Function safety system detection method and system, electronic equipment and storage medium

A technology of functional safety and detection methods, applied in the detection of faulty computer hardware, etc., can solve problems such as low reliability of results, inability to exclude errors in diagnosis results, accumulation, etc., so as to improve the safety integrity capability and eliminate the risk of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

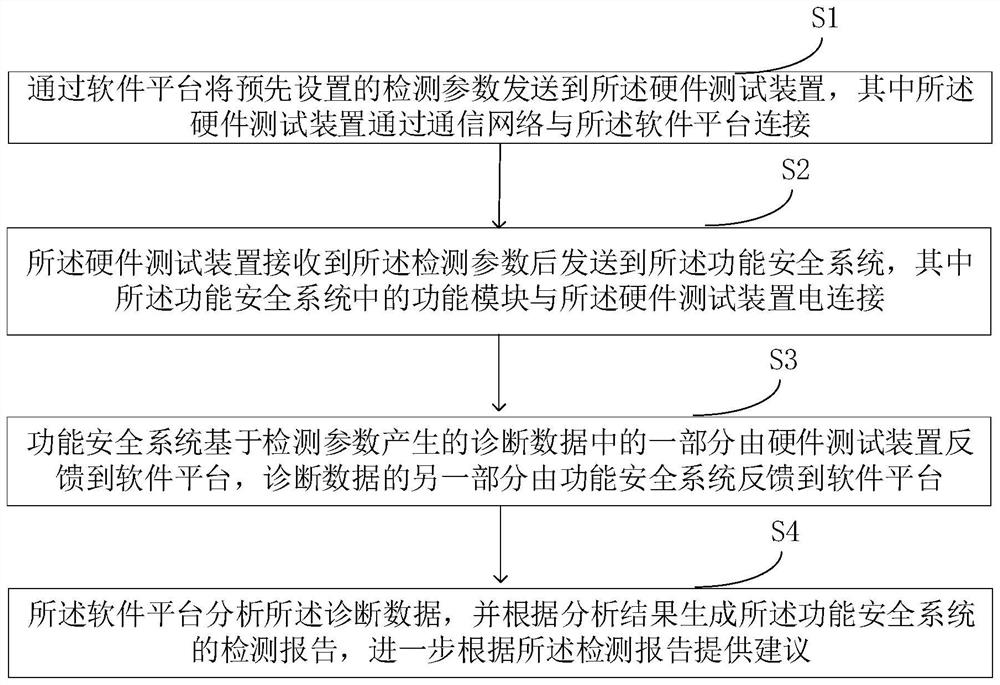

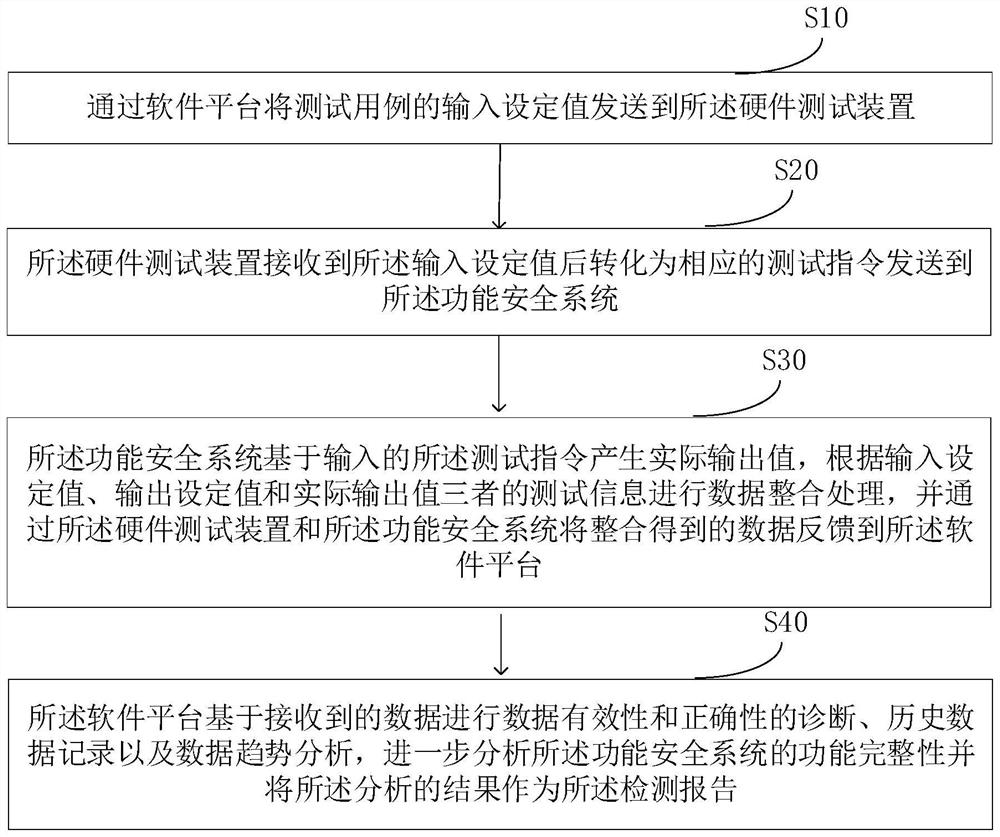

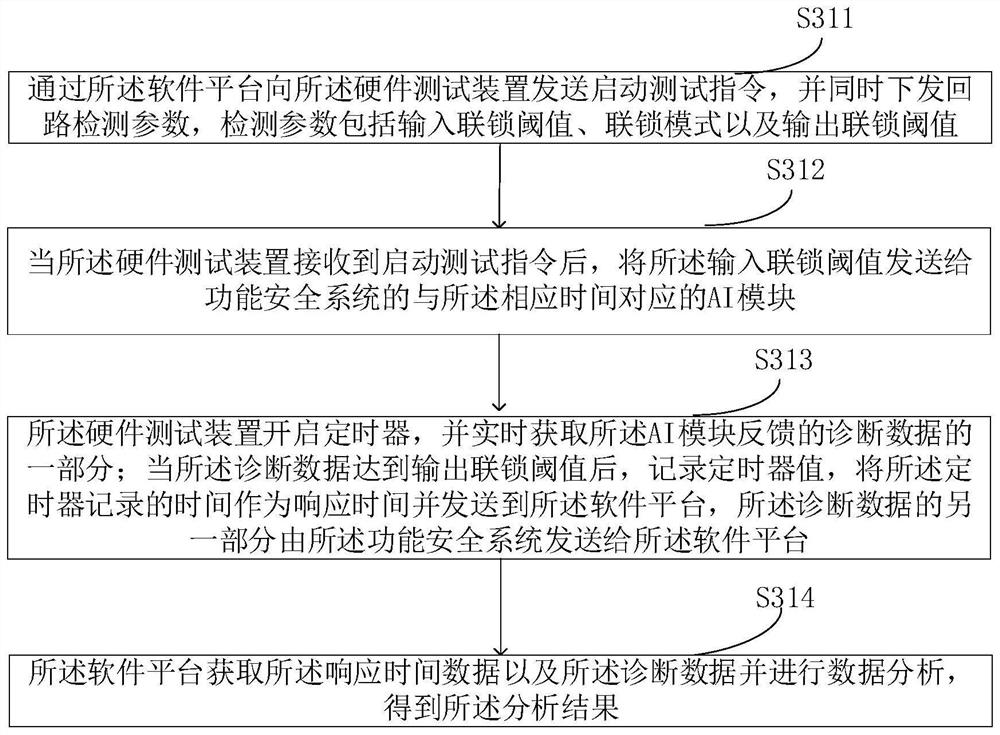

Method used

Image

Examples

Embodiment Construction

[0041] Now refer to the drawing of the example of the example. However, the example implementation method can be implemented in multiple forms and should not be understood as examples limited by this; on the contrary, these embodiments are provided to make the invention more comprehensive and complete, and to convey the idea of the example embodiments comprehensively comprehensively To the technical staff of the art. The characteristics, structure, or characteristics described can be combined in one or more embodiments in any appropriate way.

[0042] In addition, the attachment is only for the signaling of the present invention, and it is not necessarily drawn in proportion. The same attachment label in the figure represents the same or similar parts, which will omit the repeated description of them. Some square diagrams shown in the attached figure are functional entities, and do not necessarily correspond to physical or logical independent entities. These functional entities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com