Tablet outlet baffle of tablet press

A technology of tablet press and plate body, which is applied in the field of tablet press, can solve problems such as easy knocking of tablets, and achieve the effects of reducing waste, preventing uplift, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be described in detail to the embodiments of the technical scheme of the present invention. The following examples are only used to explain the technical solutions of the present invention more clearly, so they are only used as examples, and they cannot limit the protection scope of the present invention.

[0020] It should be noted that unless otherwise explained, the technical terms or scientific terms applied for this application should be understood by the technical personnel in the field of the invention.

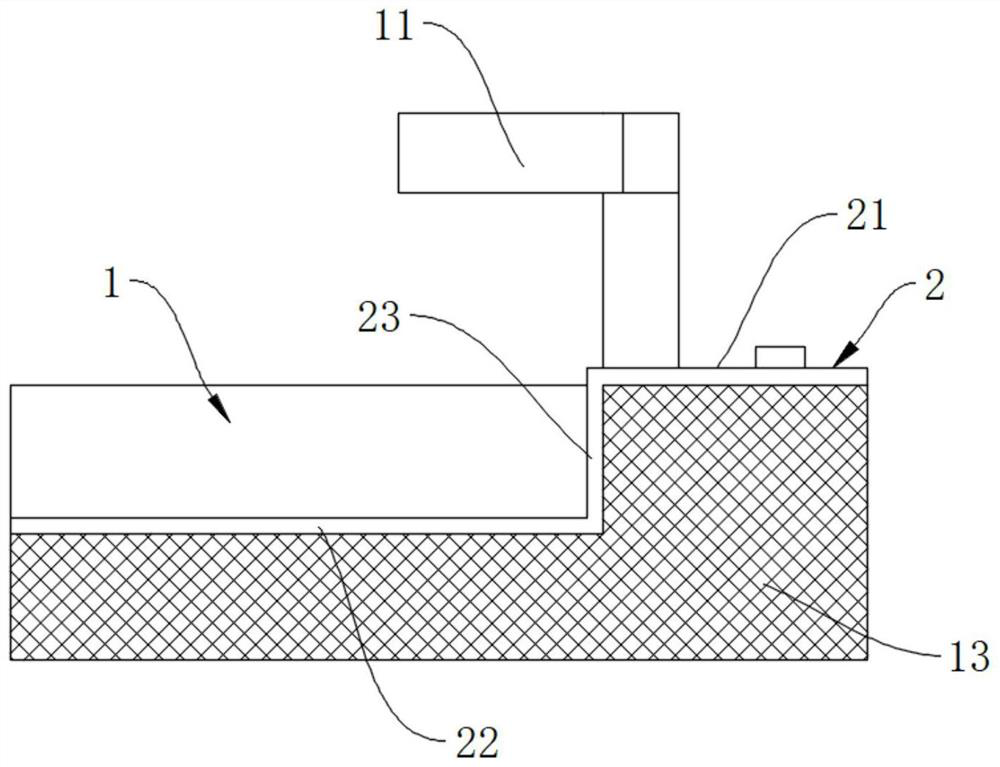

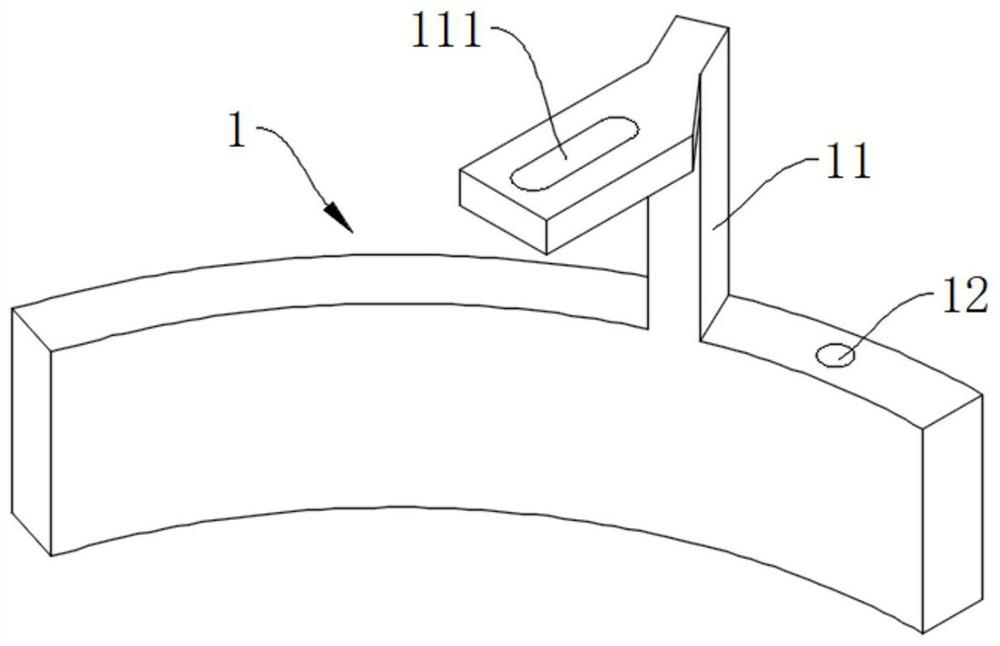

[0021] like figure 1 and figure 2 Show, this embodiment discloses a padding machine outlet, including baffle body 1. The top of the baffle body 1 has a connector 11. The connector 11 is used to Connect, including cover plate 2, the cover plate 2 is bending, including the first board body 21 and the second board body 22 arranged along the horizontal direction, the first board body 21 and the second board body 22 in the vertical direction direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com