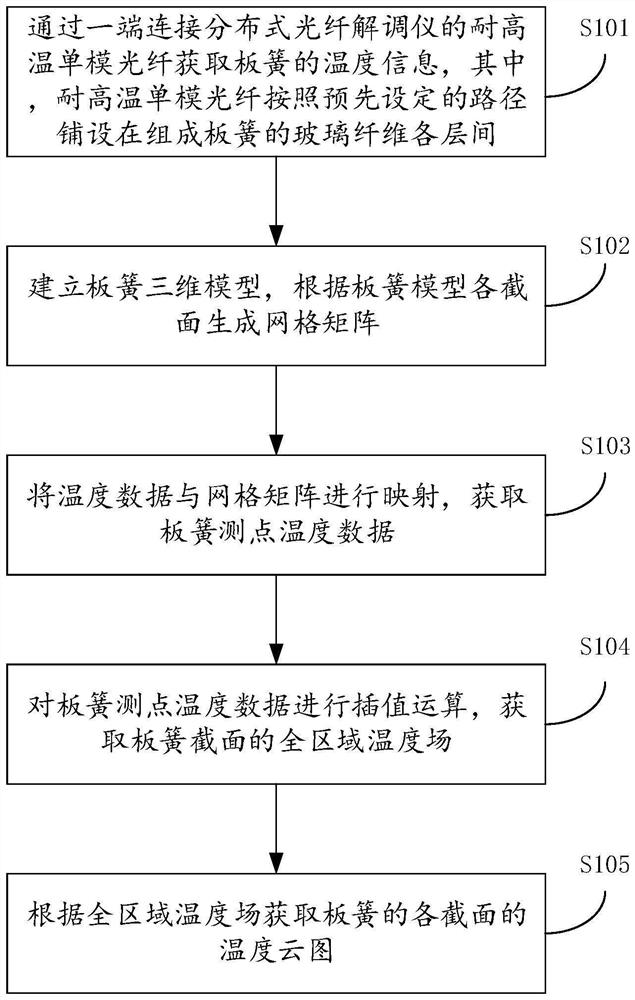

Distributed optical fiber embedded plate spring preparation temperature visual monitoring method and device

A technology of distributed optical fiber and leaf spring, which is applied in measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve the problems of mold modification and high cost, and achieve the effect of an intuitive temperature monitoring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] According to an embodiment of the present invention, a visual monitoring device for the preparation temperature of a distributed optical fiber embedded leaf spring is provided, Figure 5 It is a schematic diagram of a distributed optical fiber embedded leaf spring preparation temperature visual monitoring device according to an embodiment of the present invention, such as Figure 5 As shown, according to the embodiment of the present invention, the distributed optical fiber-embedded plate spring preparation temperature visualization monitoring device specifically includes:

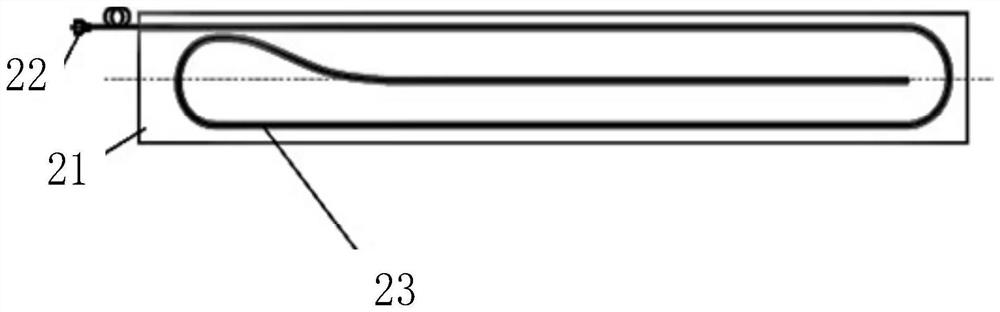

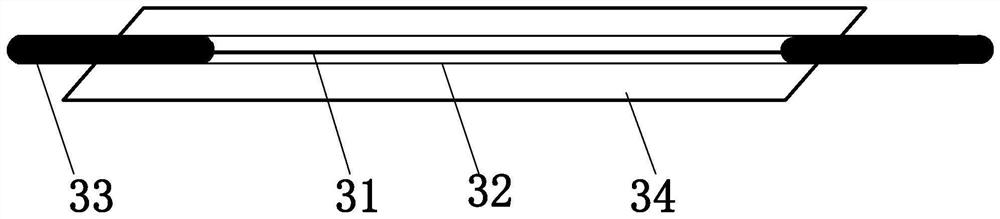

[0061] The temperature obtaining unit 50 obtains the temperature information of the leaf spring through a high-temperature-resistant single-mode optical fiber connected to the distributed optical fiber demodulator at one end, wherein the high-temperature-resistant single-mode optical fiber is laid on each layer of the glass fiber constituting the leaf spring according to a preset path between;

[0...

Embodiment 2

[0069] An electronic device according to an embodiment of the present invention includes:

[0070] processor; and,

[0071] A memory arranged to store computer-executable instructions which, when executed, cause the processor to perform the steps as described in the above-described method embodiments.

Embodiment 3

[0073]Embodiments of the present invention provide a storage medium for storing computer-executable instructions, where the computer-executable instructions, when executed, implement the steps described in the foregoing method embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com