Heterogeneous bimetal composite pipe bending forming method based on pipe bending robot

A bimetal clad pipe, bending forming technology, applied in the field of bimetal clad pipe bending member forming, can solve the problems of reduced performance of bimetal clad bending members, unusable bending members, cumbersome forming process, etc., and achieves high engineering application. Value, suppression of internal bond failure, high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to specific embodiments.

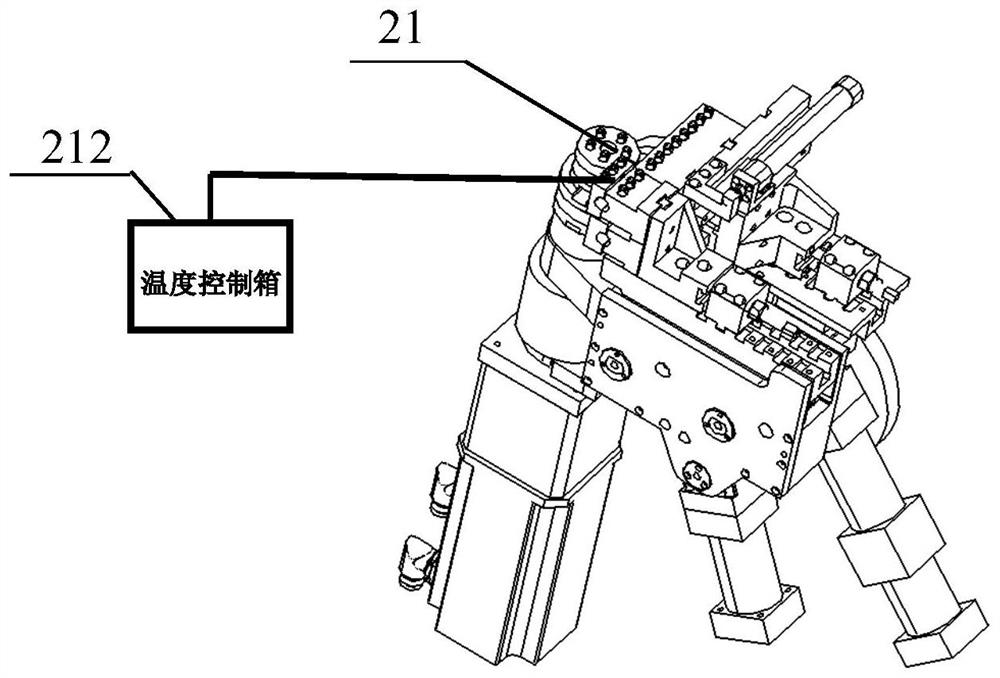

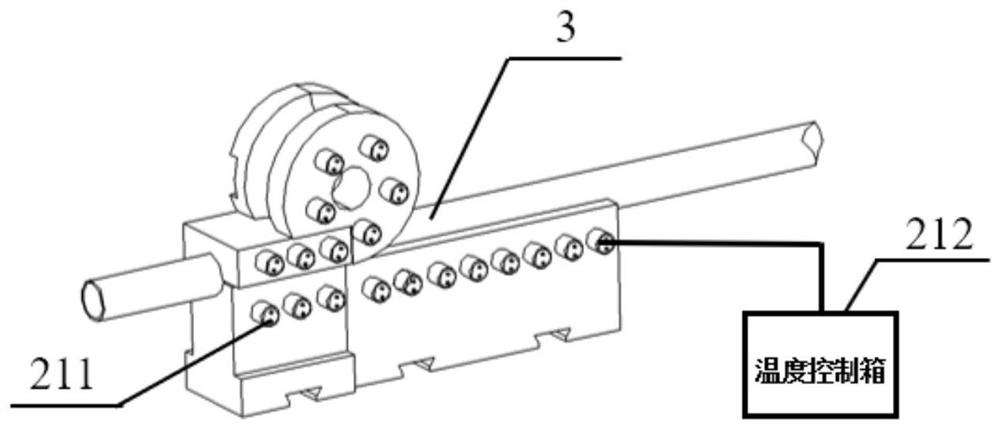

[0020] The flexible bending and forming device for bimetal composite pipe based on a pipe bending robot mainly includes a bending die 215, a main clamp 214 and an auxiliary clamp 213. The bending die 215 and the main clamp 214 are mainly used to clamp the pipe 3, and the auxiliary clamp 213 is mainly used to The bending die 215 cooperates to bend the pipe 3; and the bending die 215, the main clamp 214 and the auxiliary clamp 213 are uniformly provided with heating holes near the groove of the pipe, and the resistance heating rods 211 are filled.

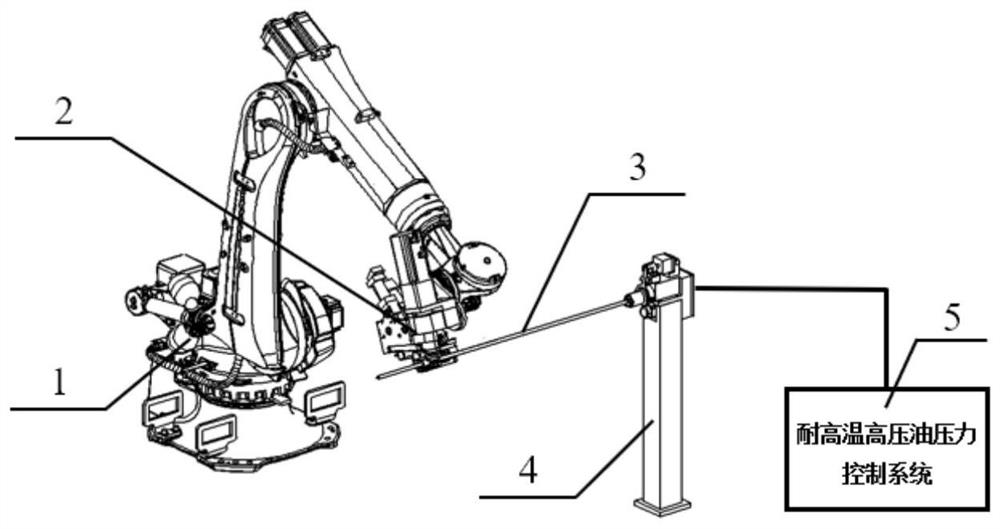

[0021] like Figure 1 to Figure 4 As shown, a method for flexible bending and forming of a bimetallic composite pipe based on a pipe bending robot is disclosed, which is characterized by comprising the following steps:

[0022] (1) Determine the inner diameter d and wall thickness t of the bimetallic composite pipe 3, and conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com