Smoke exhaust pipe, smoke exhaust system and gas water heater

A technology for gas water heaters and smoke exhaust pipes, which is applied to water heaters, fluid heaters, exhaust gas exhaust devices, etc., can solve the problems of shortening the service life of water heaters by smoke exhaust pipes, and achieve the purpose of avoiding unsmooth smoke exhaust, convenient manufacture, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

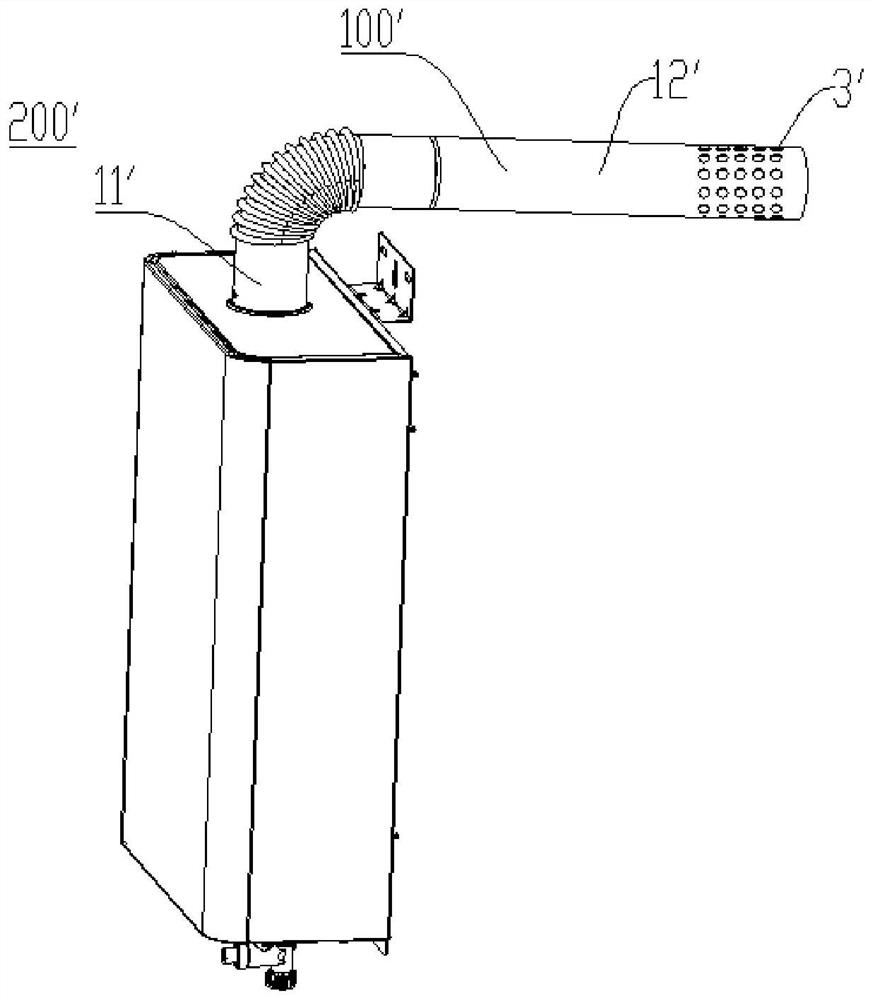

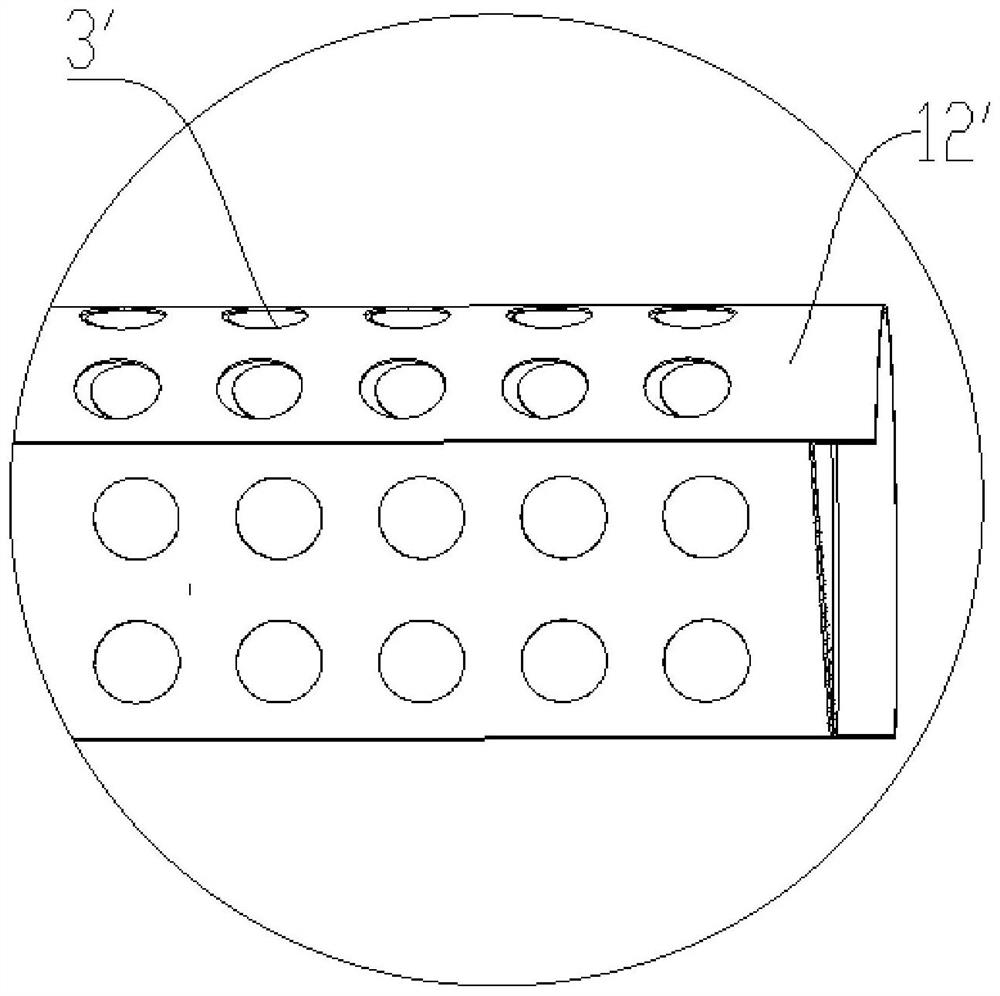

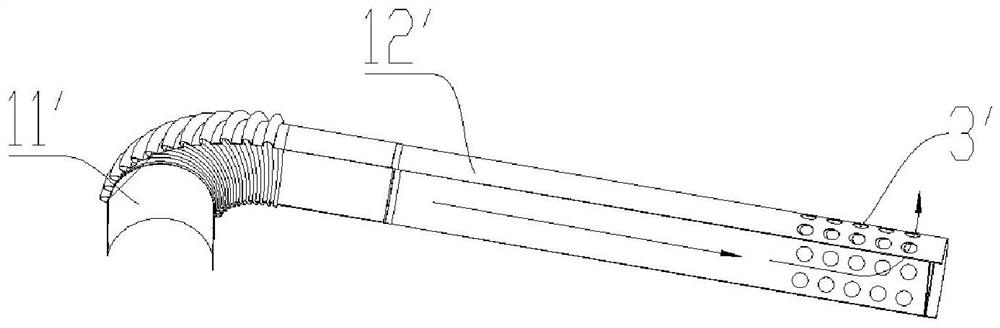

[0042] Figure 4 It is the gas water heater of Embodiment 3 of the present invention. Figure 5It is the exhaust pipe of the gas water heater according to the third embodiment of the present invention. like Figure 4 and Figure 5 As shown, the smoke exhaust pipe 100 in this embodiment mainly includes a pipe body and a smoke exhaust port 3 . The pipe body has a first section 11 suitable for connecting with the main body 201 of the gas water heater 200 and a second section 12 connecting with the first section 11 . The extending direction of the first segment 11 and the extending direction of the second segment 12 form an included angle. At least the inner tube wall of the second section 12 is recessed outward to form a groove 2 at the lower side thereof. For example, the second section 12 can be configured so that only the inner tube wall of the lower side is recessed outward to form a groove, or it can be configured that both the inner tube wall of the lower side and the ...

Embodiment 2

[0051] Embodiment 2 relates to a smoke exhaust system, which includes the above-mentioned smoke exhaust pipe 100, so it has the beneficial effect, that is, it can overcome the fact that the smoke exhaust pipe 100' in the prior art is prone to shorten the water heater due to the backflow of rainwater. defects in the service life.

Embodiment 3

[0053] Embodiment 3 relates to a gas water heater 200. The gas water heater 200 includes the above-mentioned smoke exhaust pipe 100, so it has the beneficial effect, that is, it can overcome the fact that the smoke exhaust pipe 100' in the prior art is easily shortened due to the backflow of rainwater. defects in the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com