Fractured oil and gas reservoir hot fluid mixing and injecting in-situ residual oil water plugging process and device

A technology for thermal fluids and oil and gas reservoirs, applied in the fields of production fluids, wellbore/well components, sealing/packing, etc., which can solve the problems of water channeling channels that cannot be blocked to a higher degree, formation compatibility problems, and the inability to recover and reuse them. To improve the development effect of water injection, reduce the water content and improve the liquid production profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation device in the present application is miniaturized, adopts thermal fluid transportation, can improve the transportation effect, and at the same time play the role of thermal fluid viscosity reduction and blocking removal, can increase the injection depth of the water blocking agent, and achieve blocking removal and efficiency enhancement.

[0054] The technical solution in this application is reasonable in design, simple in operation, good in simulation effect, wide in scope of application and low in cost. The in-situ residual oil formed after high temperature and chemical separation of crude oil from the test area is used as a water blocking agent, which effectively solves the problem. The existing water plugging agents have poor compatibility with the reservoir environment, and have problems of sensitivity and pollution.

[0055] The Jiamin effect is a resistance effect. During the injection process of the device in this application, discrete oil droplet...

Embodiment

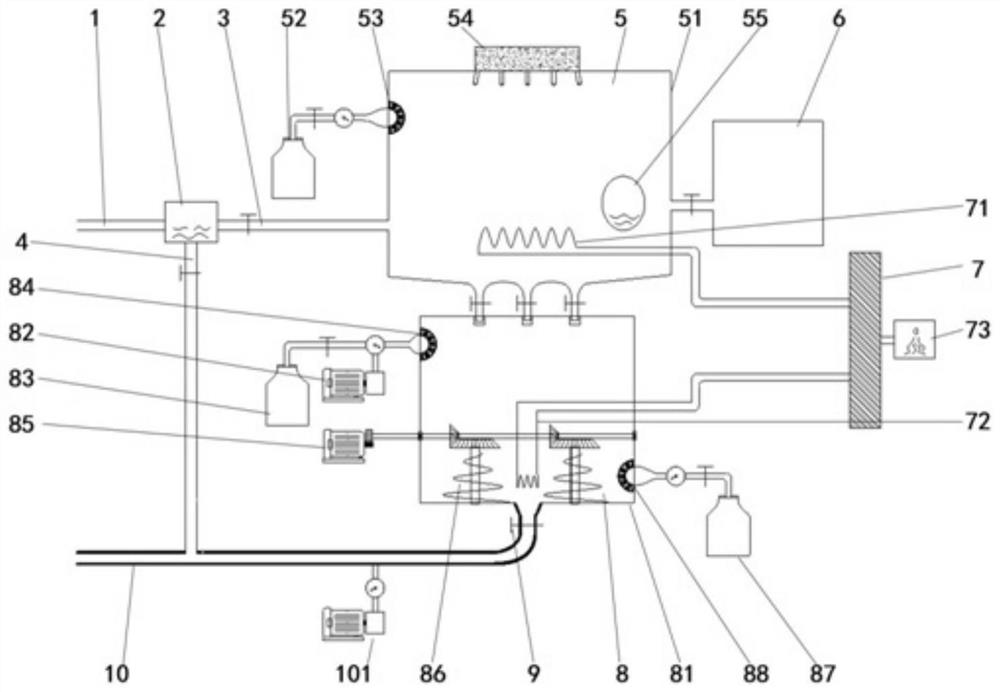

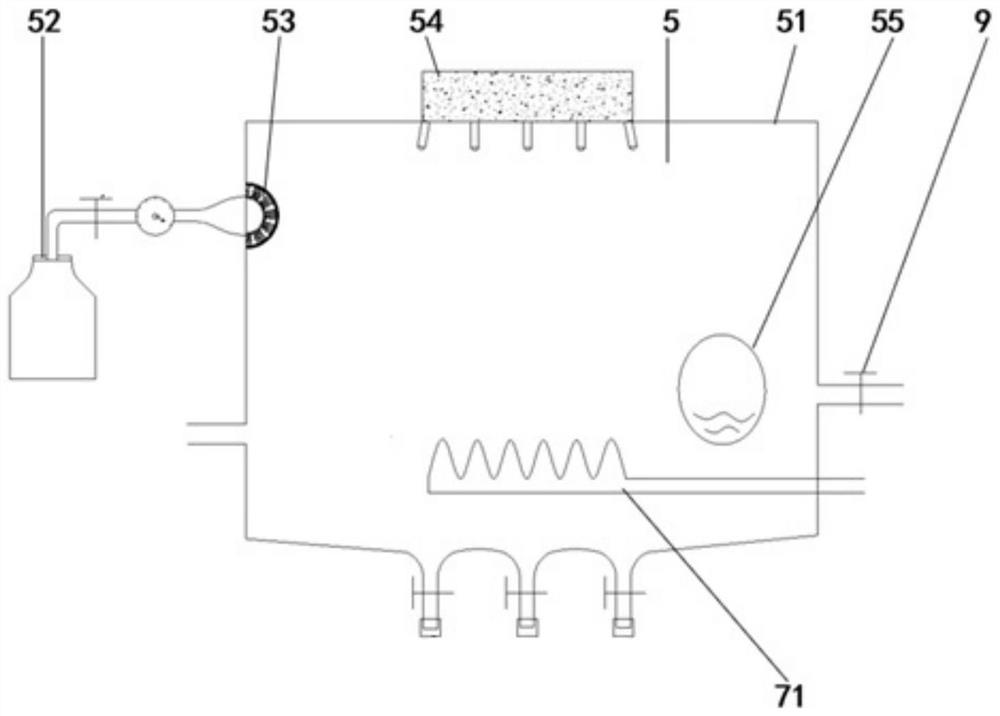

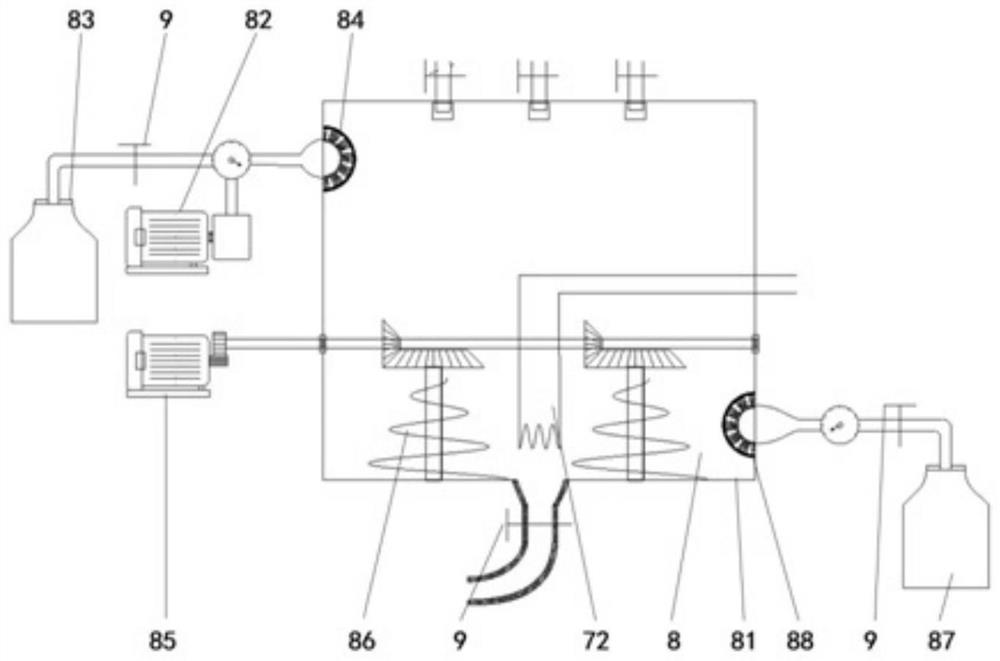

[0057] like figure 1 , figure 2 , image 3 A thermal fluid mixing in-situ residual oil water blocking device in a fractured oil and gas reservoir is shown, including an input pipeline 1, a small oil-water separator 2, an oil flow pipeline 3, a water flow pipeline 4, an oil residue separation reactor 5, Oil storage tank 6, heating assembly 7, thermal fluid mixing and dilution reaction kettle 8, control valve and injection pipeline 10, valve 9 is provided between injection pipeline 10 and thermal fluid mixing and dilution reaction kettle 8, wherein input pipeline 1 and The left side of the small oil-water separator 2 is connected, the right side of the small oil-water separator 2 is connected with the oil flow line 3, the lower part is connected with the water flow line 4, the water flow line 4 is connected with the injection line 10, and the oil flow line 3 is connected with the oil residue separation reactor 5 Connected to the left. The oil residue separation reactor 5 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com