Vacuum closestool

A technology for vacuum toilets and toilet seats, which is applied in construction, water supply devices, flushing toilets, etc., can solve the problems of inability to flush in place, weak flushing water, and flushing blind spots on the cleaning surface, achieving easy processing procedures, ensuring flushing effect, Improves the effect of flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

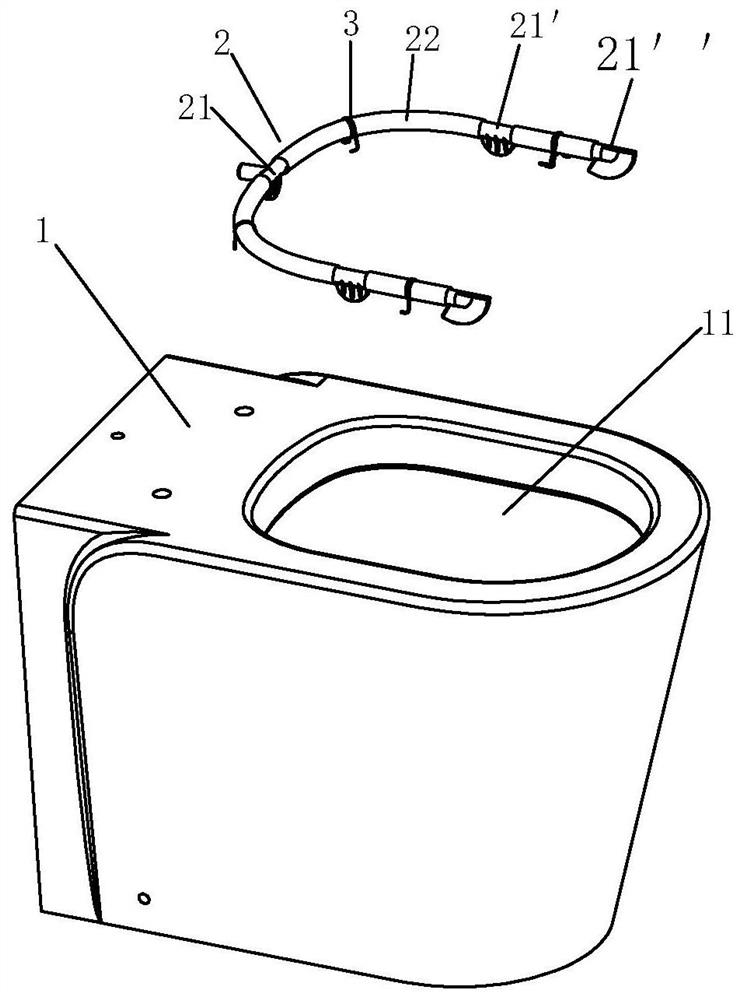

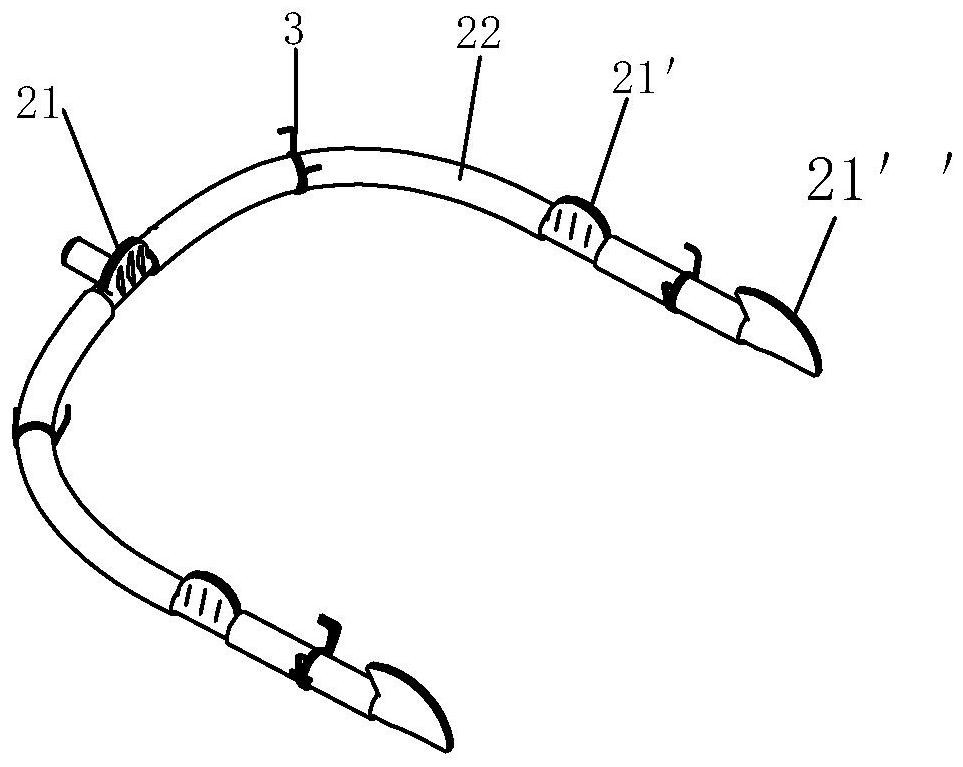

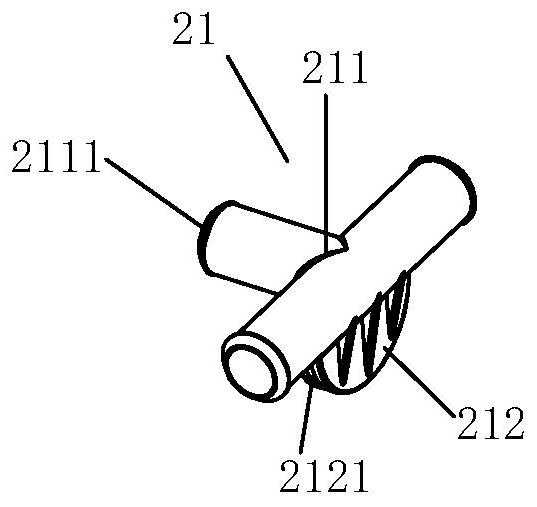

[0043] See Figure 1-Figure 13 As shown, a vacuum toilet of the present invention includes a toilet seat 1 and a water spray unit 2, the toilet seat 1 is made of ceramic material, and the bottom of the toilet 11 of the toilet seat 1 is provided with a sewage outlet 111, the sewage outlet 111 Facing down or toward the rear side of the toilet seat 1 , the sewage outlet 111 is connected to the pipeline of the vacuum system. The top of the toilet bowl 11 of the toilet seat 1 is provided with a groove 112 extending along its circumferential direction, and the notch of the groove 112 faces downward; the water spray unit 2 is arranged in the groove 112, and the The water spray unit 2 includes a plurality of nozzles and a plurality of water pipes 22, the plurality of nozzles are distributed at intervals along the circumferential direction of the groove 112, and the adjacent nozzles are connected by the water pipes 22, at least one nozzle and / or Or at least one water pipe 22 is provid...

Embodiment 2

[0052] See Figure 14-Figure 19 As shown in the figure, a vacuum toilet of the present invention is different from the above-mentioned first embodiment in that the water spray unit 2 is annular, and the part of the water spray unit 2 located at the front end of the toilet 11 is a water pipe 22' The bottom end of the water pipe 22' is provided with a plurality of water outlet holes 221 spaced along its circumferential direction. In this way, the present invention can solve the problem that the front end of the toilet is arc or V-shaped, resulting in a small space and inconvenient to install the nozzle, and ensure the flushing effect of the front of the toilet 11 .

[0053] In this embodiment, the number of the nozzles is three, but not limited to this. The three nozzles include nozzles of two different shapes. The structure of the first type of nozzle 21 is the same or substantially the same as that of the first type of nozzle 21 in the above-mentioned first embodiment. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com