A method for regulating monoammonium phosphate supernutrients by utilizing phosphate rock flotation tailings

A technology of monoammonium phosphate and flotation tailings, which is applied in ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problem of long process flow of calcium magnesium phosphate fertilizer production equipment, difficult environmental pollution control, and lack of universality. Applicability and other issues, to achieve the effect of significant appearance quality, improved appearance quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

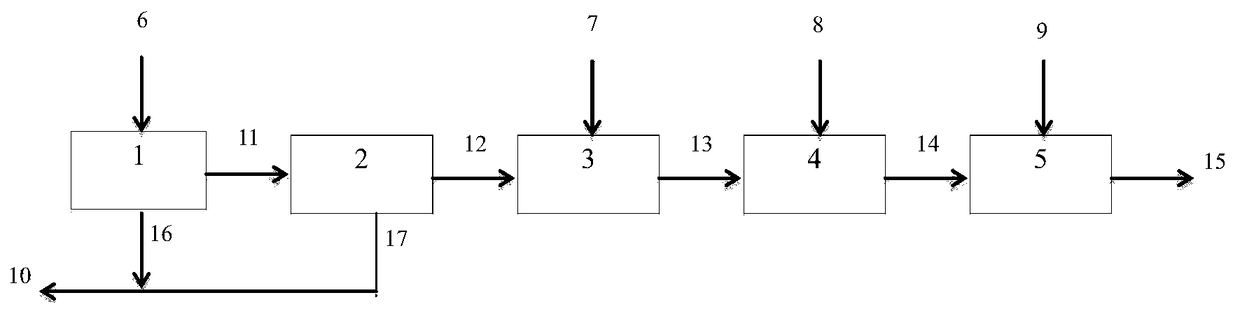

[0026] In this example, phosphate rock flotation tailings slurry is used as raw material, and qualified monoammonium phosphate slurry is obtained through tailings slurry thickening and filtration, phosphoric acid leaching, slurry neutralization, and nitrogen supplementation, and the adjustment of monoammonium phosphate supernutrients is realized. Its production process is shown in the appendix figure 1 .

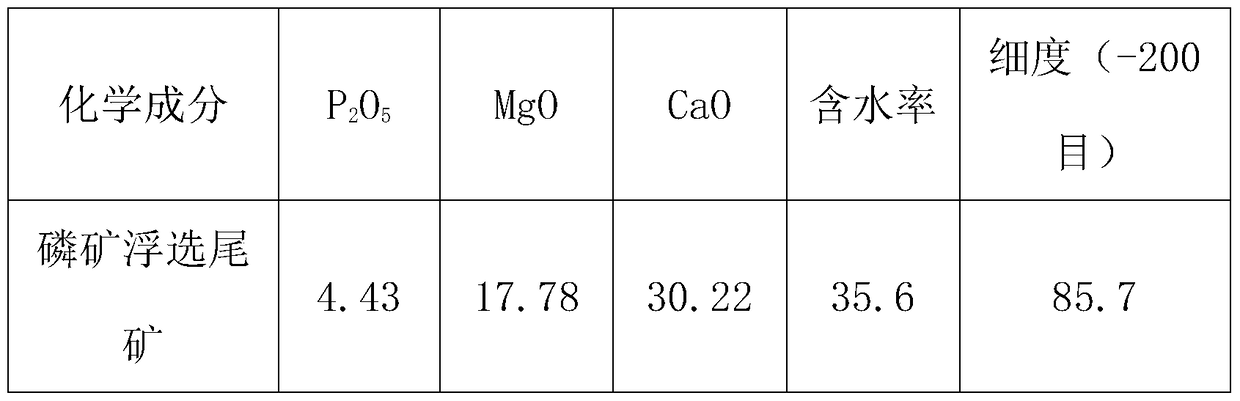

[0027] (1) The chemical composition (mass percentage %) of the phosphate rock flotation tailings raw material used in this example

[0028]

[0029] (2) The technological process and operation steps of this example are as follows:

[0030] The phosphate ore flotation tailings 6 are sent to the high-efficiency thickener thickener 1, and the bottom dense phase 11 is sent to the filter 2 for filtration and separated into filter cake 12 and filtrate 17, and the filtrate 17 and the upper clear liquid 16 are combined to form tailings backwater 10 Return to Phosphate Float

...

Embodiment 2

[0037] (1) The chemical composition (mass percentage %) of the phosphate rock flotation tailings raw material used in this example

[0038]

[0039] (2) Send the phosphate ore flotation tailings 6 to the high-efficiency thickener thickener 1, and the bottom dense phase 11 is sent to the filter 2 for filtration and separated into filter cake 12 and filtrate 17, and the filtrate 17 and the supernatant liquid 16 merge to form tailings Backwater 10 returns to the phosphate rock flotation unit; metered filter cake 12 and 25.02%P 2 o 5 Dilute phosphoric acid 7 is placed in the phosphoric acid leaching tank 3, the reaction temperature is controlled at 80-85°C, the stirring speed is 400r / min, and the reaction time is 70min, and the mixed slurry 13 is obtained after the phosphoric acid leaching reaction is sufficient; the measured mixed slurry 13 and ammonia 8 in the neutralization tank 4 until the pH value reaches 4.5-4.7 to obtain a neutralized slurry 14, and control the neutrali...

Embodiment 3

[0045] (1) The chemical composition (mass percentage %) of the phosphate rock flotation tailings raw material used in this example

[0046]

[0047] (2) The technological process and operation steps of this example are as follows:

[0048] The phosphate ore flotation tailings 6 are sent to the high-efficiency thickener thickener 1, and the bottom dense phase 11 is sent to the filter 2 for filtration and separated into filter cake 12 and filtrate 17, and the filtrate 17 and the upper clear liquid 16 are combined to form tailings backwater 10 Back to phosphate rock flotation unit; metered filter cake 12 and 30.63% P 2 o 5 Dilute phosphoric acid 7 is placed in the phosphoric acid leaching tank 3, the reaction temperature is controlled at 85-90°C, the stirring speed is 500r / min, and the reaction time is 60min, and the mixed slurry 13 is obtained after the phosphoric acid leaching reaction is sufficient; the measured mixed slurry 13 and ammonia 8 in the neutralization tank 4 u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com