Frequency-changing speed regulation driver by supplying power to both ends of windings of Three-phase asynchronous motor

A speed-regulating drive, asynchronous motor technology, applied in the direction of DC motor speed/torque control, electrical components, control systems, etc., can solve the problems of reducing the withstand voltage of switching devices, not describing the implementation scheme, adding switching devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The realization of the present invention is very simple. Common three-phase asynchronous motors provide all six terminals at both ends of the three-phase windings, so as to facilitate the change of the Δ / Y connection.

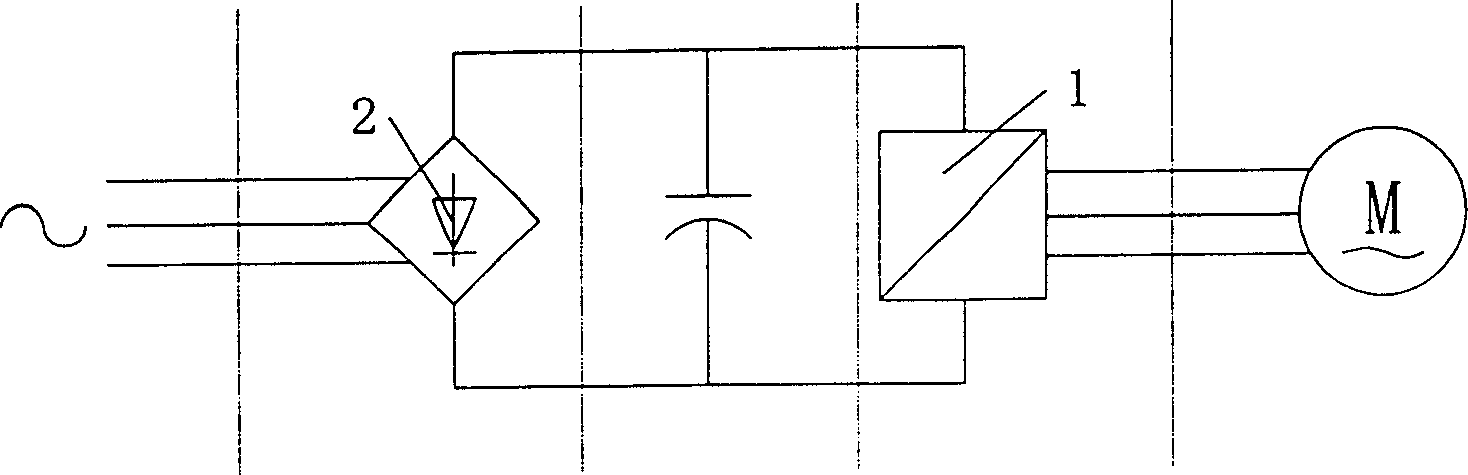

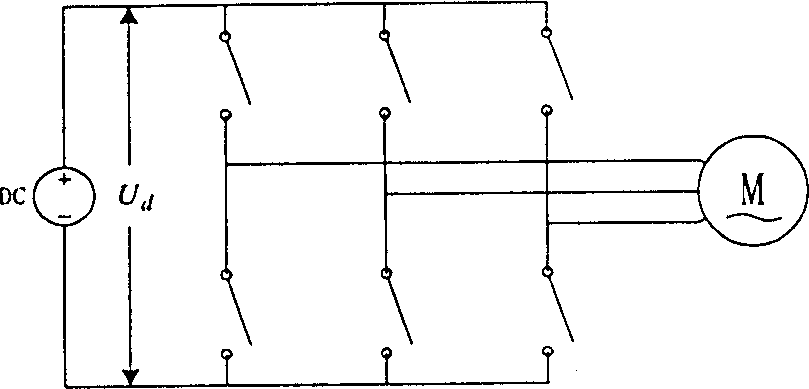

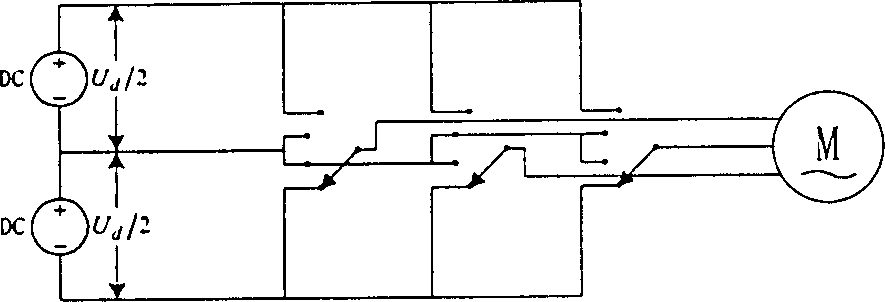

[0041] Both ends of the winding can be connected to two-level bridge arms, such as Figure 5 , can also be connected to a multi-level bridge arm, such as Image 6 , or a one-phase inverter connected to the H bridge; the inverter bridge arms connected to both ends of the winding can be symmetrical or asymmetrical, and the DC bus voltage of the inverter can be equal or unequal.

[0042] The rectifier bridge adopts a three-phase bridge rectifier circuit composed of diodes, such as Figure 7 shown.

[0043] In this topological structure, the open-loop VVVF control of the motor can be realized, and the closed-loop high-performance control such as vector control and direct torque control can also be realized. The simplest control method can directly generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com