Asymmetric cone spine array oil mist collecting device and preparation and collecting method thereof

A collection device, asymmetrical technology, applied in the direction of general water supply saving, etc., can solve the problem that the collection device has no self-cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

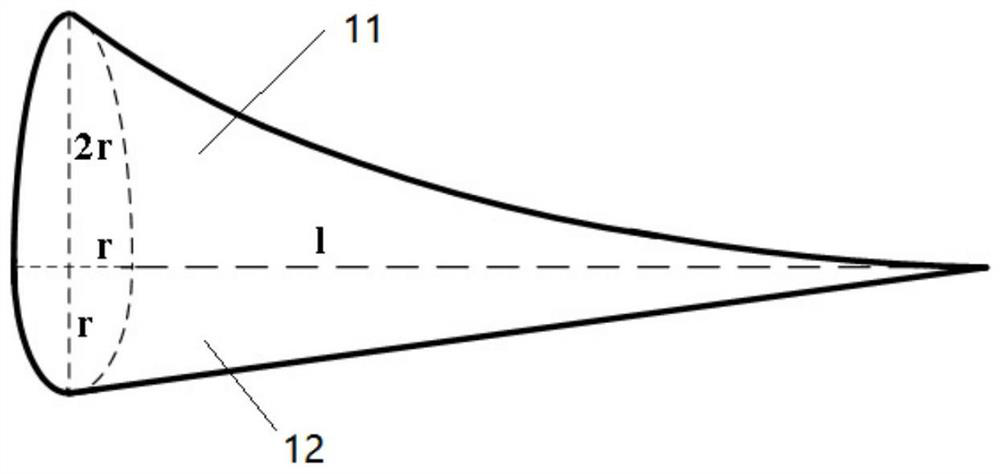

[0065] Example 1: Resin Template Re-engraving

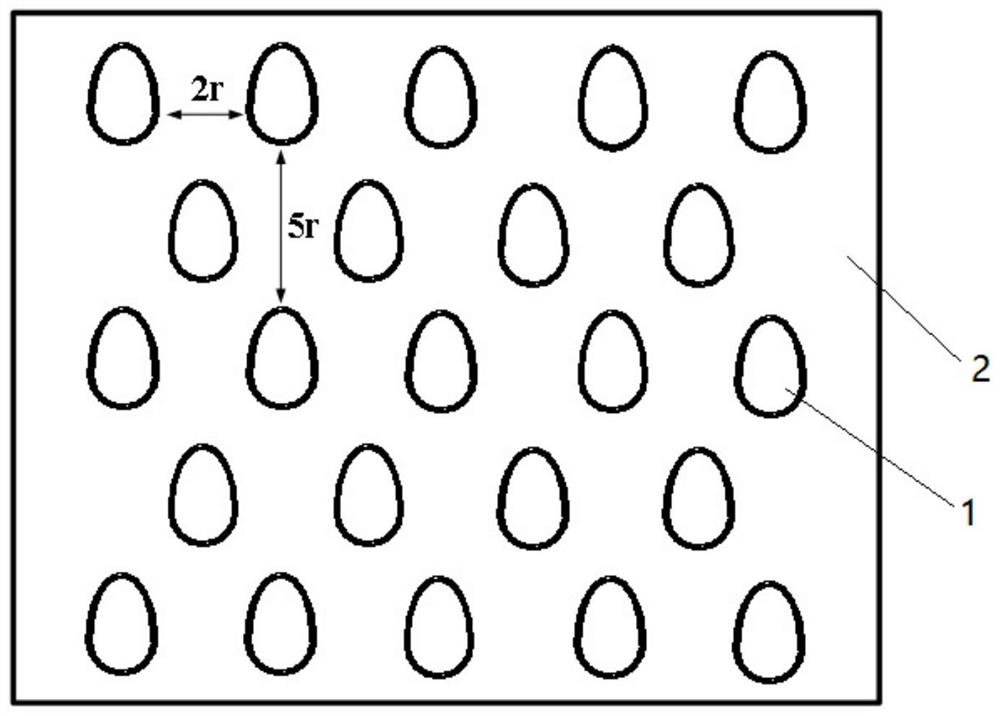

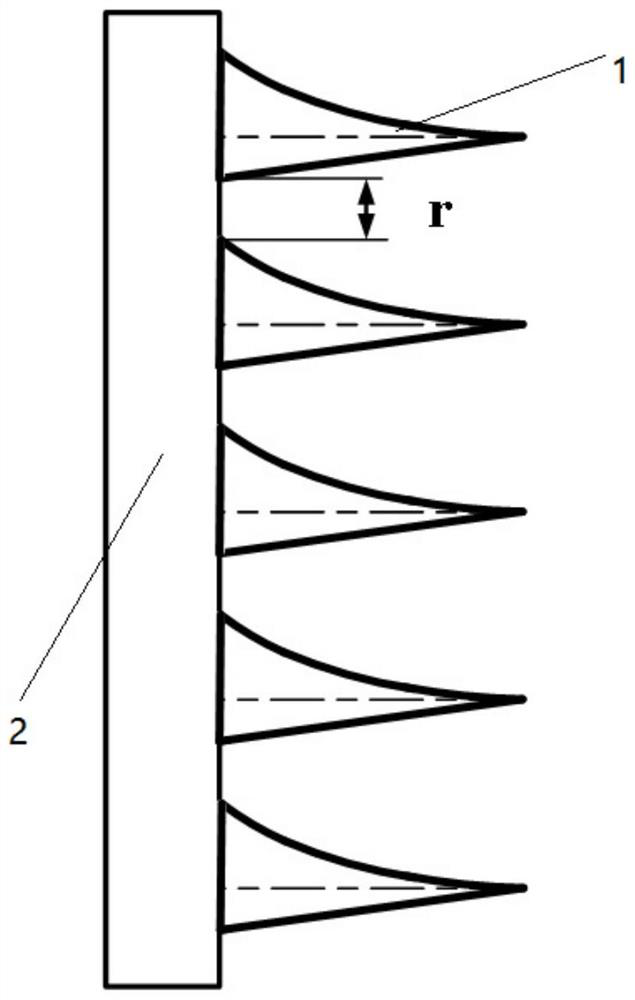

[0066] A thermosetting resin sheet (such as acrylic resin, etc.) with a thickness of 1cm is made, and the corresponding asymmetric structure metal thorn is made by machining technology and installed on a three-dimensional high-precision slide table (the precision of the slide table is 0.05mm), and controlled by PLC. Under the control of the device program, the array is taken on the resin sheet, and the array adopts the insertion row, that is, the bottom surface distance of a cone is translated between the rows.

[0067] Preferably, the distance between the thorns is the length of a single cone base, and when the length of the thorns is 0.5mm, the distance between the thorns is 0.5mm.

[0068] After the hole-piercing is completed, the obtained template is oleophobic modified, the obtained template is placed in a closed device, fluorosilane is dropped around the template, sealed, the device is placed in a 60° oven for 3 hours, the ...

Embodiment example 2

[0074] A 3D printer with a precision of 10 μm was used to print the asymmetric cone spine array, and the printing material can be selected from oleophobic photocurable resin.

[0075] Measure the contact angle of the photocurable resin to oil. If the oleophobic angle is not enough, the obtained template can be modified with low surface energy, that is, the obtained template is placed in a closed device, fluorosilane is dropped around the template, sealed, and the device is placed at 60° After 3 hours in the oven, the power of the oven was turned off and allowed to cool naturally, and fluorosilane with low surface free energy was grafted on the surface of the cone-spine array to obtain an oleophobic cone-spine array.

[0076] Dimethyl silicone oil was added to the ethyl acetate solvent, and the diluted lipophilic modification reagent was obtained by ultrasonically oscillating with an ultrasonic instrument until the gel was completely decomposed. The cone-spur array is fixed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com