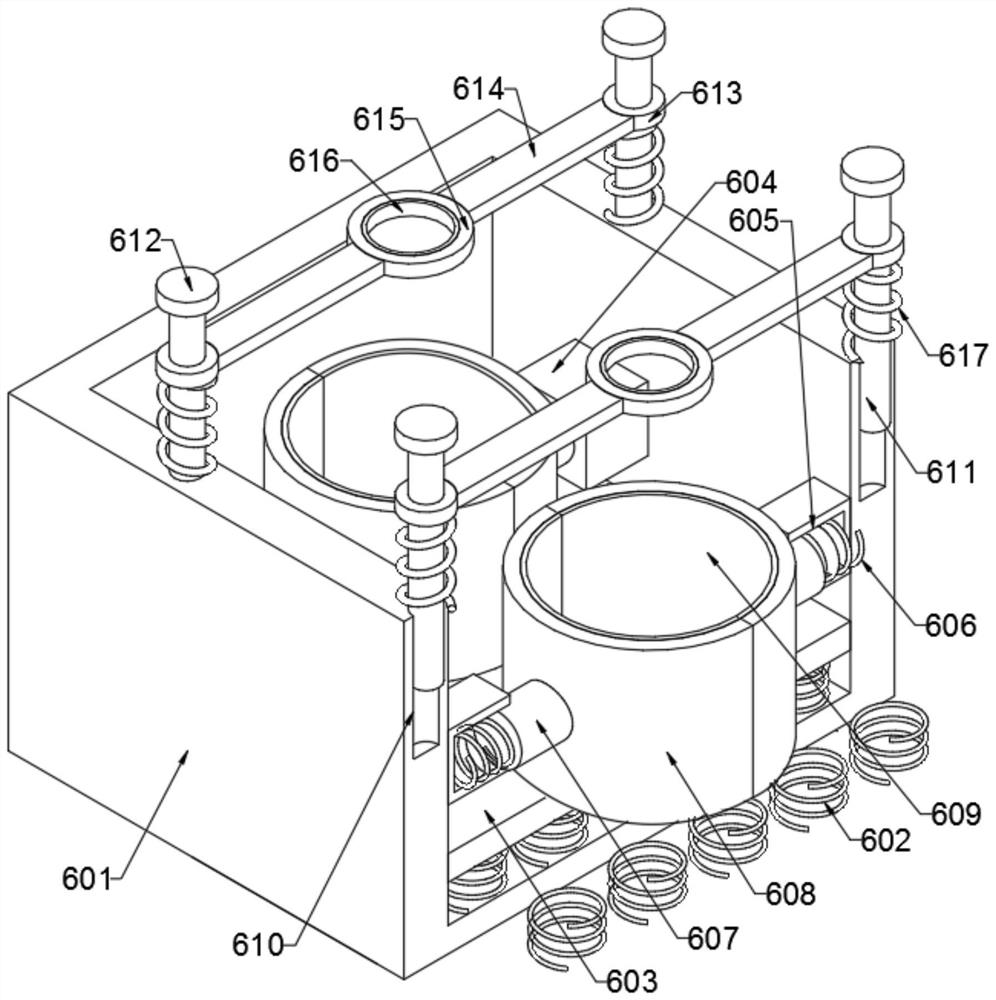

[0023] see Figures 1 to 2 , in the embodiment of the present invention, an auxiliary loading device used in the production of ceramic wine bottles, including a transfer table 1, a transport mechanism 6 and a transfer mechanism 7, the transfer table 1 is provided with a through slot 2, and the through slot 2 The transmission plate 3 is slidably connected. The front and rear ends of the transmission plate 3 are provided with a number of first limit blocks 4 . Position rod 5, the upper end of the first limit block 4 is provided with a transport mechanism 6, and the lower end of the transfer table 1 is provided with a transport mechanism 7, the transport mechanism 6 is fixed by a box 601, a first spring 602, a buffer plate 603, Block 604, groove 605, second spring 606, connecting rod 607, splint 608, first protective pad 609, positioning groove 610, sliding rod 611, limit plate 612, connecting ring 613, connecting plate 614, limit ring 615 , a second protective pad 616 and a thi...

Embodiment 2

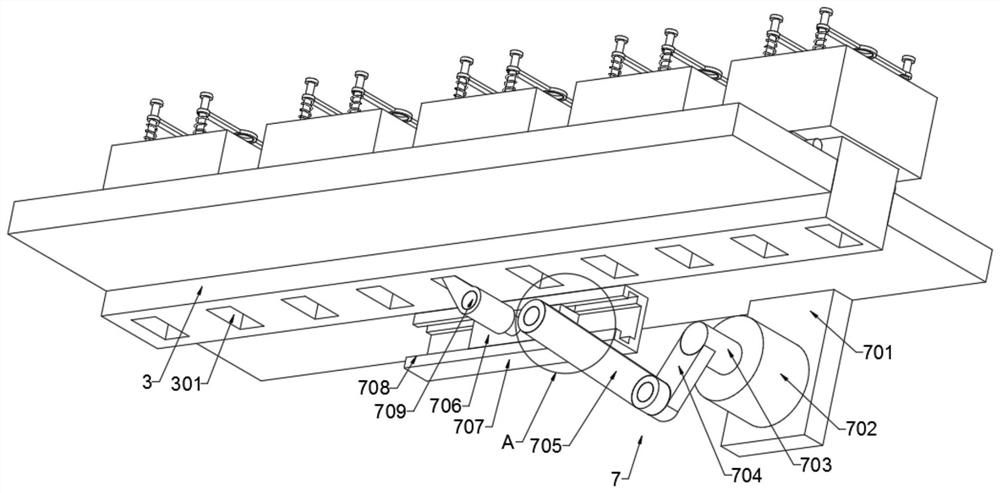

[0025] see Figures 3 to 4In the embodiment of the present invention, the transmission mechanism 7 consists of a fixed plate 701, a motor 702, a rotating shaft 703, a fixed rod 704, a movable rod 705, a slider 706, a connection block 707, a first limit slot 708, a push block 709, The second limit block 710 and the second limit slot 711 are formed. The upper end of the fixing plate 701 is fixedly connected to the conveying table 1 , the front end of the fixing plate 701 is provided with a motor 702 , and the front end of the motor 702 is provided with a rotating shaft 703 . A fixed rod 704 is provided, and the fixed rod 704 is movably connected to a movable rod 705, and the other end of the movable rod 705 is movably connected to a sliding block 706. The sliding block 706 is provided with a connecting block 707, and the upper end of the connecting block 707 is fixedly connected to the transfer table 1 , and the front end of the connecting block 707 is provided with a first limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com