High-efficiency composite bactericide for circulating water system and preparation method thereof

A compound fungicide and high-efficiency technology, applied in the directions of fungicides, botanical equipment and methods, biocides, etc., can solve the problems of incapable of sharing chlorophenol biocides, reducing the biocidal effect of quaternary ammonium salts, and increasing water treatment costs, etc. To achieve the effect of not easy drug resistance, good synergism, and fast killing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The high-efficiency composite bactericide of the present invention has the following ingredients by weight percentage: 15% glutaraldehyde, 42% quaternary phosphonium salt, 11% isothiazolinone, 24% deionized water, and 8% dithiocyanomethane. Wherein the quaternary phosphonium salt is tetrakis hydroxymethyl phosphonium sulfate and tetradecyl tributyl phosphonium chloride, the mass ratio of the two is 1.7:2

[0020] Its preparation method is carried out according to the following steps successively:

[0021] (1) Add glutaraldehyde and tetrakis hydroxymethyl phosphonium sulfate to the reaction kettle and stir for 5 minutes at normal temperature;

[0022] (2) in the mixed solution of tetradecyltributylphosphonium chloride and isothiazolinone step (1), stir for 10 minutes;

[0023] (3) Finally, add dithiocyanomethane and deionized water into the mixed solution obtained in step (2), and stir for 10 minutes to obtain the finished product.

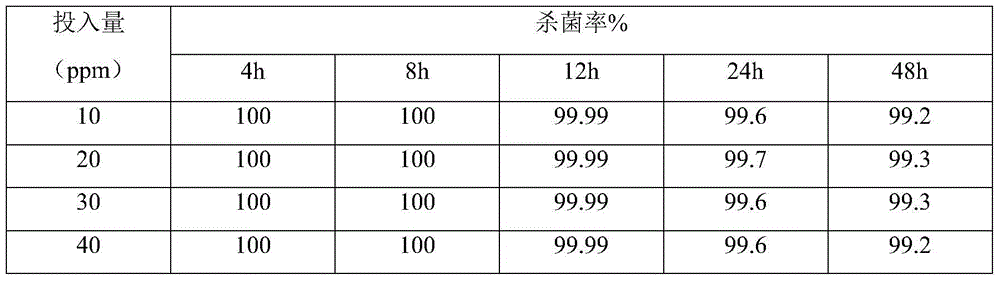

[0024] The use effect of the presen...

Embodiment 2

[0039] The high-efficiency composite bactericide of the present invention comprises the following ingredients by weight percentage: 16% glutaraldehyde, 44% quaternary phosphonium salt, 15% isothiazolinone, 20% deionized water and 5% dithiocyanomethane. Wherein the quaternary phosphonium salt is tetrakis hydroxymethyl phosphonium sulfate and tetradecyl tributyl phosphonium chloride, the mass ratio of the two is 1.7:2

[0040] Its preparation method is carried out according to the following steps successively:

[0041] (1) Add glutaraldehyde and tetrakis hydroxymethyl phosphonium sulfate to the reaction kettle and stir for 10 minutes at normal temperature;

[0042] (2) in the mixed solution of tetradecyltributylphosphonium chloride and isothiazolinone step (1), stir for 15 minutes;

[0043] (3) Finally, add dithiocyanomethane and deionized water into the mixed solution obtained in step (2), and stir for 15 minutes to obtain the finished product.

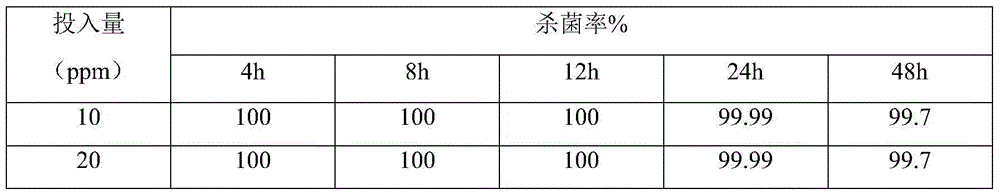

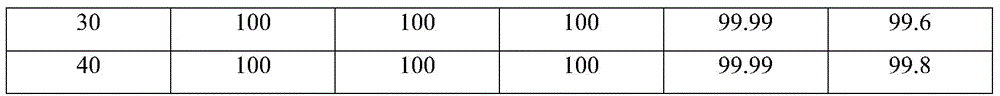

[0044] The use effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com