Mine vertical shaft composite shaft wall structure and construction method thereof

A vertical structure and shaft wall technology, applied in shaft equipment, mining equipment, earthwork drilling and mining, etc., can solve the problem of poor adhesion of outer shaft wall concrete, poor coordination of composite shaft wall structure, slow construction progress, etc. problems, to achieve the effect of simple construction, good stress effect, and enhanced pressure relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. For the convenience of description, the words "up", "down", "left" and "right" appear in the following text, which only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

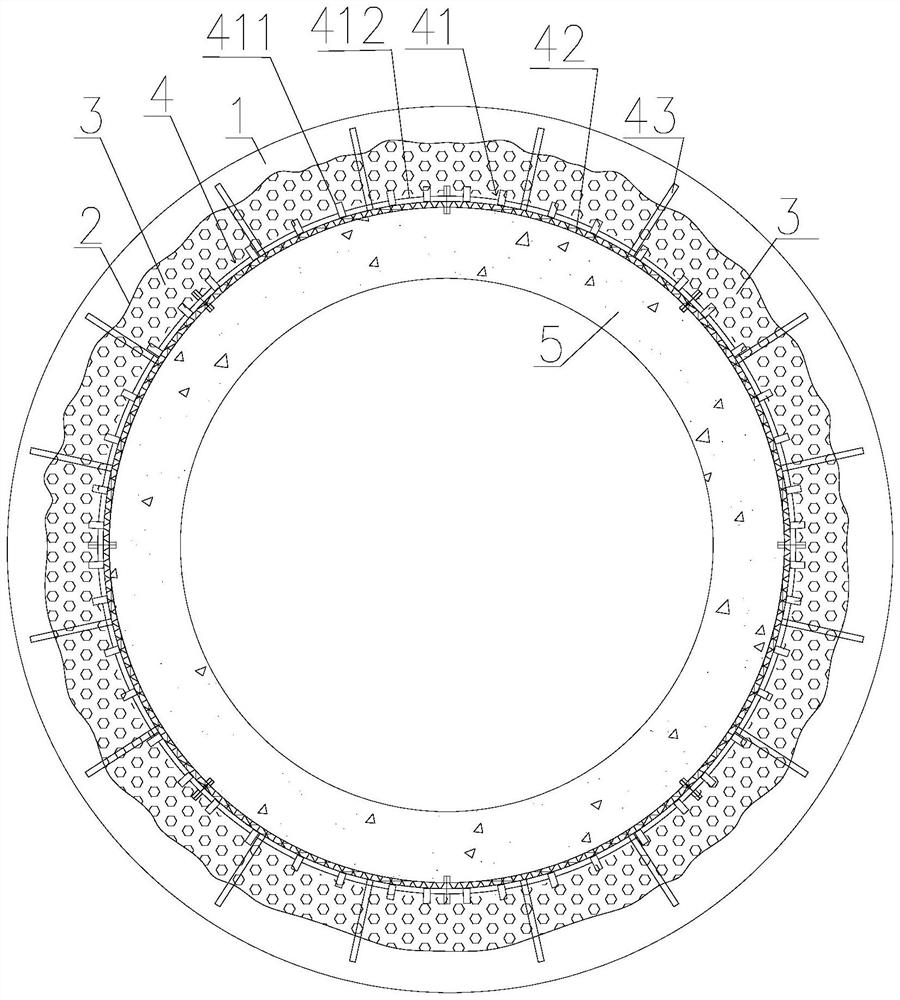

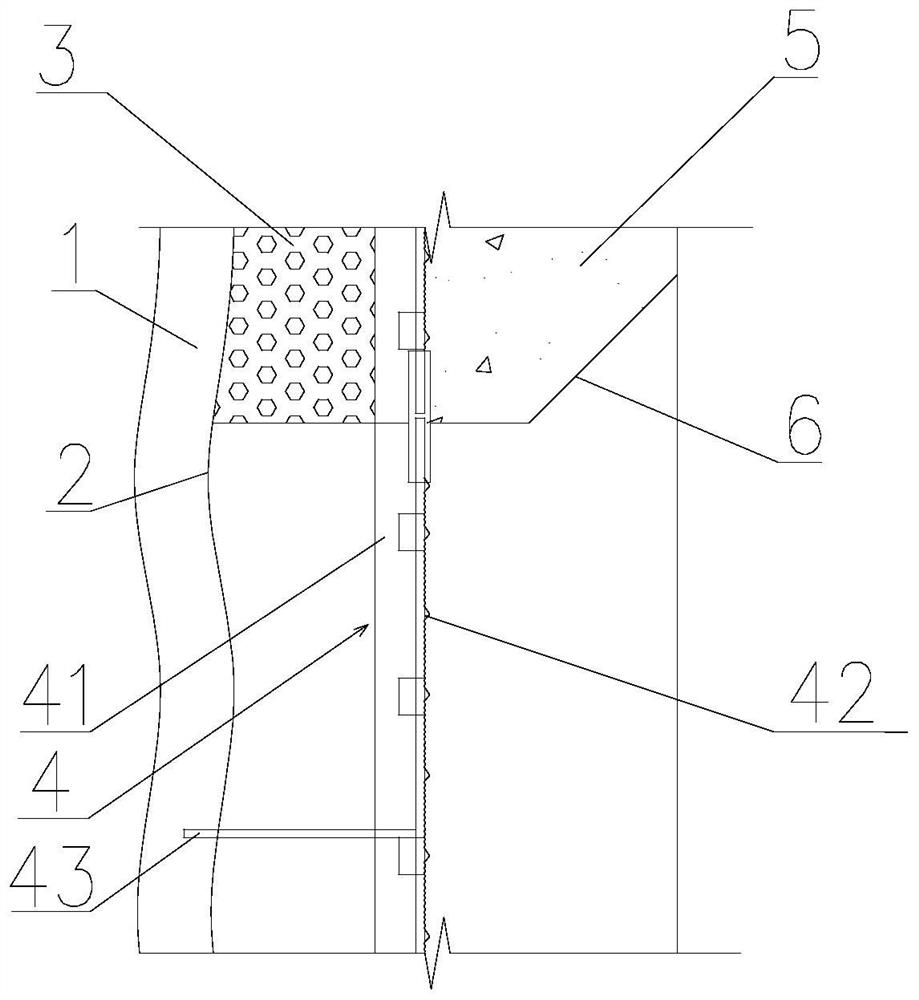

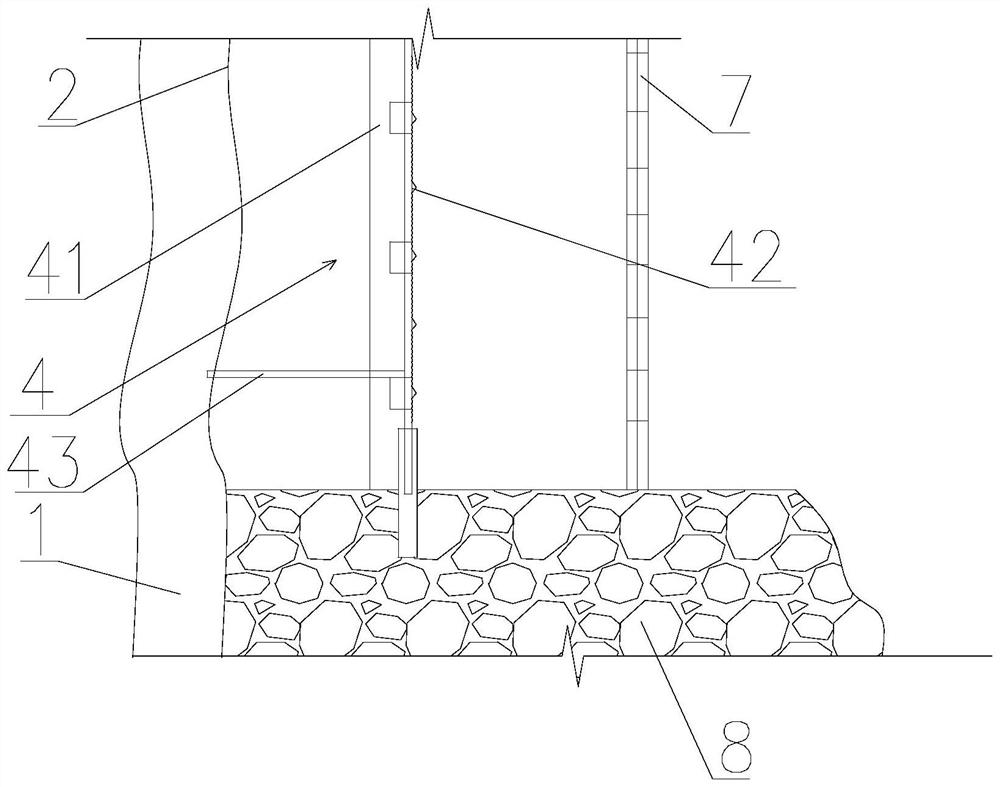

[0033] like figure 1 As shown, a composite shaft wall structure of a mine shaft includes an outer shaft wall 3 , an inner shaft wall 5 and a dismantling-free formwork layer 4 , and the dismantling-free formwork layer 4 includes a frame 41 and a formwork mesh 42 . The cross section of the frame 41 is a closed annular structure, one side of which is adjacent to the inner side surface of the outer shaft wall 3 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com