Gel electrolyte and gel electrolyte battery

A gel electrolyte and electrolyte salt technology, which is applied in the field of gel electrolyte batteries, can solve problems such as insufficient initial charge/discharge efficiency, difficulty in preparing battery capacity, and degradation of cycle performance, and achieve excellent chemical stability and initial charge/discharge efficiency. and the effect of capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe the embodiments of the present invention

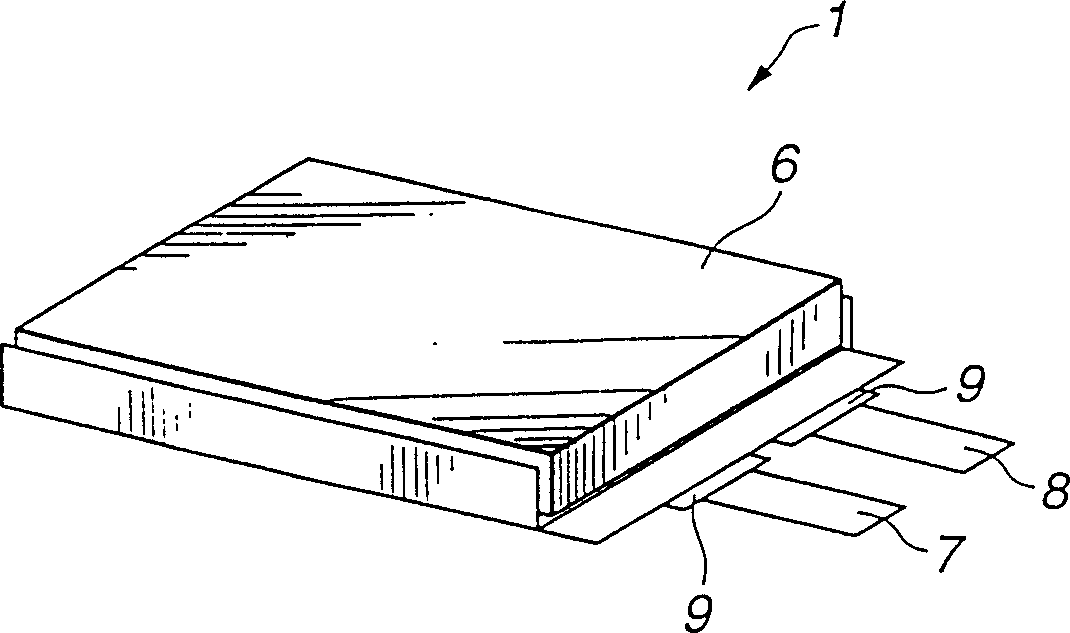

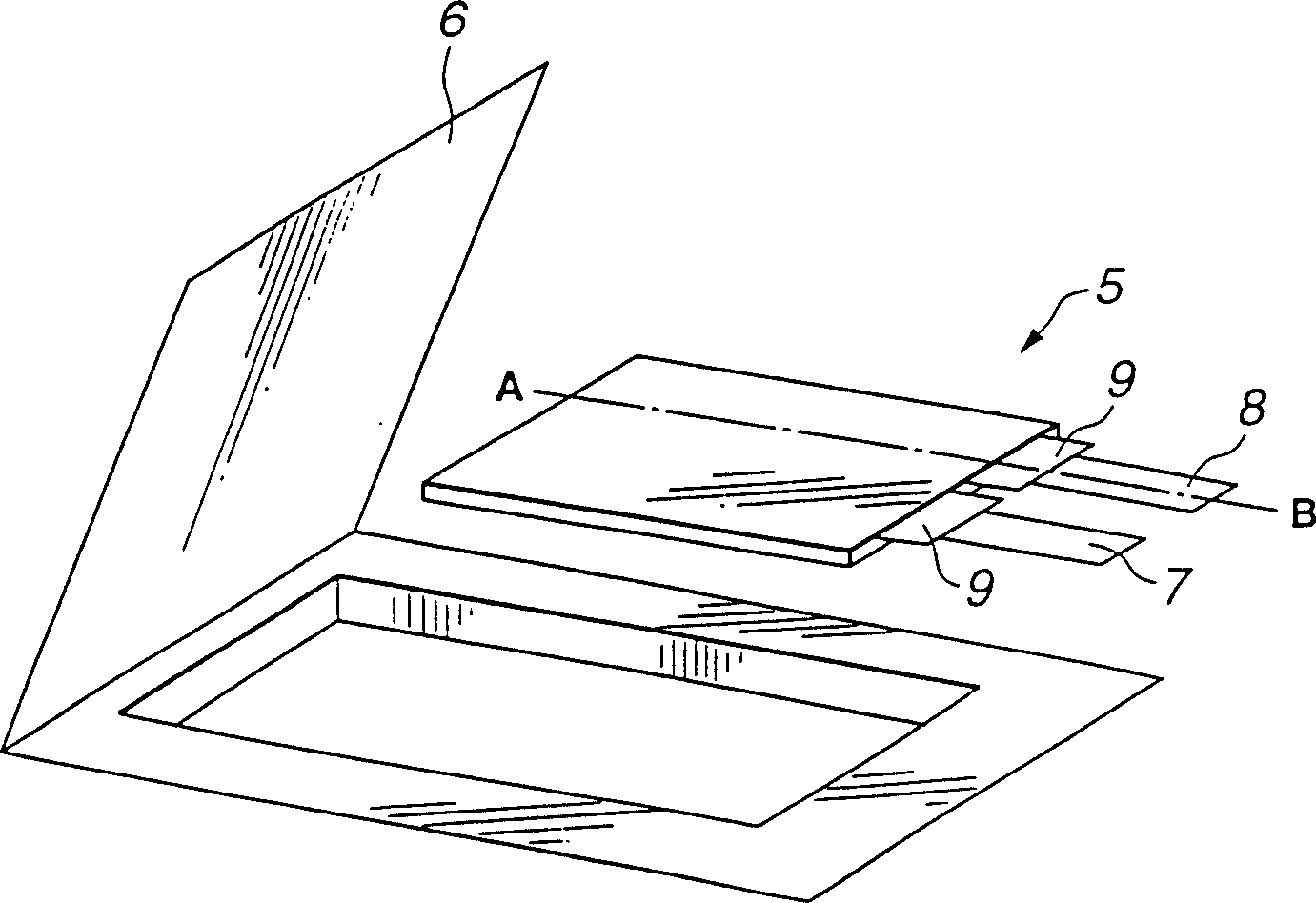

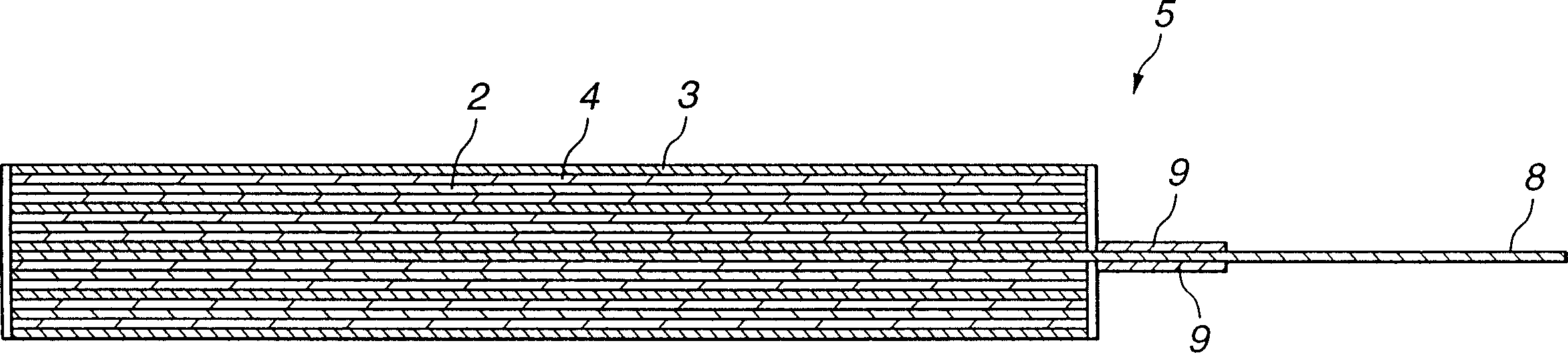

[0019] Figure 1-Figure 3 A structural example of a gel electrolyte battery according to an embodiment of the present invention is shown. Such as image 3 As shown, the gel electrolyte battery 1 includes a strip-shaped positive electrode 2 , a strip-shaped negative electrode 3 disposed opposite to the positive electrode 2 , and a gel electrolyte layer 4 between the positive electrode 2 and the negative electrode 3 . In this gel electrolyte battery 1, a positive electrode 2 and a negative electrode 3 are laminated via a gel electrolyte layer 4, rolled in the longitudinal direction, as figure 2 and image 3 The illustrated rolled electrode body 5 is covered and sealed with a casing film 6 formed of an insulating material. The positive terminal 7 is connected to the positive pole 2 and the negative terminal 8 is connected to the negative pole 3 . The positive terminal 7 and the negative terminal 8 are inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com