Method and device for eliminating influence of hydrogen peroxide on COD (Chemical Oxygen Demand) determination

A hydrogen peroxide and scavenging agent technology, applied in the field of chemical analysis, can solve the problems affecting the accurate measurement of COD results and the loss of volatile organic compounds, and achieve the effects of avoiding the loss of volatile organic components, eliminating the impact, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

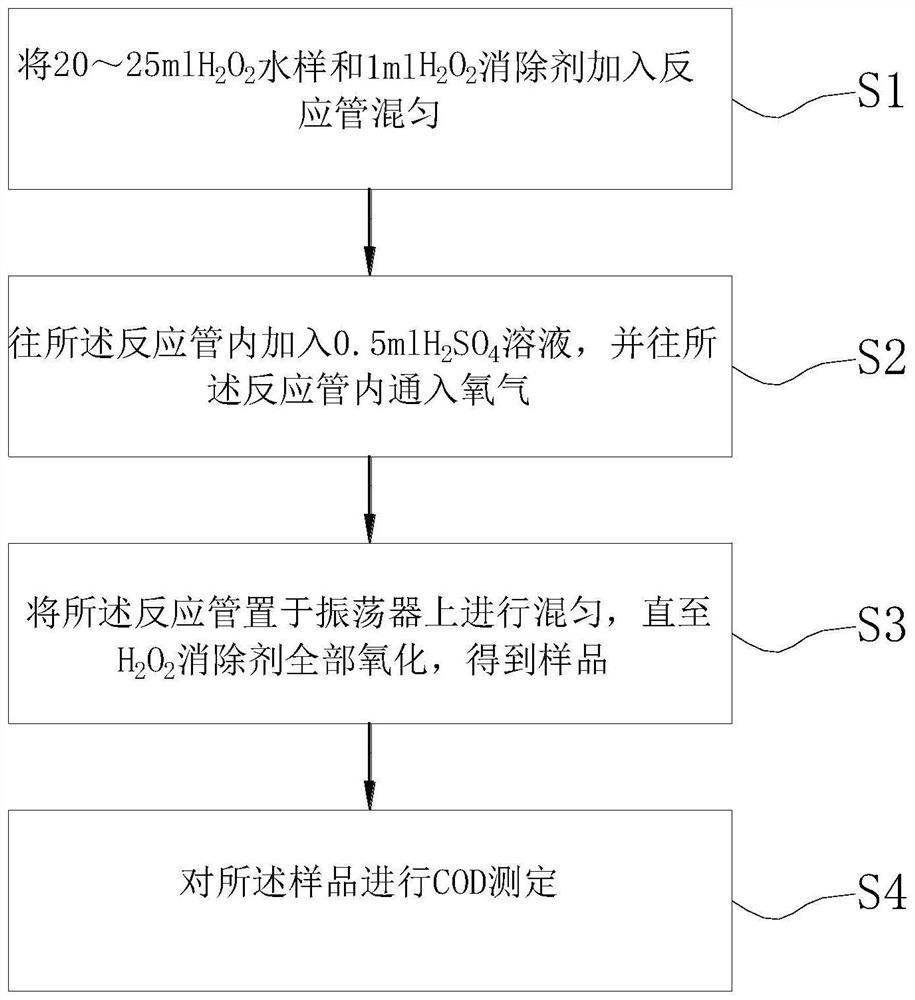

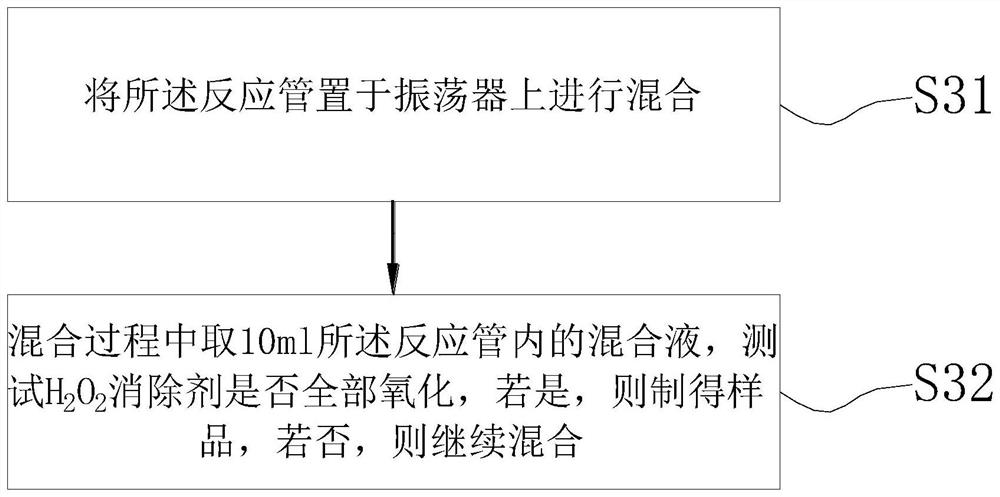

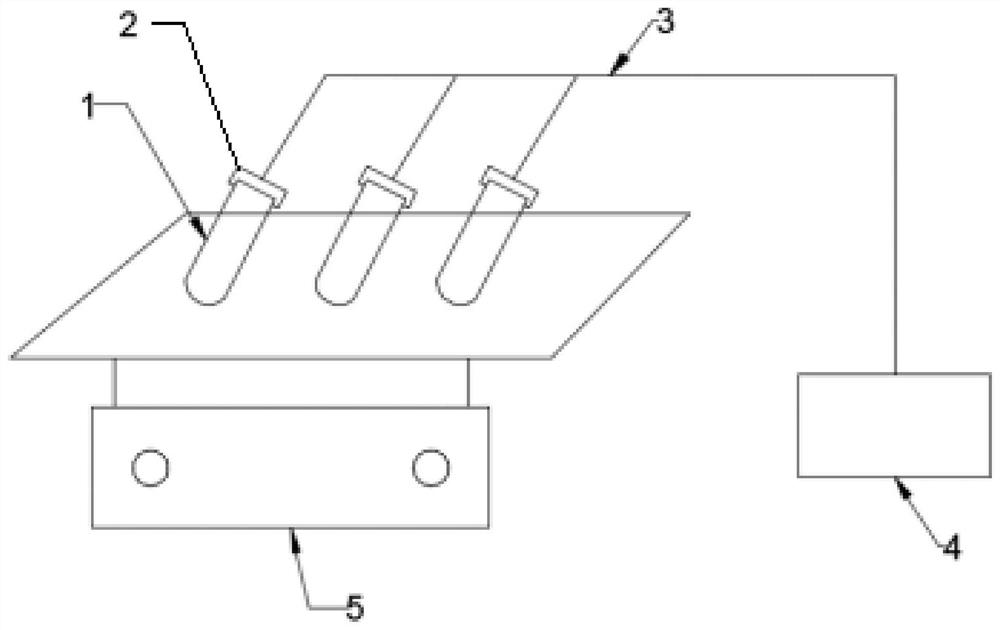

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the COD determination of artificial configuration containing H2O2 phenol solution;

[0043] Formulated to contain 80mg / L phenol and 400mg / L H 2 O 2 Solution, the measured value of COD is 367mg / L, of which 80mg / L phenol contributes 200mg / L COD. Take 20mLH 2 O 2 Add the water sample to reaction tube 1, then add 1 mL of 10% H 2 SO 4 solution, H 2 O 2Undetectable, but residual Na 2 SO 3 As a result, the COD value rose to 600 mg / L. Add 0.5mL (1+6)H to reaction tube 1 2 SO 4 solution, then pass oxygen; fix the reaction tube 1 on the shaker 5, shake at 200 rev / min for 30min, Na 2 SO 3 If it cannot be detected, the COD concentration of the re-tested water sample is 195mg / L, which is not much different from the COD of phenol solution of 200mg / L, and the difference is within the 5% error range of the COD determination method.

Embodiment 2

[0044] Example 2: COD determination of leather wastewater after Fenton treatment;

[0045] The COD concentration of the leather wastewater sample is 230mg / L (water sample after biological treatment), which is treated by Fenton oxidation. The reaction conditions are as follows: pH=4, H 2 O 2 Concentration 400mg / L, Fe 2 +Concentration 35mg / L, reaction time 2h, sample H after Fenton treatment 2 O 2 The concentration is 185mg / L, and the measured COD concentration is 223mg / L, after deducting 185mg / LH 2 O 2 Contribution of 75mg / L COD, the actual COD concentration of remaining organic matter in leather wastewater is 148mg / L. The samples after Fenton treatment were treated with the above method to eliminate H 2 O 2 Influence on COD determination: take 20mLH 2 O 2 Add water sample to reaction tube 1, then add 1 mL of 10% Na 2 SO 3 solution; add 0.5mL (1+6)H 2 SO 4 The solution was then fed with oxygen; the reaction tube 1 was shaken on the shaker 5 at 200 rpm for 30 min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com