Iron-containing mud and sintered return mine reuse method

A technology of sintering and returning ore and iron dust and sludge, which is applied in the direction of solid waste removal, etc., can solve the problems of unbalanced usage, high technical difficulty, high mud viscosity, etc., achieve considerable economic and social benefits, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

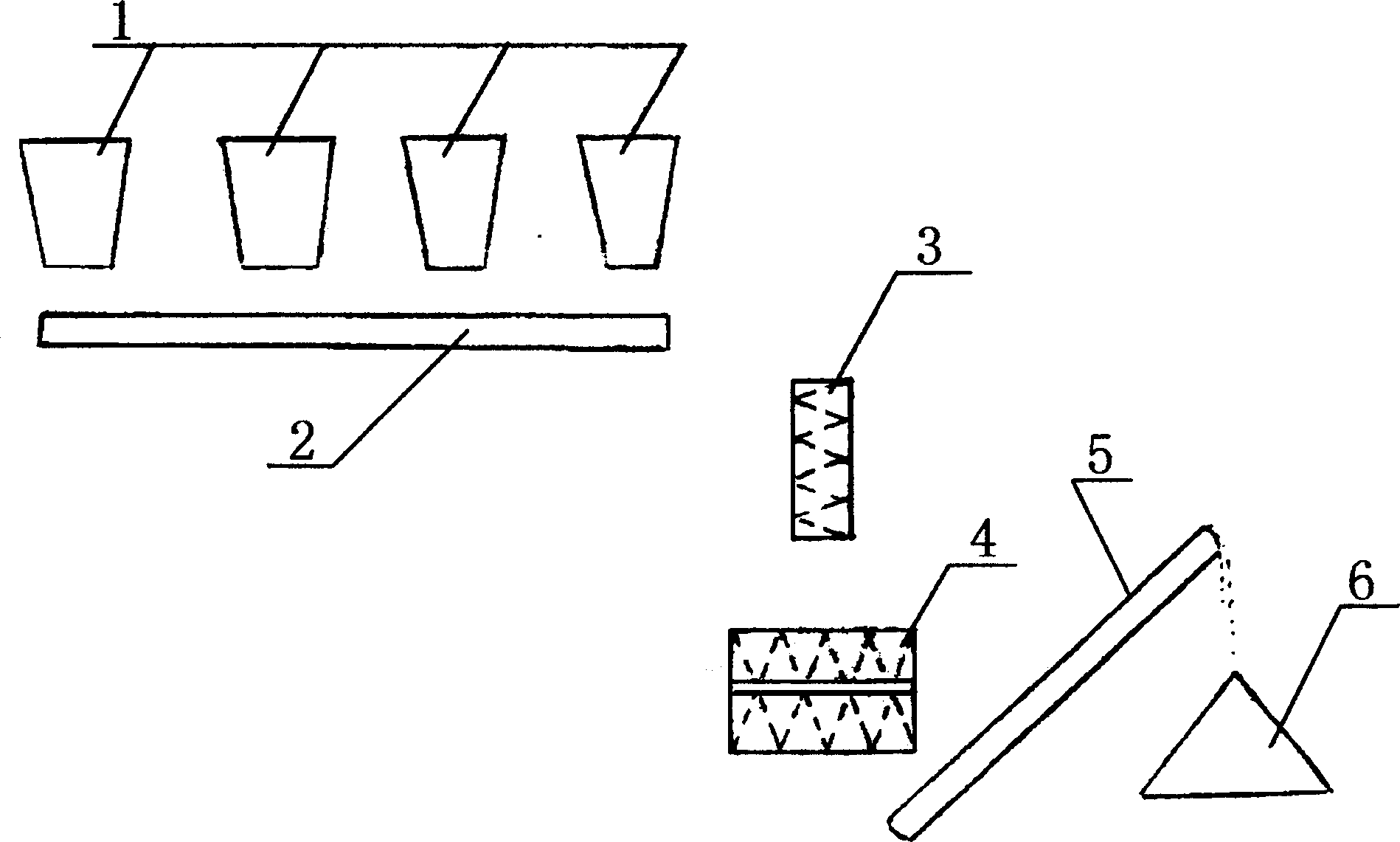

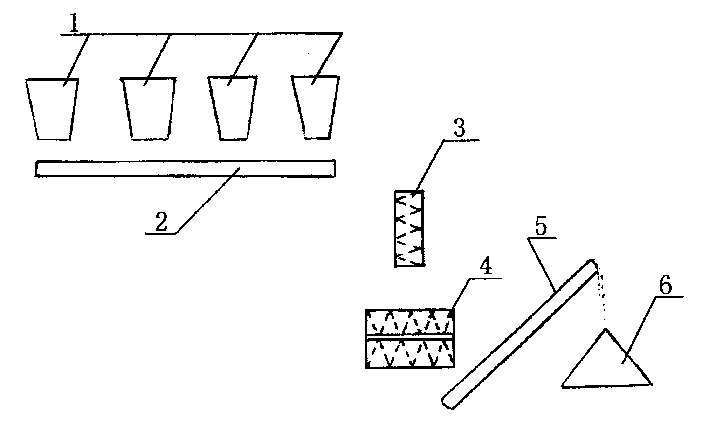

[0014] Depend on figure 1 It can be seen that the four kinds of iron-containing waste materials including converter dust sludge, sintering return ore, iron-containing waste powder and dust removal powder are respectively placed in the four material troughs 1 above the conveyor belt, and the feeding valves of the material trough 1 are controlled so that various The iron-containing waste is unloaded in proportion to the belt 2 under the hopper 1, and the belt transports the proportioned raw materials to the primary screw mixer 3 for primary mixing, and then to the secondary mixer 4 for secondary mixing. The output of the stacking belt 5 is naturally piled up, and the piled finished mixture 6 becomes the available raw material of the sintering plant, and can be transported to the sintering plant by automobile or train to participate in batching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com