Lattice type large antenna azimuth seat frame with tower footing

An antenna azimuth and grid structure technology, applied in antennas, antenna parts, antenna supports/mounting devices, etc., can solve the problem of reducing antenna anti-wind load disturbance and anti-overturning moment, unable to meet the needs of large reflector antennas, Reduce the ability of the seat frame to withstand horizontal loads, etc., to achieve the effect of improving the anti-overturning ability, avoiding contact stress differences, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

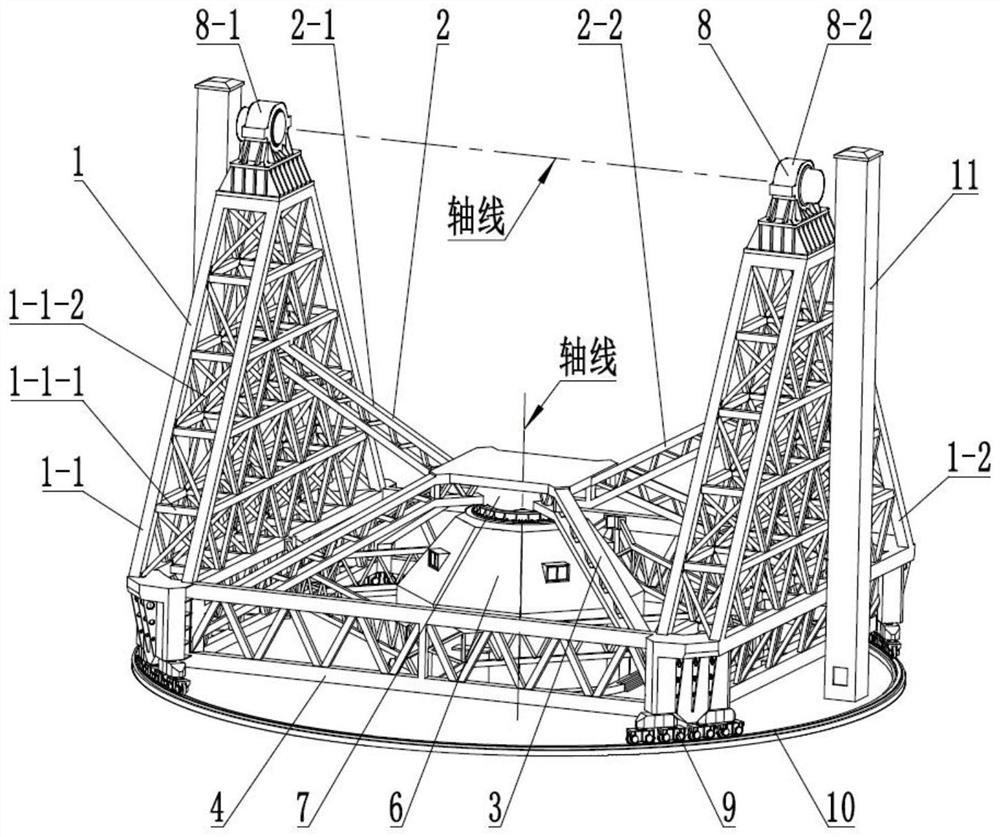

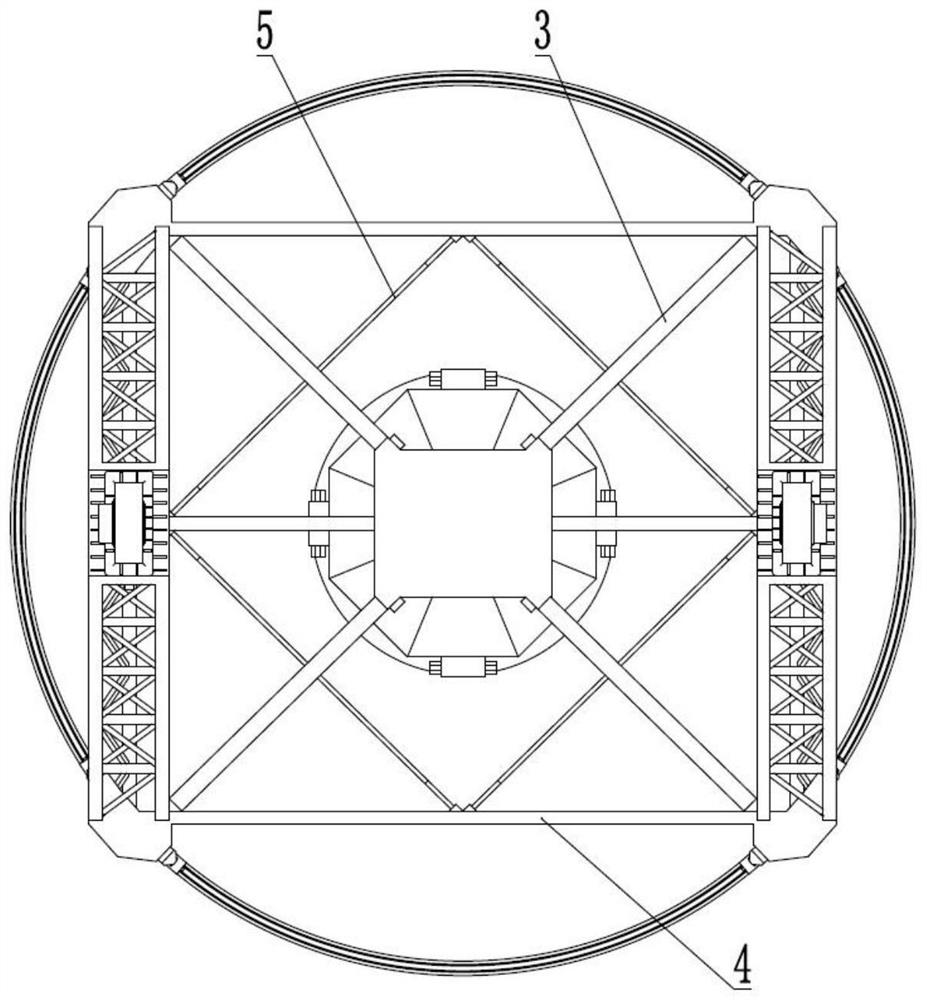

[0048] The embodiment of the present invention uses a reflector antenna with an aperture greater than 50 meters as an example, such as figure 1 As shown, the azimuth seat frame of the present invention includes: a main support truss 1, a side support beam 2, a radial inclined beam 3, a lower side beam 4, an inner inclined beam 5, a center tower base 6, a center pivot 7, a bearing seat 8, Roller mechanism 9 and track 10.

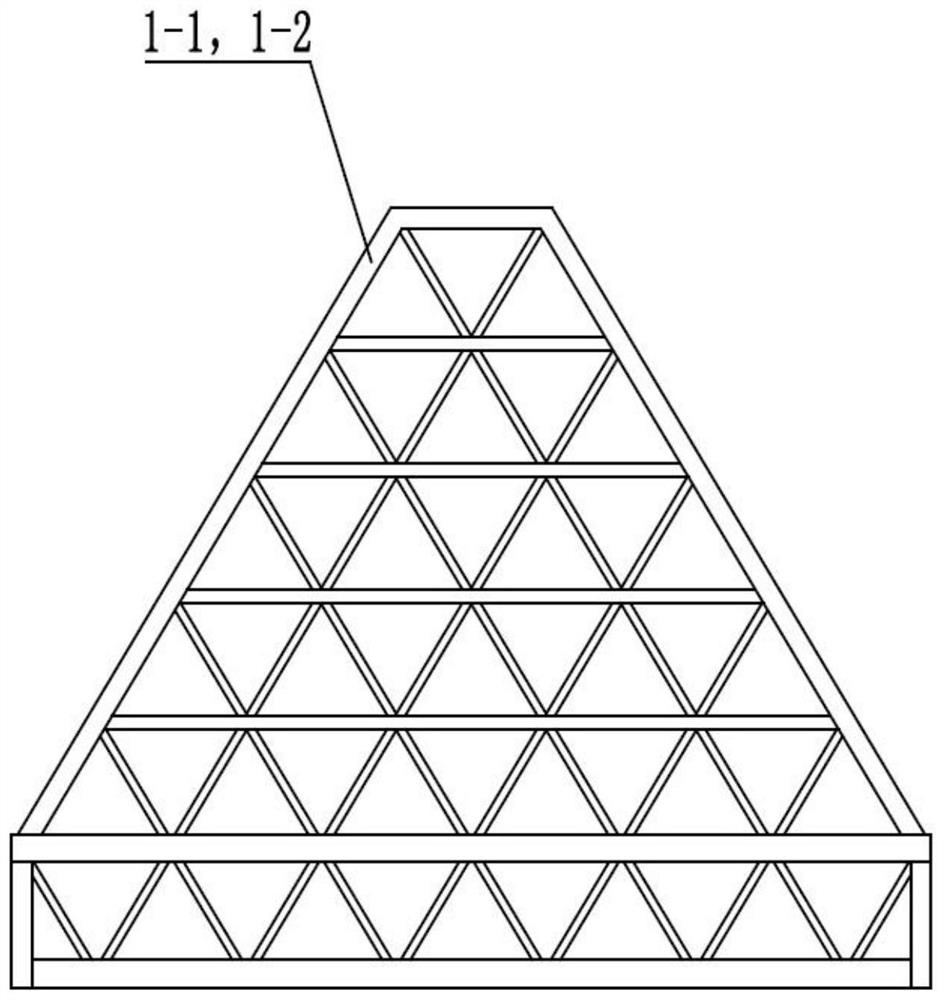

[0049] like Figures 1 to 3 As shown in the figure, the main support truss 1 is composed of a left main support truss 1-1 and a right main support truss 1-2, which are arranged symmetrically on the left and right. The outlines of the left main support truss 1-1 and the right main support truss 1-2 are The triangular and double-layer lattice structure is composed of several regular triangular meshes, and there are multiple beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com