Waterproof heat-insulation spliced large board structure and preparation method thereof

A thermal insulation board and panel structure technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of increasing secondary investment, easy cracking of slats, and complicated connection methods between insulation boards and substrates, and achieves an increase of two Small investment, excellent waterproof performance, strong and safe anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

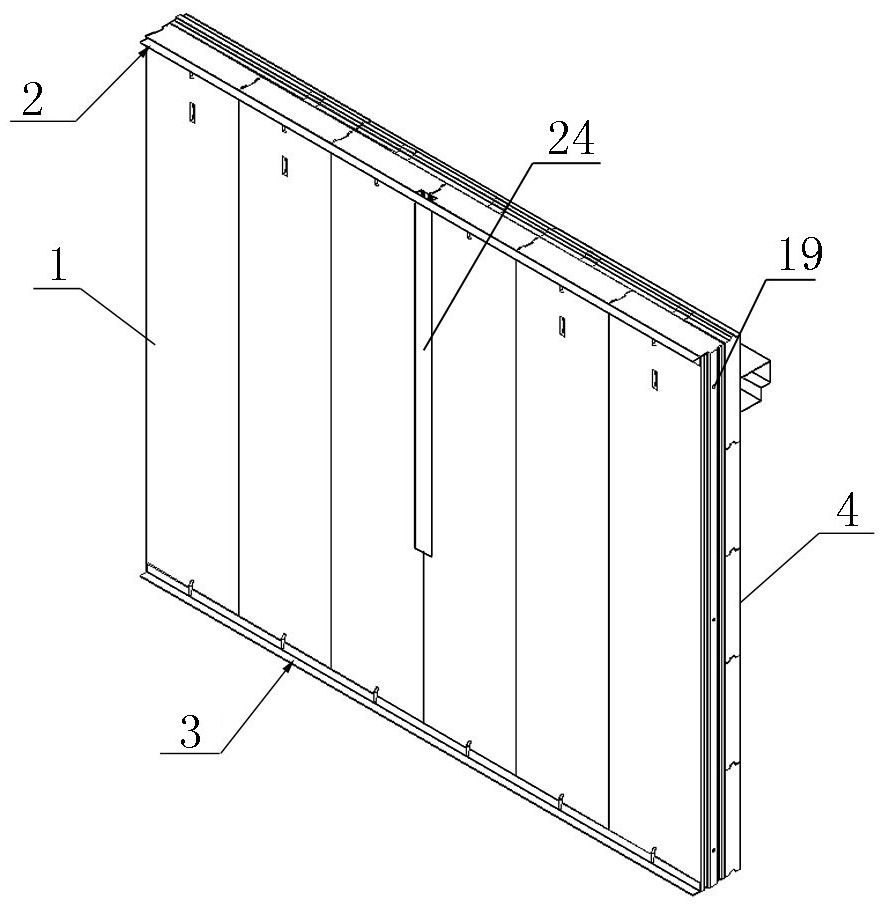

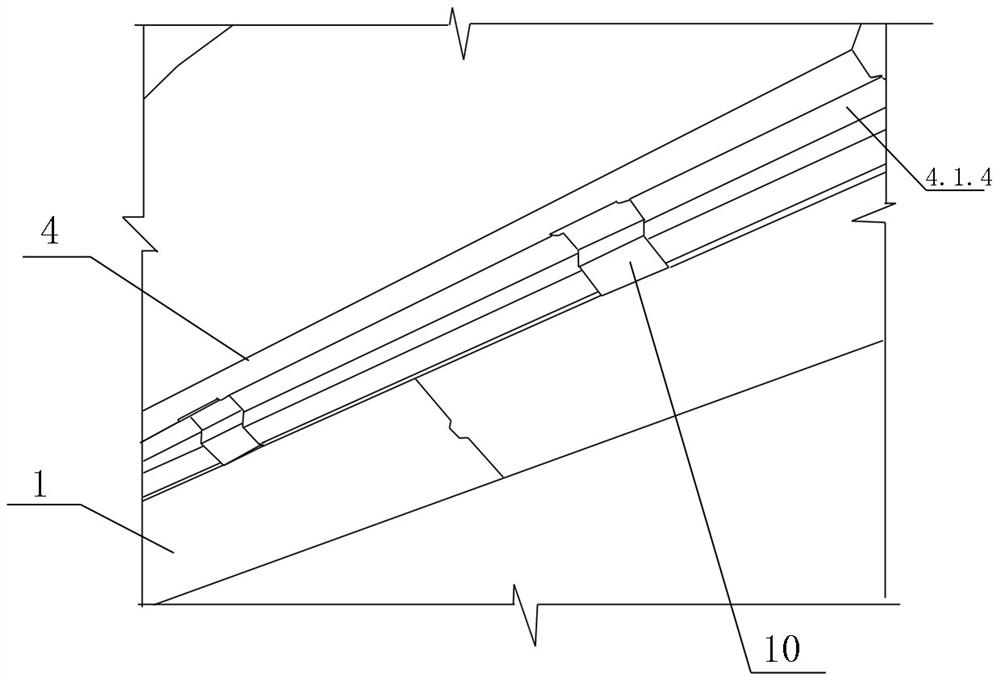

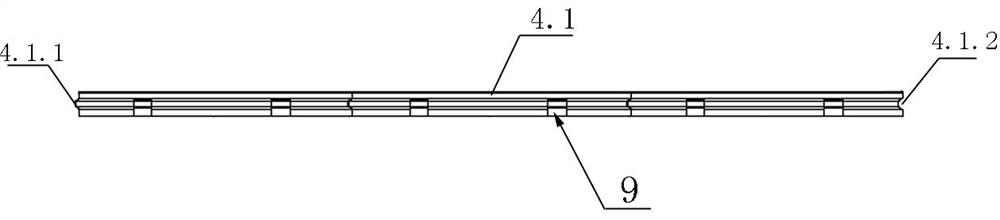

[0045] like Figure 1-12 As shown in the figure, this waterproof and thermal insulation assembled large plate structure includes a base plate 1, an upper connection assembly 2, a lower connection assembly 3 and a heat preservation plate 4; the base plate 1 includes a strip plate unit 1.1 and a sealing strip 1.2; the strip There is a set of shaped plate units 1.1, which are spliced and connected in the horizontal direction. Each strip-shaped plate unit 1.1 is made of autoclaved lightweight concrete; Slot 5, on the left side of the strip plate unit 1.1 and on both sides of the slot 5 are respectively provided with first embedding slots 6; on the right side of the strip plate unit 1.1, vertically extending There are protrusions 8, and second insert grooves 7 are respectively provided on the right side of the strip-shaped plate unit 1.1 and on both sides of the protrusions 8; tongue and groove connection; two sealing strips 1.2 are provided in each splicing seam of the strip-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com