Multi-gear fixed shaft type gear shifting gearbox

A gearbox and fixed-shaft technology, which is applied in the field of multi-gear fixed-shaft shift gearboxes, can solve the problems that the maximum speed ratio of the gearbox can only reach 6, increase the difficulty and cost of processing and manufacturing, and fail to meet the requirements. Achieve the effect of improving smoothness of operation, less processing difficulty and less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

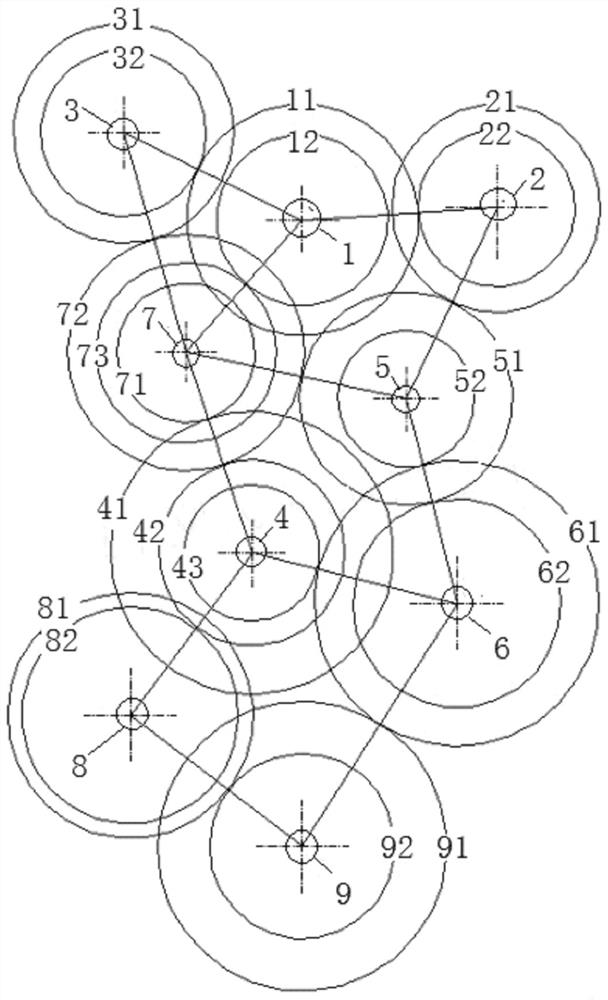

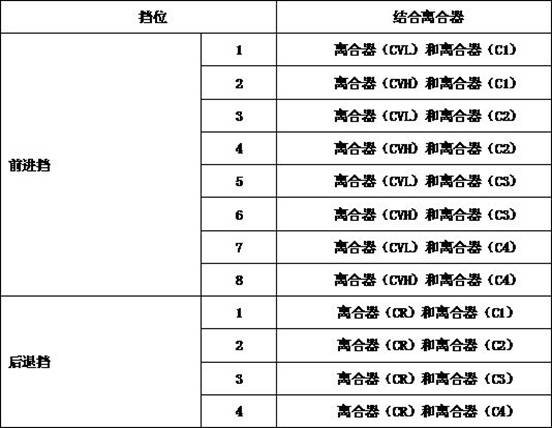

[0042] see figure 1 , figure 2 As shown, this embodiment provides a multi-speed fixed-shaft shift gearbox. The gearbox includes S-in shaft 1, SVH shaft 2, SR shaft 3, S1 shaft 4, S2 shaft 5, S3 shaft 6, SVL shaft 7, S4 shaft 8 and S-out shaft 9 and multiple clutches. The plurality of clutches are CR clutch 33 , CVH clutch 23 , C1 clutch 44 , C2 clutch 53 , C3 clutch 63 , CVL clutch 74 , and C4 clutch 83 . The S-in shaft 1 is connected with the engine to receive power for transmission. The S-in shaft 1 is installed with a first fixed gear 11 and a second fixed gear 12, and the S-out shaft 9 is connected with the transmission shaft, which can connect the S- The in axle 1 is used to transmit the received power to the vehicle. A sixth fixed gear 91 and a seventh fixed gear 92 are mounted on the S-out shaft 9 . The SVH shaft 2 is equipped with a third fixed gear 21, a first floating gear 22 and a CVH clutch 23; the CVH clutch 23 is connected with the first floating gear 22 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com