Device and method for inhibiting flying dust in construction process of building engineering

A technology of construction engineering and installation box, applied in the field of dust suppression in construction, can solve the problems of inconvenient automatic all-round spraying, affecting the effect of spraying and dust reduction, and reducing the service life of nozzles, so as to save the need for regular cleaning or replacement and avoid dust reduction. Not in place, the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

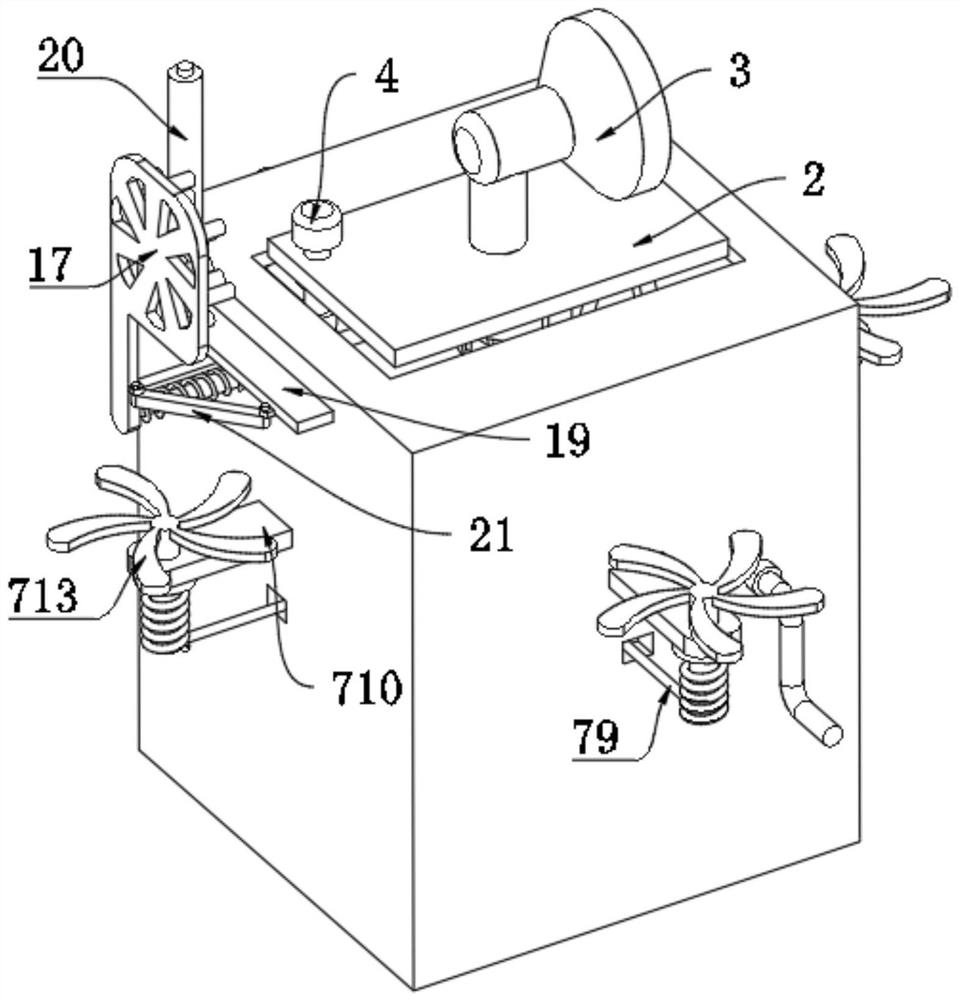

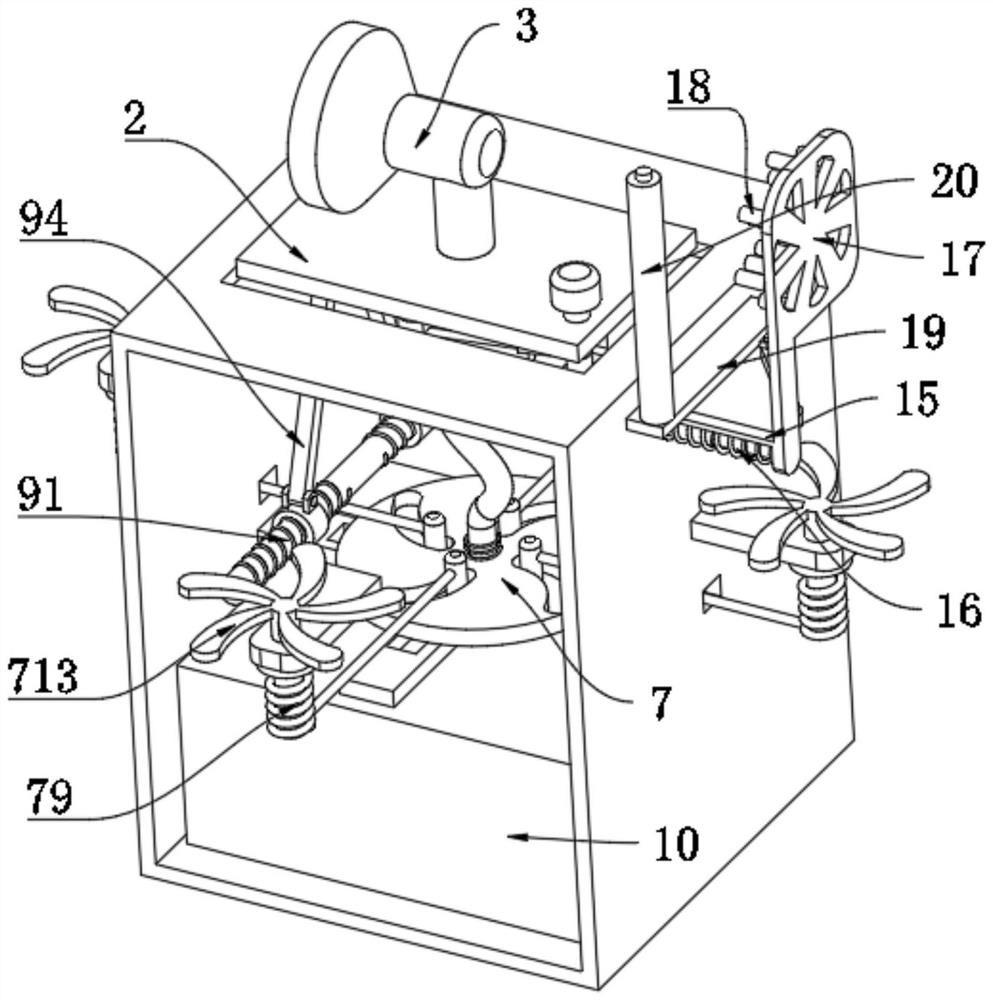

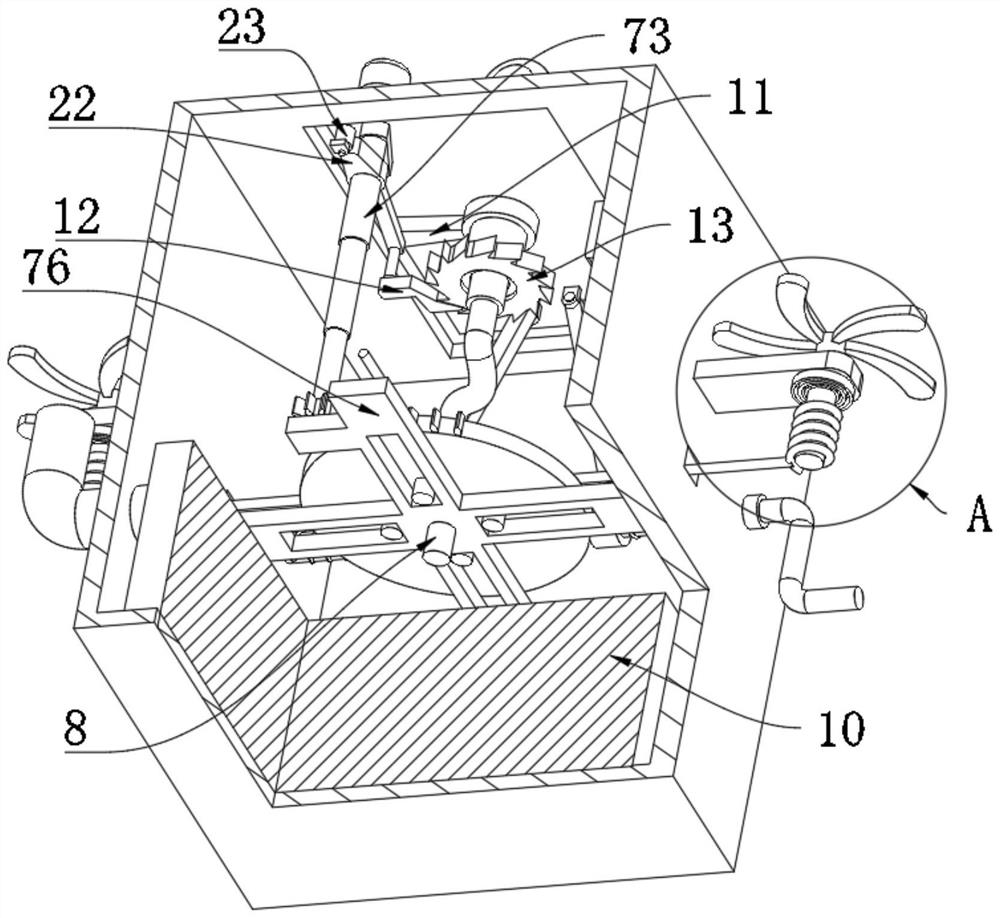

[0043] see figure 1 to and image 3 and Figure 5 , including the installation box 1, the inner cavity wall of the installation box 1 is slidably connected to the support plate 2 through the sliding groove and the slider, the upper end surface of the support plate 2 is rotatably connected with the spray head 3, and the upper end surface of the support plate 2 is fixedly connected with a small motor 4 , the output shaft of the small motor 4 penetrates the lower end surface of the support plate 2 and is fixedly connected with a crank 5, the inner cavity wall of the installation box 1 is installed with a diffusion mechanism 7, the inner cavity wall of the installation box 1 is installed with a lifting mechanism 9, and the cavity wall of the installation box 1 is installed with a lifting mechanism 9. The bottom is fixedly connected with a water tank 10, and the inner cavity wall of the water tank 10 is connected with a water pipe 8 through a water pump. A ratchet wheel 13 is fix...

Embodiment 2

[0046] see figure 1 and figure 2 , the right side wall of the installation box 1 is slidably connected with the vertical plate 17 through the sliding rod 15, the inner side wall of the vertical plate 17 is fixedly connected with the cleaning head 18, the upper end surface of the sliding rod 15 is rotatably connected with the wheel 23, the right side of the installation box 1 A spring telescopic rod 16 is fixedly connected to the side wall, and the right end of the spring telescopic rod 16 is fixedly connected to the lower end surface of the vertical plate 17 .

[0047] When working, through the cooperation of the sliding rod 15, the spring telescopic rod 16, the vertical plate 17, the cleaning head 18, the cam 22 and the runner 23, when the small motor 4 rotates, the cam 22 will also be driven to rotate. When the cam 22 rotates to the right When the rotating wheel 23 slides to the right, the vertical plate 17 slides to the right through the sliding rod 15 and stretches the s...

Embodiment 3

[0049] see figure 1 and figure 2 , the right side wall of the installation box 1 is slidably connected with a sliding plate 19, the upper end face of the sliding plate 19 is rotatably connected with an installation shaft, the outer wall of the installation shaft is inserted with a sponge roller 20, and the right side wall of the sliding plate 19 is rotatably connected with a connecting rod 21, connecting One end of the rod 21 away from the sliding plate 19 is rotatably connected with the side wall of the vertical plate 17 .

[0050] During operation, through the cooperation of the sliding plate 19, the installation shaft, the sponge roller 20 and the connecting rod 21, when the vertical plate 17 slides inward, it will rotate by squeezing the connecting rod 21, thereby driving the sliding plate 19 to slide backward, so that the upper The sponge roller 20 slides backward and wipes the cleaning head 18 , which can scrape off the dust and sundries on the cleaning head 18 , keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com