Heavy adjustable rotary mechanical arm for pressing and method

A rotating machine and adjustable technology, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the clamping element is easily affected by the vibration of the tool or equipment, the operation of the clamping plate is difficult, and the clamping In order to achieve the effect of reducing the dependence on technical level, reducing the risk of human operation and shortening the processing preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

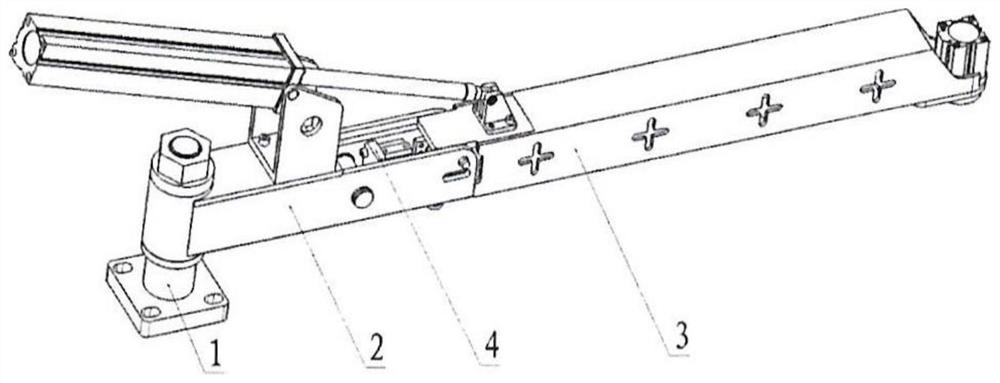

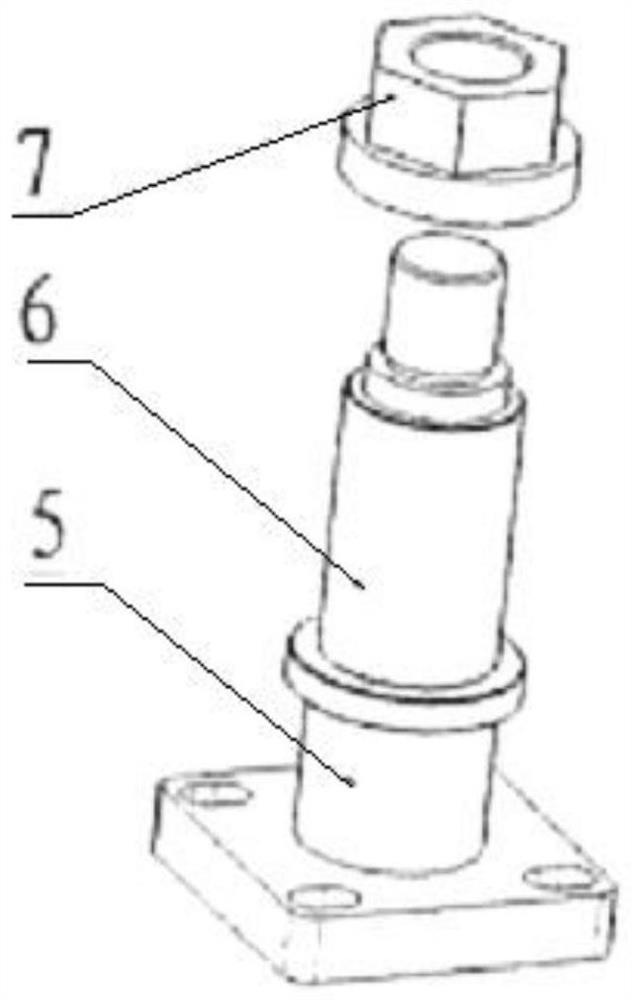

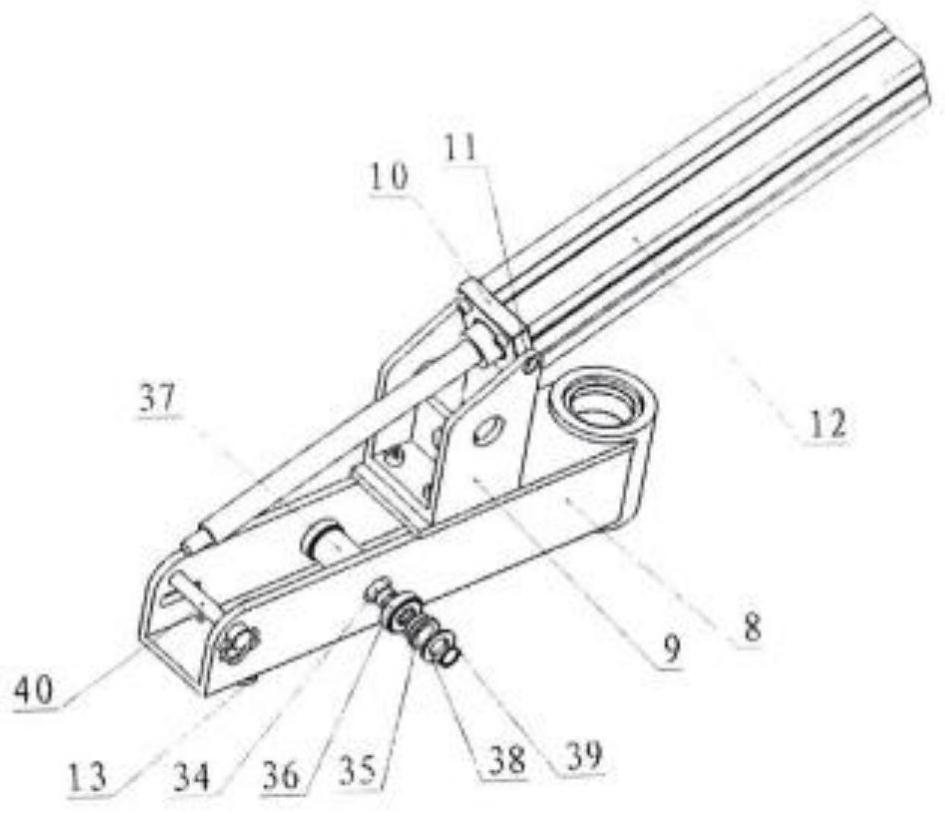

[0025] refer to Figure 1-6 , a heavy-duty adjustable rotary mechanical arm and method for pressing, comprising a base 1, a main arm 2, a support arm 3 and a lock mechanism 4, characterized in that the base 1 includes a support 5, a rotating shaft with an oil groove sleeve 6 and shoulder nut 7, the base 1 is connected to one end of the main arm 2 through the rotating sleeve 6 with an oil groove, the other end of the main arm 2 is a U-shaped opening, and one end of the support arm 3 and the locking mechanism 4 are wrapped in In the U-shaped opening of the main arm 2, the main arm 2 includes a load-bearing arm 8, an adapter seat 9, a cylinder connecting plate 10, a joint 11, a long-distance cylinder 12 and an adjusting screw 13, and the load-bearing arm 8 is composed of The sleeve and the mouth-shaped bracket are welded. The two are made of high-strength structural steel. After welding, the overall rigidity and strength provide guarantee for the load bearing of the whole set of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com