Drilling and edging integrated equipment for intelligent furniture manufacturing

An intelligent furniture and edging technology, which is used in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, manufacturing tools, etc. Problems such as roughness at the hole, to achieve the effect of convenient adjustment, convenient installation and operation, and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

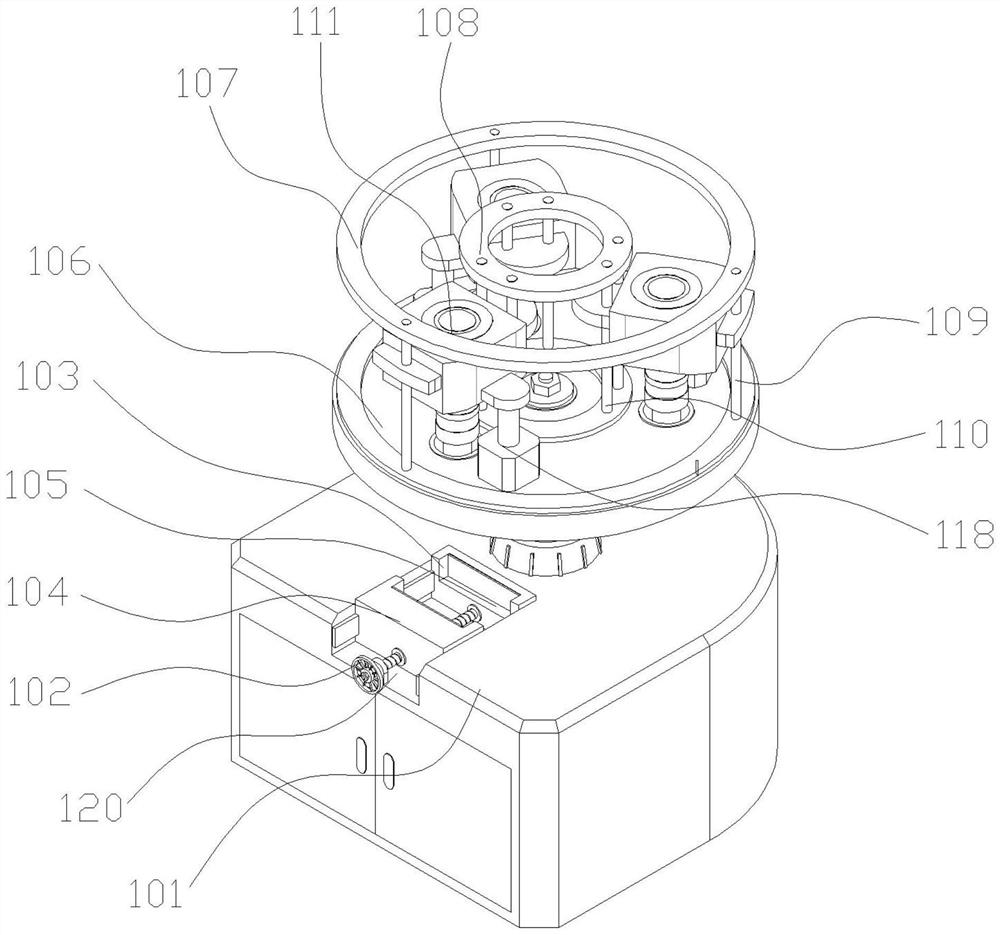

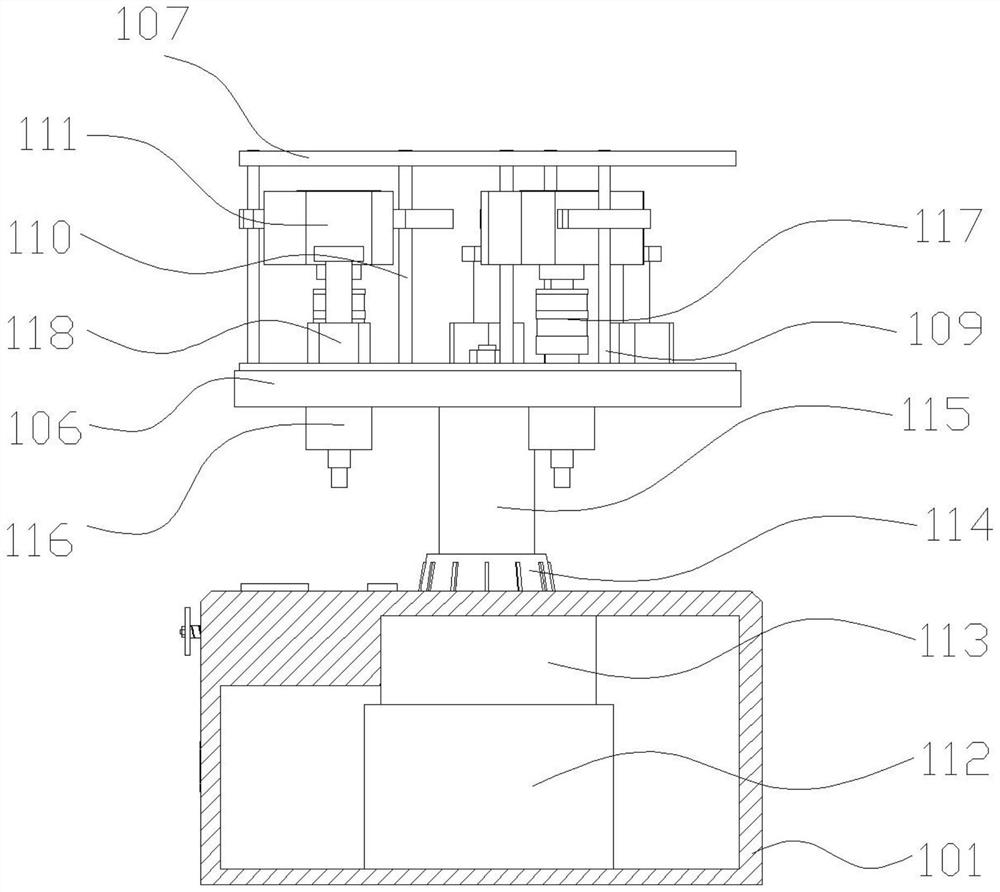

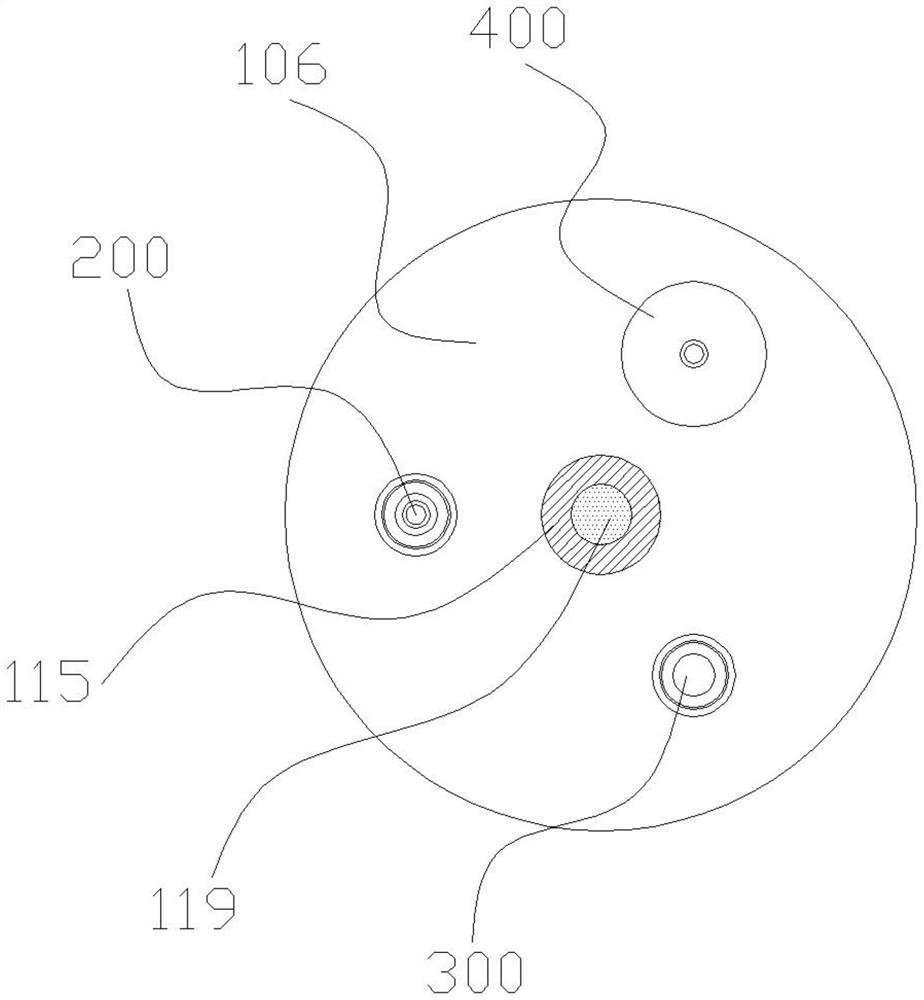

[0030] Below in conjunction with specific embodiment and description accompanying drawing, the present invention will be further elaborated and described:

[0031] see Figure 1-Figure 8 As shown, an integrated drilling and edging equipment for intelligent furniture manufacturing provided by the present invention includes an installation table 101, a chute 102 is opened on the installation table 101, and a fixed splint 103 is fixedly installed in the chute 102, and the sliding A movable splint 104 is slidably installed in the groove 102 , a screw 120 is rotatably arranged on the fixed splint 103 , and the screw 120 cooperates with the movable splint 104 . A reducer 113 is installed, a rotating shaft 119 is rotatably installed on the upper side of the mounting table 101, the second driving motor 112 is driven and connected to a rotating shaft 119 through the reducer 113, the rotating shaft 119 is fixedly connected with a rotating disk 106, and the rotating disk 106 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com