Driving mechanism for mountain double-rail conveyor

A technology of driving mechanism and conveyor, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inability to transport and use, weak climbing ability, etc., and achieve the effect of strong load capacity and strong climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

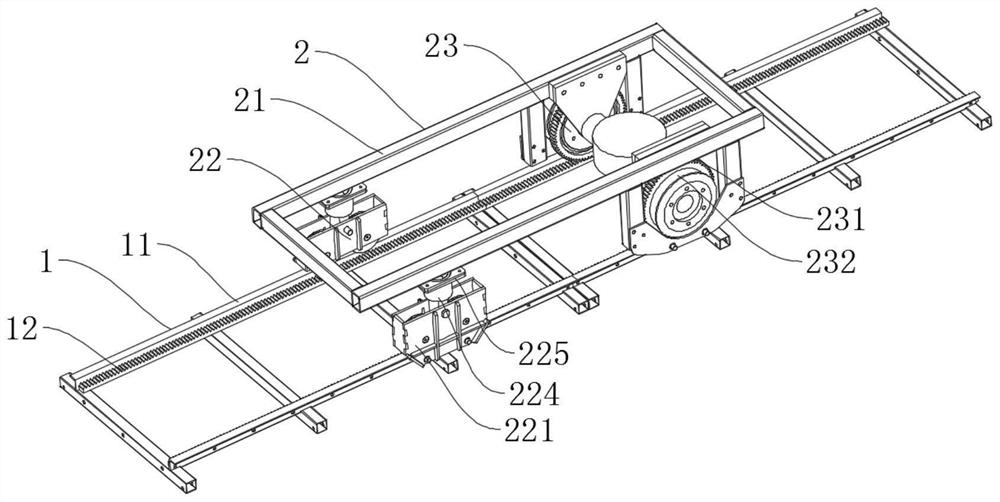

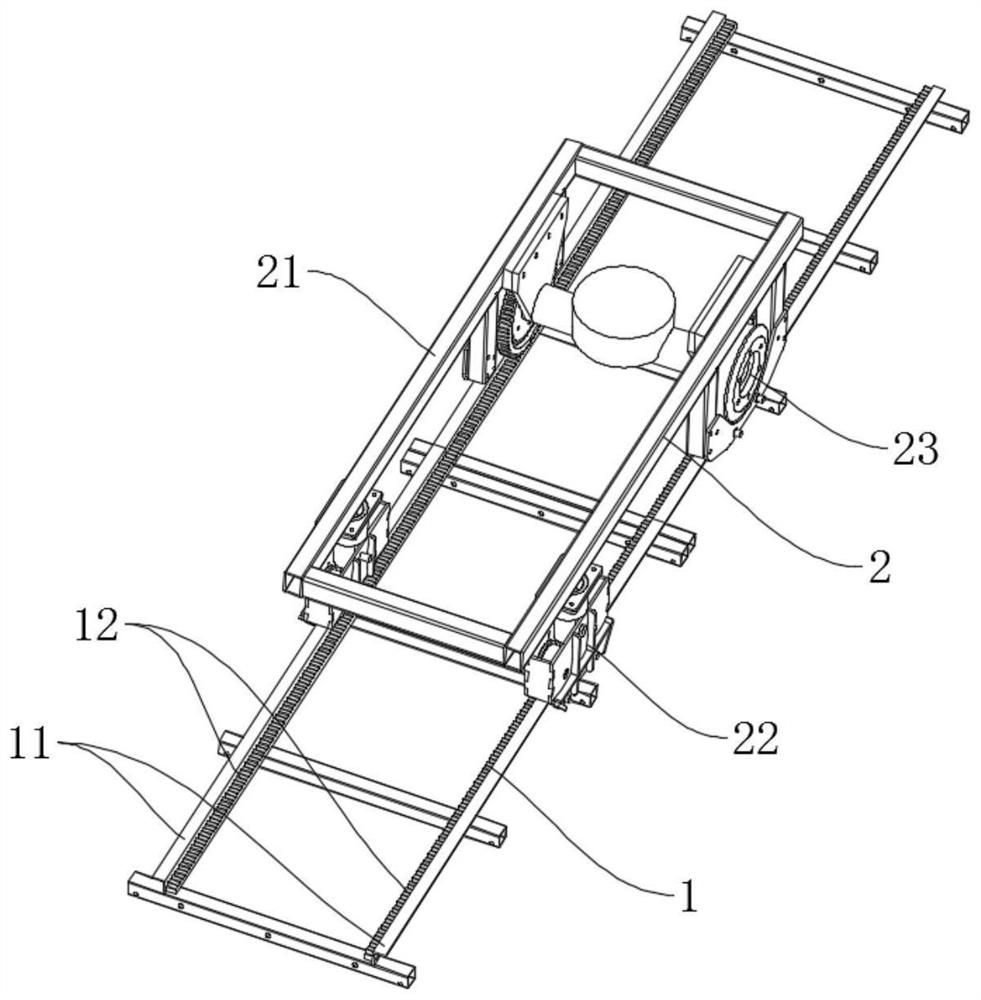

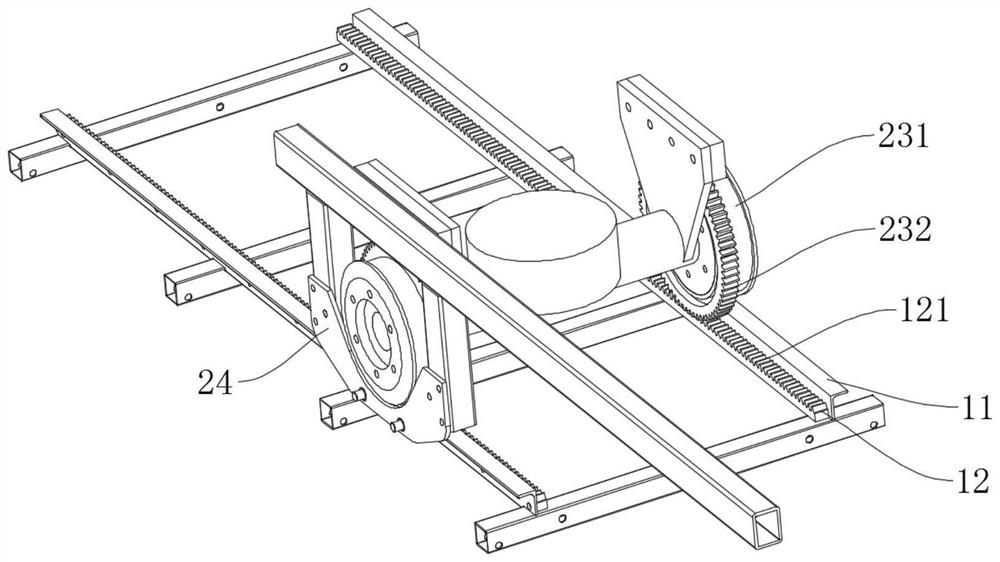

[0028] according to Figure 1 to Figure 5 As shown, a driving mechanism for a mountain double-track transporter includes: a double-track system 1 and a transport machine frame 2; , the meshing drive track 12 is provided with an meshing portion 121; the transport machine frame 2 includes: a vehicle frame 21, a supporting wheel 22 and a driving wheel 23, the driving wheel 23 is connected with the driving shaft, and the supporting wheel 22 and the driving wheel 23 are installed below the frame 21 , the driving wheel 23 includes a support part 231 and a meshing drive part 232 , the support part 231 is connected with the guide rail 11 , and the meshing drive part 232 is meshed and connected with the meshing drive rail 12 through the meshing part 121 . The engaging drive rails 12 are provided on the inner sides of the two guide rails 11 . The meshing part 121 has a rack structure, and the meshing driving part 231 has a gear structure.

[0029] according to image 3 As shown, the ...

Embodiment 2

[0033] according to Image 6 As shown, the difference from the above-mentioned Embodiment 1 is that the meshing portion 121 is a corrugated steel plate structure, and the meshing driving portion 231 is a sharp-edged disc structure. .

Embodiment 3

[0035] according to Figure 7 As shown, the difference from the above-mentioned Embodiment 1 is that the meshing part 121 is a perforated steel pipe structure, and the meshing driving part 231 is a boss disc structure, and the boss disc structure includes, tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com