Method for enhancing cooling effect of polylactic acid section and filter tip thereof

A polylactic acid and cigarette filter technology, which is applied in e-liquid filter elements, applications, food science, etc., can solve the problems of contact area and contact time to reduce temperature and high smoke temperature, and achieve the effect of balancing smoke and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

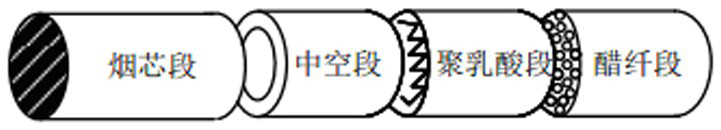

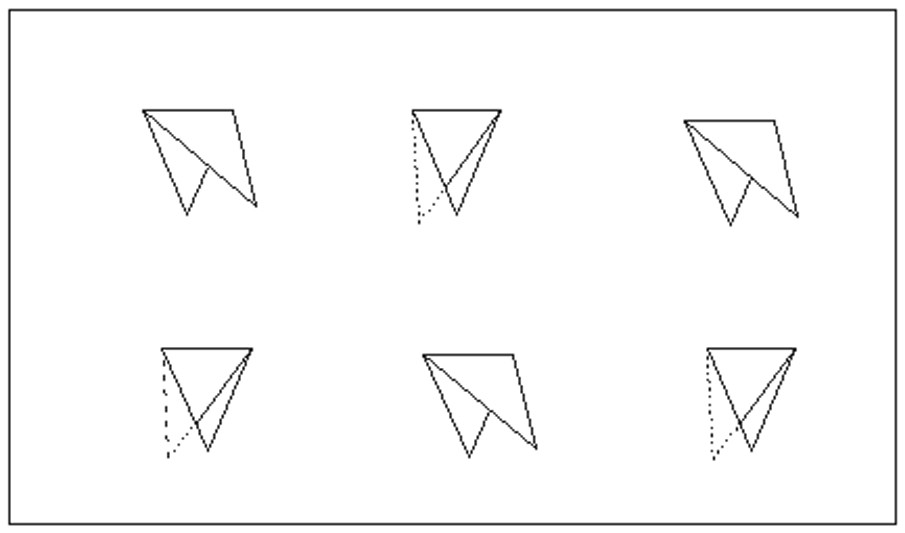

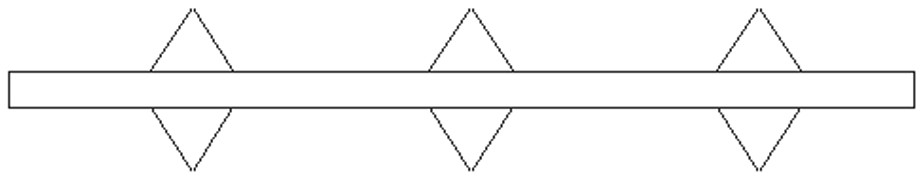

[0022] The present invention is further described below in conjunction with the accompanying drawings (embodiments):

[0023] like Figure 2-7 Shown: a method for enhancing the cooling effect of the polylactic acid section is to uniformly punch holes on the polylactic acid film constituting the polylactic acid film filter section of the cigarette filter, and ensure that the bottom edge of the hole is not cut off to form a connection with the film body and The everted fin film protrudes from both sides of the film body in a staggered manner, so that the flue gas during suction can circle and detour and fully contact the polylactic acid film for heat exchange, so as to improve the cooling effect of the polylactic acid section.

[0024] The angle between the fin film and the film body is 30°-45°; the height of the fin film above the film body is less than or equal to the distance between adjacent films after the polylactic acid film is rolled into a bundle.

[0025] The opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com