Pantograph slide plate wear state detection method based on laser displacement sensor

A pantograph sliding plate, laser displacement technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of poor camera stability and anti-interference ability, complicated installation, etc., to improve detection accuracy and simple system structure design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

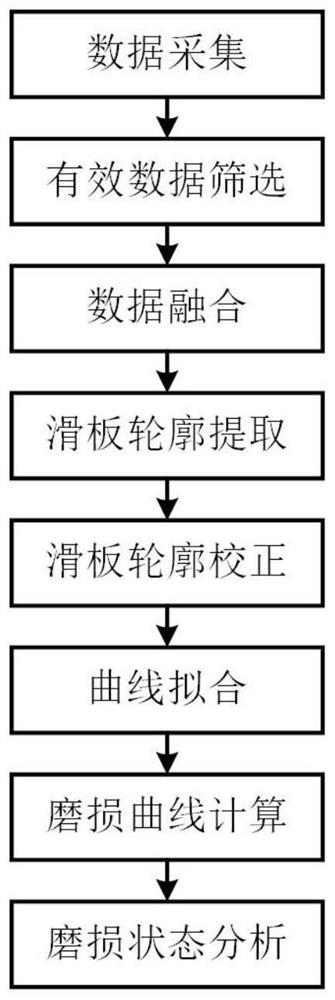

[0103] combine figure 1 , a method for detecting the wear state of a pantograph slide plate based on a laser displacement sensor of the present invention, comprising the following steps:

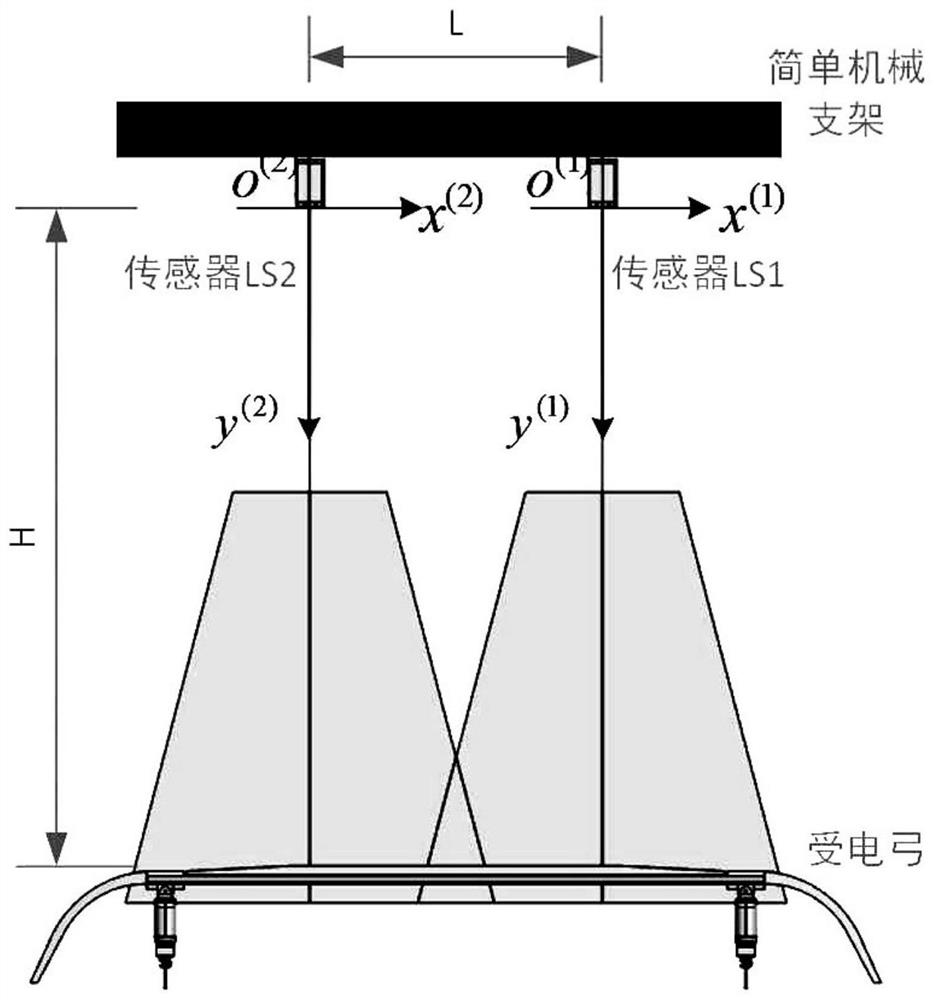

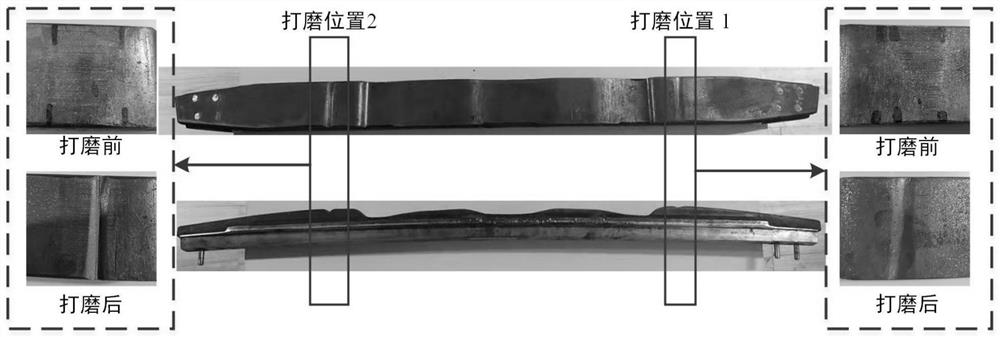

[0104] S1: Two sets of laser displacement sensors are installed mirror-symmetrically about the center line of the rail, and the slide plate data is collected vertically downward. The sensor installation is shown as follows figure 2 shown, the test skateboard is as image 3 The specific process is as follows:

[0105] S11: The laser displacement sensor adopts a high-precision and large-range 2D laser displacement sensor, and the Keyence LJ-X8900 sensor is selected;

[0106] S12: Two sets of laser displacement sensors are installed above the contact line, and are mirror-symmetrical about the center line of the track, and the horizontal distance between the laser source points of the two sets of laser displacement sensors is 550mm;

[0107] S13: The laser displacement sensor is installed ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com