Autotrophic nitrogen removal and full quantification treatment device and method for high-salt and high-ammonia-nitrogen wastewater

A technology for autotrophic denitrification and quantitative treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Low nitrosation load and other issues, to achieve full quantitative treatment, save treatment costs, and reduce CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

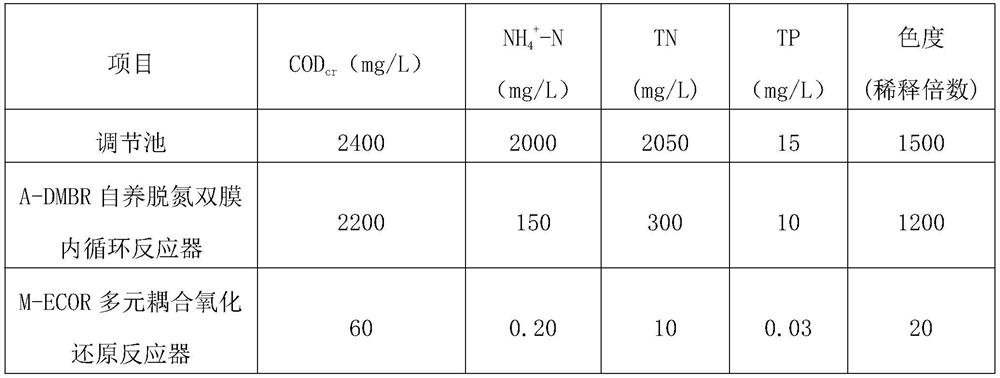

Embodiment 1

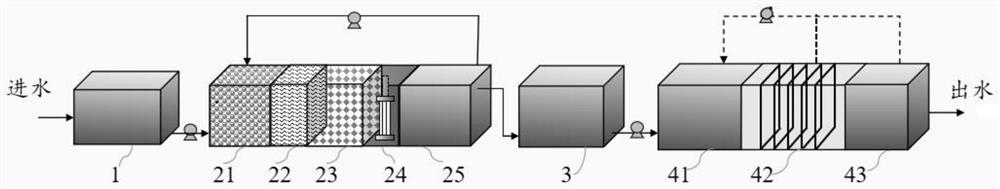

[0037] like figure 1As shown in the figure, an autotrophic denitrification and full quantification treatment device for high-salt and high-ammonia-nitrogen wastewater includes a regulating tank 1 connected in series, an A-DMBR autotrophic denitrification double-membrane internal circulation reactor, an intermediate water tank 3, an M-ECOR multi-element Coupled redox reactor;

[0038] The water outlet of the regulating tank 1 is communicated with the water inlet of the A-DMBR autotrophic denitrification double-membrane inner circulation reactor through a water inlet pipeline and a lift pump;

[0039] The water outlet of the A-DMBR autotrophic denitrification double-membrane inner circulation reactor is communicated with the water inlet of the intermediate water tank 3 through a pipeline;

[0040] The water outlet of the intermediate water tank 3 is communicated with the water inlet of the M-ECOR multi-element coupling redox reactor through a pipeline and an inlet pump.

[004...

Embodiment 2

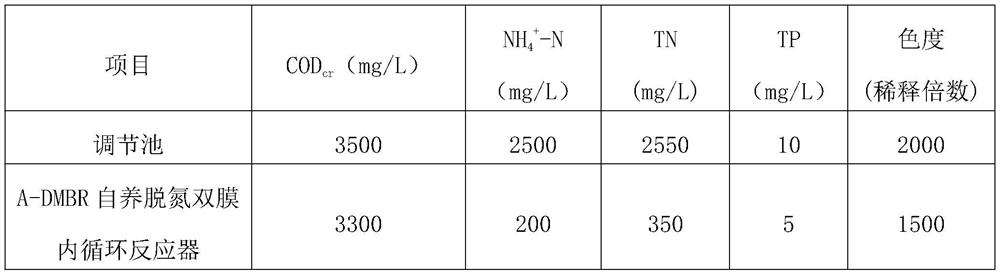

[0058] The water used in this example is the late-stage landfill leachate of a landfill, and its COD and NH 4 + The average concentrations of -N are: 3500mg / L and 2500mg / L, C / N=1.4, and the average conductivity is 25mS / cm. Compared with Example 1, in this example, the deep denitrification section 25 of the A-DMBR autotrophic denitrification double-membrane internal circulation reactor has no sulfur-containing fillers, and the autotrophic denitrification microbial chemical energy source is M-ECOR multiple coupling oxidation Reduction of the sulfides in the reflux water in the clarification section 43 of the reactor, the use of ozone as the oxidant in the pre-oxidation reduction section 41 of the M-ECOR multi-element coupled redox reactor, and the rest of the steps are the same.

[0059] After 30d of stable operation according to the process of Example 2, each treatment link of the combined device was monitored for two consecutive weeks, and its average effluent quality was sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average conductivity | aaaaa | aaaaa |

| Average conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com