Marine cooling system

A cooling system, marine technology, applied in the direction of liquid cooling, engine cooling, machine/engine, etc., can solve the problems of affecting the service life of pipelines, effectively recovering heat energy from seawater environmental pollution, damage to cooling system pipelines, etc., to avoid water leakage , to ensure stable and efficient operation, and to improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

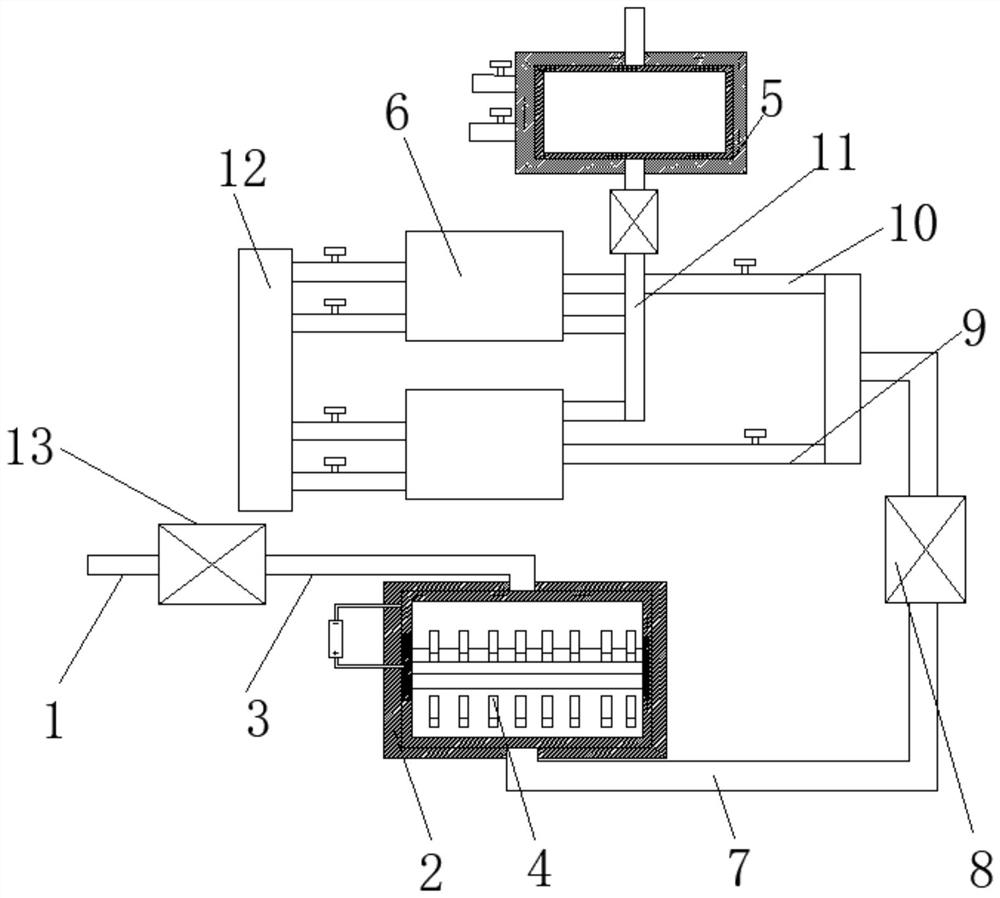

[0028] like figure 1 As shown, a marine cooling system includes a seawater inlet pipe 1, a water pump 13 connected to the seawater inlet pipe 1, a No. 1 conduit 3 connected to the output end of the water pump 13, a processing tank 2 communicating with the No. 1 conduit 3, and a The No. 2 conduit 7 that communicates inside the box 2, the No. 1 branch pipe 9 and the No. 2 branch pipe 10 that are located on the side of the No. 2 conduit 7 away from the processing box 2 and communicated with the inside of the No. 2 conduit 7 respectively, also include the No. 1 branch pipe 9 and the No. The second branch pipe 10 is connected to a cooling assembly 6 for cooling high temperature water in the diesel engine 12, a drain pipe 11 located on the cooling assembly 6, a recovery tank 5 located at the output end of the drain pipe 11 for recovering heat energy, located in the processing tank 2 and Electrolyzer 4 for de-corrosion treatment of seawater.

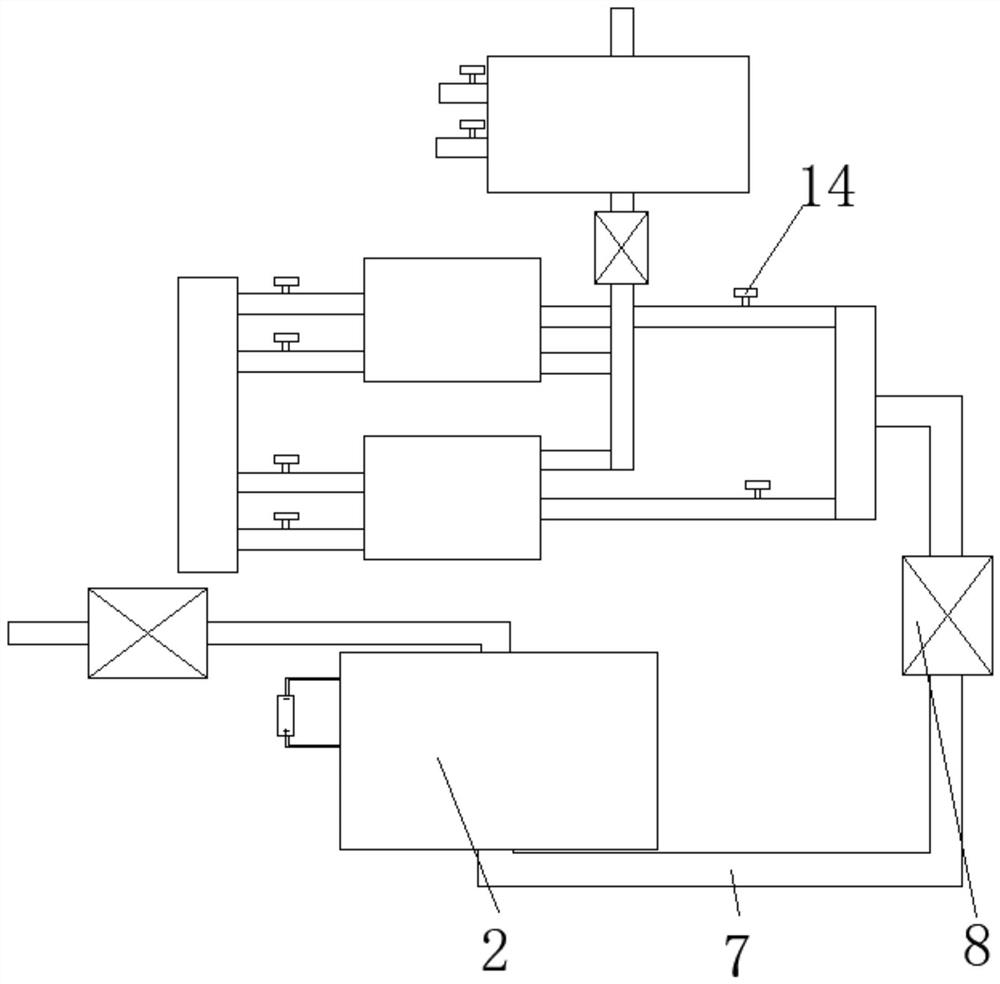

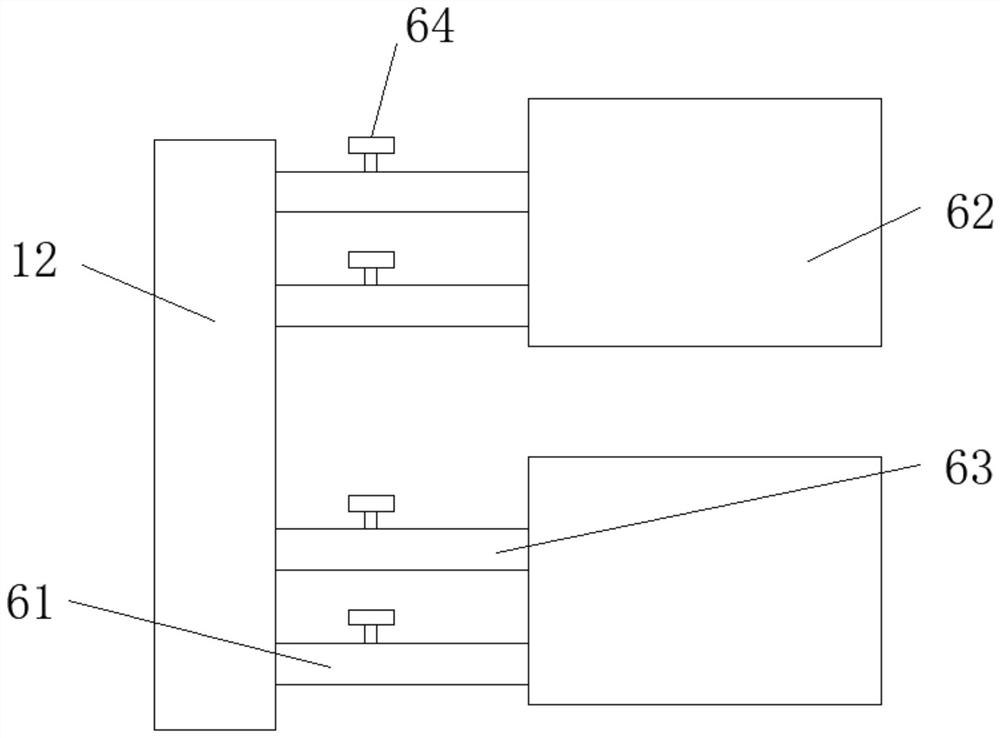

[0029] like figure 2 and image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com