Composite battery winding equipment

A composite battery and equipment technology, applied in the field of composite battery winding equipment, can solve the problems affecting the yield and production efficiency of battery cells, the folding or wrinkling of the winding dust pole pieces, and the poor alignment of deviation correction, etc., to reduce the number of pieces. Total quantity, effect of reducing coil dust, reducing the likelihood of folds or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

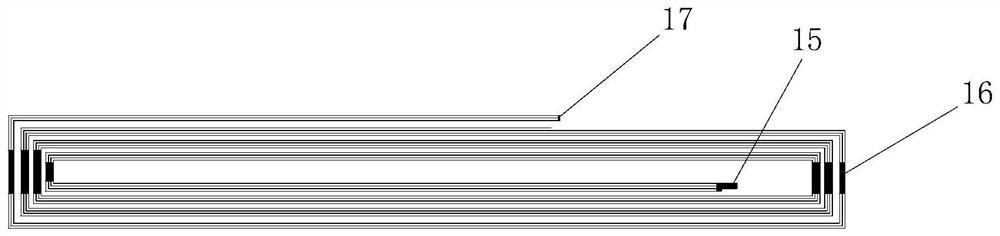

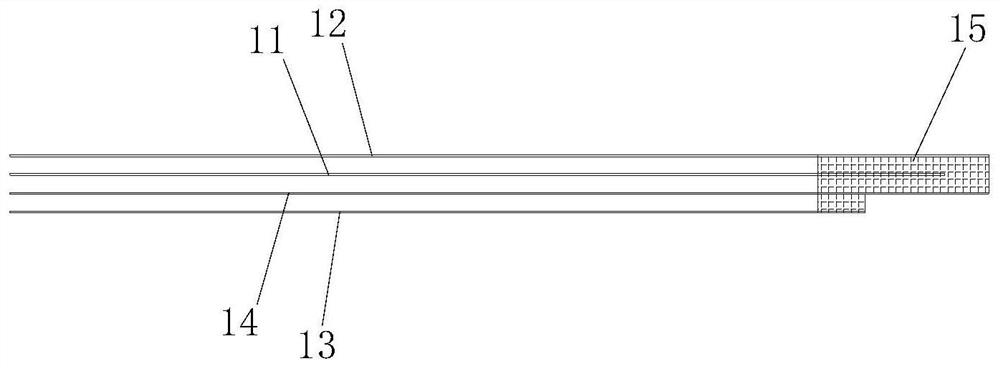

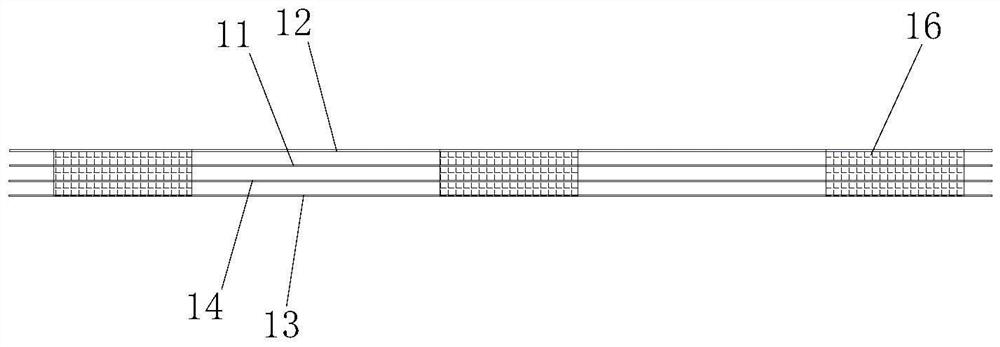

[0037] This embodiment provides a composite battery winding device. The device consists of a positive electrode composite unit, a negative electrode composite unit, and a positive and negative composite unit connecting the positive electrode composite unit and the negative electrode composite unit. The positive electrode composite unit is used for the positive electrode sheet 11. The head and tail are heated and combined with the first separator 12 to form a positive composite sheet, and the negative composite unit is used to heat the head and tail of the negative sheet 13 and the second separator 14 to form a negative composite sheet. The positive and negative composite units are used for The positive electrode composite sheet body and the negative electrode composite sheet body are wound to form a battery cell, and the head, turning portion and tail portion of the battery cell are heated and composited in turn to form a cell such as Figures 1 to 4 Head compound 15, corner co...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment lies in the compounding method of the battery cells. The positive electrode sheet 11 and the first separator 12 are heated and compounded over the entire length of the positive electrode compound unit to form a positive electrode compound sheet body. The whole length of the second separator 14 is heated and composited to form a negative electrode composite sheet, and then the positive and negative composite sheets are compositely wound through the positive and negative composite units to form a composite sheet such as Figures 11 to 14 cells shown.

[0043] In summary, the composite battery winding equipment has the following characteristics:

[0044] 1) First, the positive electrode sheet and the first separator are compounded to form a positive electrode composite sheet body, the negative electrode sheet and the second separator are compounded to form a negative electrode composite sheet body, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com