Evaporator system

A technology of evaporator and refrigeration capacity, applied in the direction of evaporator/condenser, household refrigeration device, cooler, etc., can solve the problems of large number of parts, expensive welding device, high installation cost, achieve precise location and avoid refrigeration loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

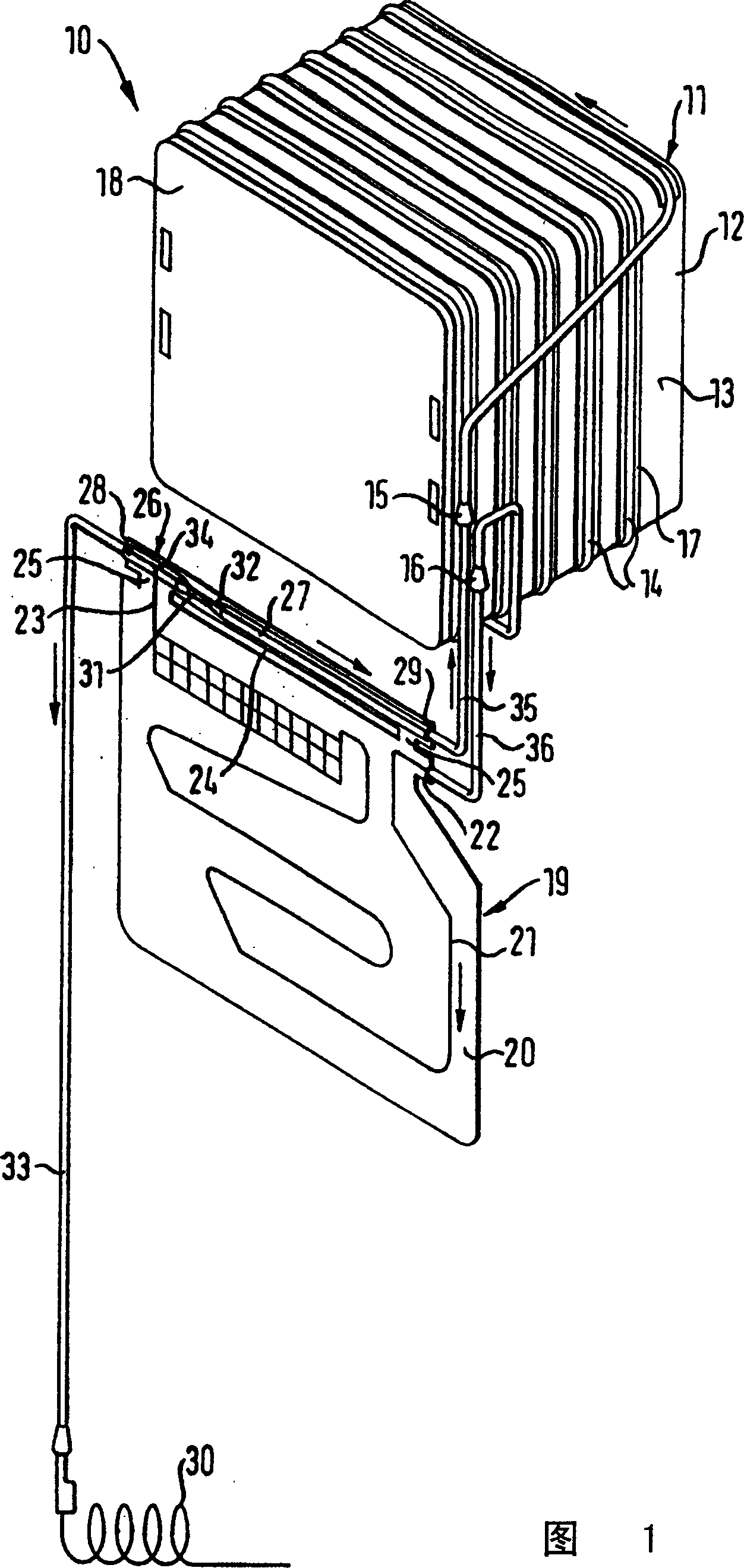

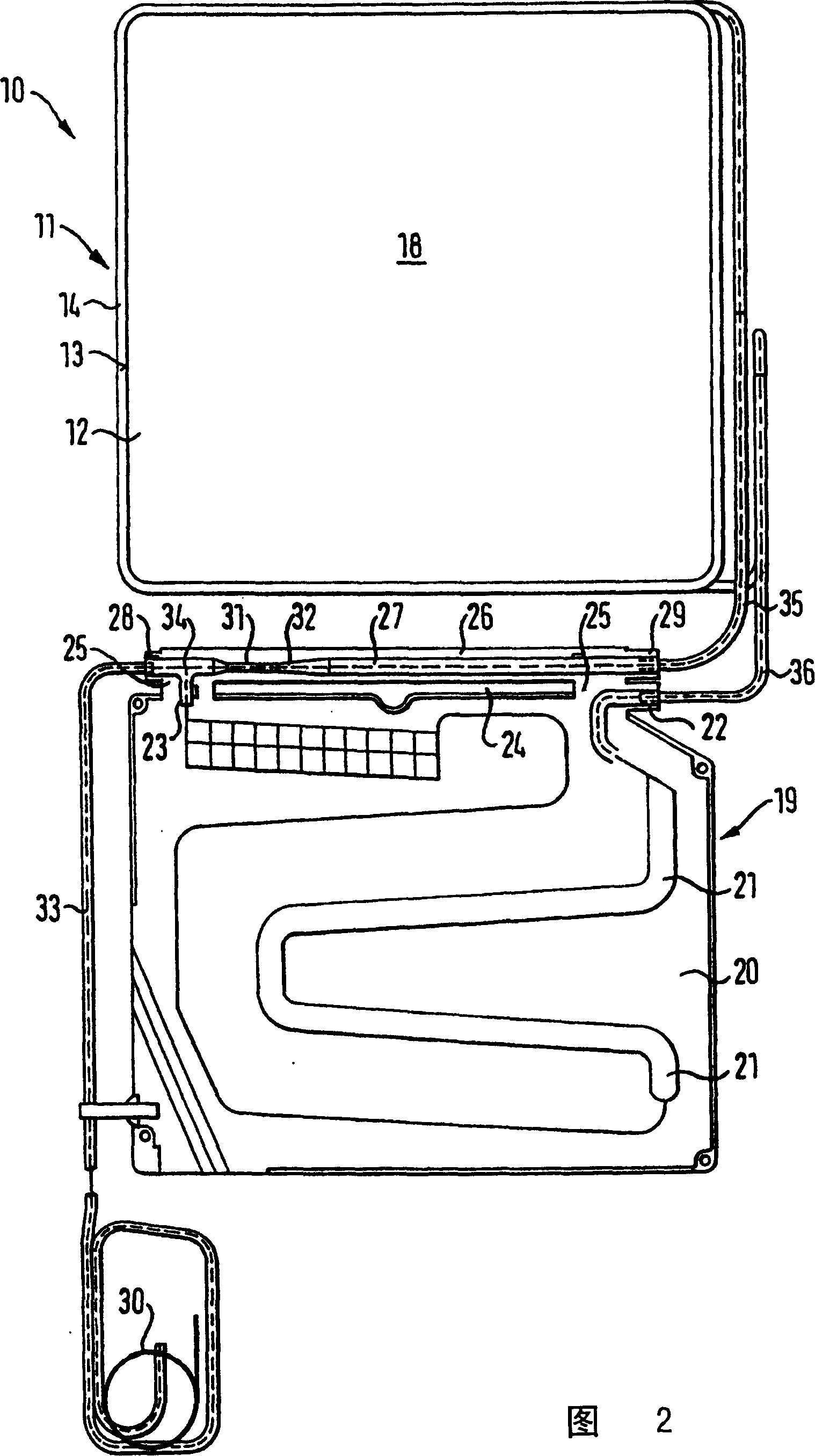

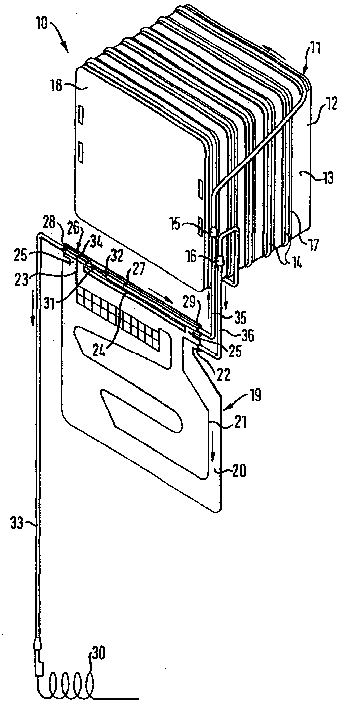

[0021] FIG. 1 shows in a simplified schematic diagram an evaporator arrangement 10 with a freezer evaporator 11 having a carrier tube 12, for example made of aluminum sheet, in the direction of the refrigerating appliance insulation. The installation surface 13 of the installation surface 13 is provided with a pipeline 14 for guiding the refrigerant, which is made of an aluminum tube and has a connector 15 or 16 at its two ends, and the aluminum tube is in thermal contact with it on the installation surface 13. In order to increase the heat transfer surface of the pipes 14 on the mounting surface 13 , the former is provided on its free surface with an aluminum-covered adhesive tape which is fastened to the mounting surface 13 of the carrier tube 12 . The carrier tube 12 is equipped on its rear side with a rear wall 18 made of aluminum sheet, which together with the carrier tube 12 and the pipes 14 wound on the carrier tube form a freezer compartment evaporator 11 known as a so-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com