Mechanical acceleration settling tank

A kind of clarification and mechanical technology, applied in mixers, mixer accessories, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor water quality, short mixing time, poor clarification effect, etc., to improve the clarification effect, The effect of increasing residence time and improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be noted that, on the premise of no conflict, the embodiments or technical features described below can be combined arbitrarily to form new embodiments. .

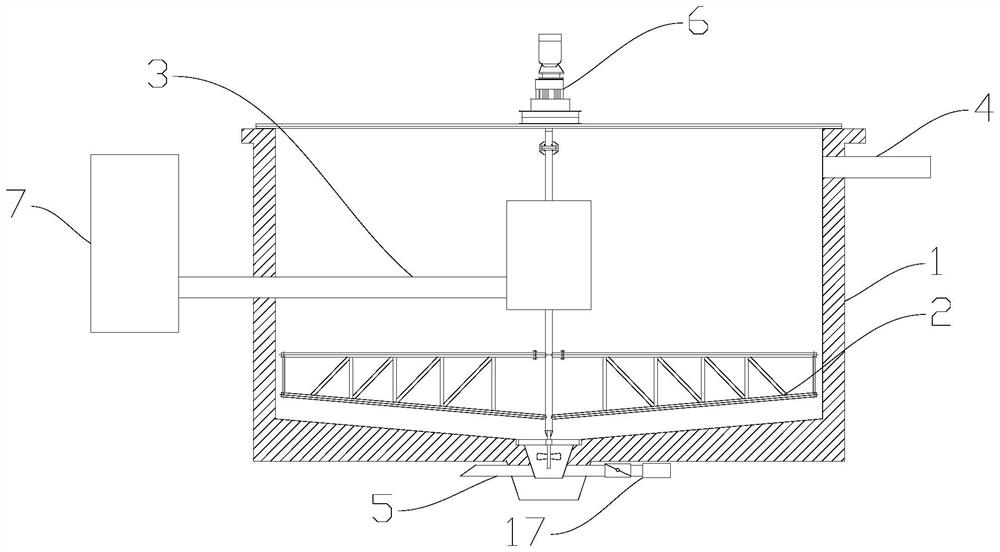

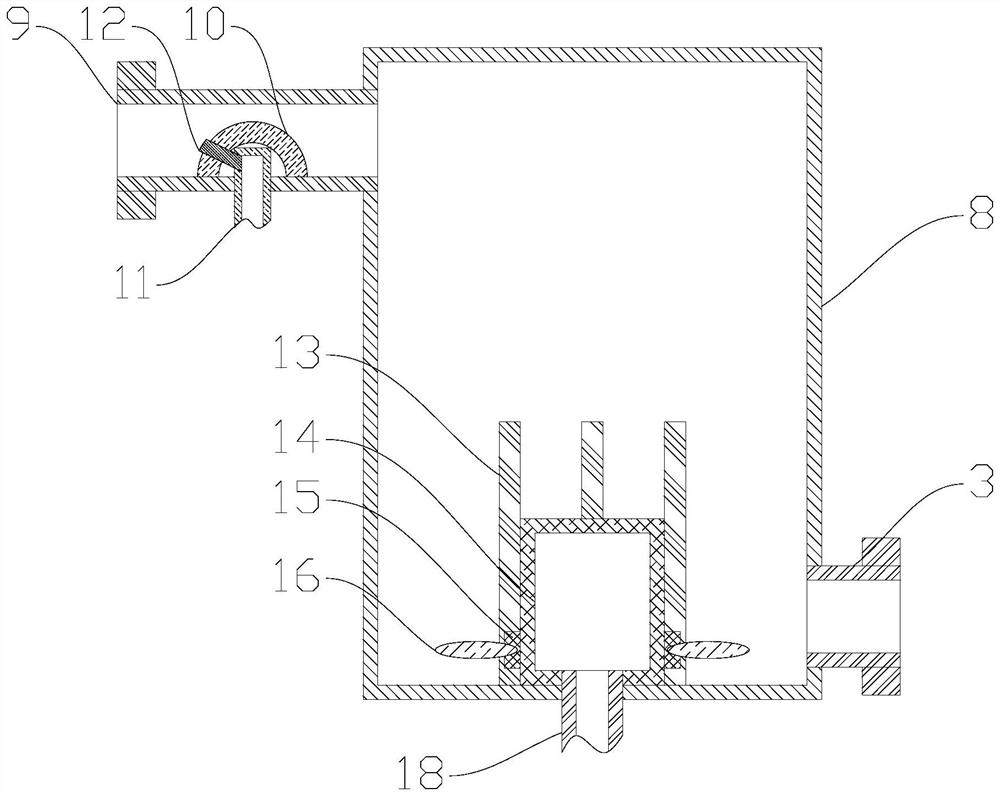

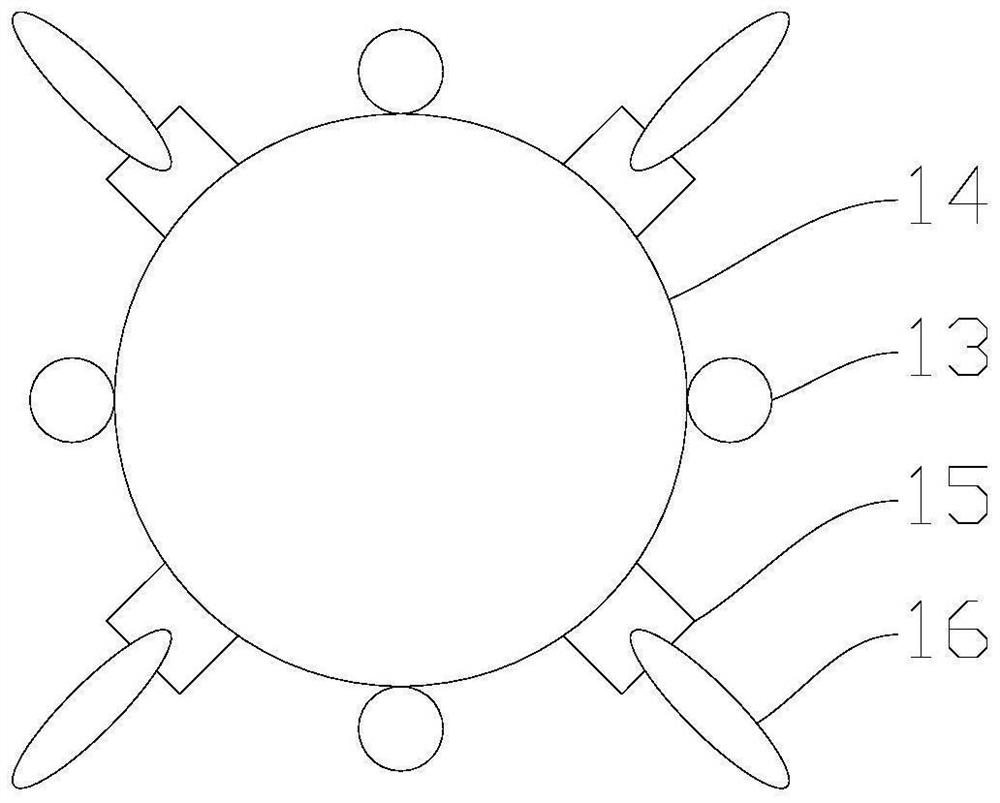

[0020] like Figure 1-3 As shown in the figure, the mechanically accelerated sedimentation tank includes a pool body 1, and the pool body 1 is provided with a stirring mechanism 2, a water inlet pipe 3, a water outlet pipe 4 and a sewage pipe 5, and the stirring mechanism 2 is driven by a motor 6, and the The front part of the water inlet pipe 3 is provided with a medicine mixing device 7, and the medicine mixing device 7 includes a medicine mixing chamber 8. An input pipe 9 is arranged on the upper part of one side of the mixing chamber 8, and the water inlet pipe 3 is connected to the mixing chamber. the lower part of the other side of the medicine chamber 8;

[0021] A bowl-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com