Chemical battery having pressure release mechanism and producing method

A technology of decompression mechanism and battery, which is applied in the fields of containers and current collector components of electrochemical batteries, can solve problems such as shortening battery service life, and achieve the effects of reducing manufacturing cost, increasing storage life, and simplifying manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

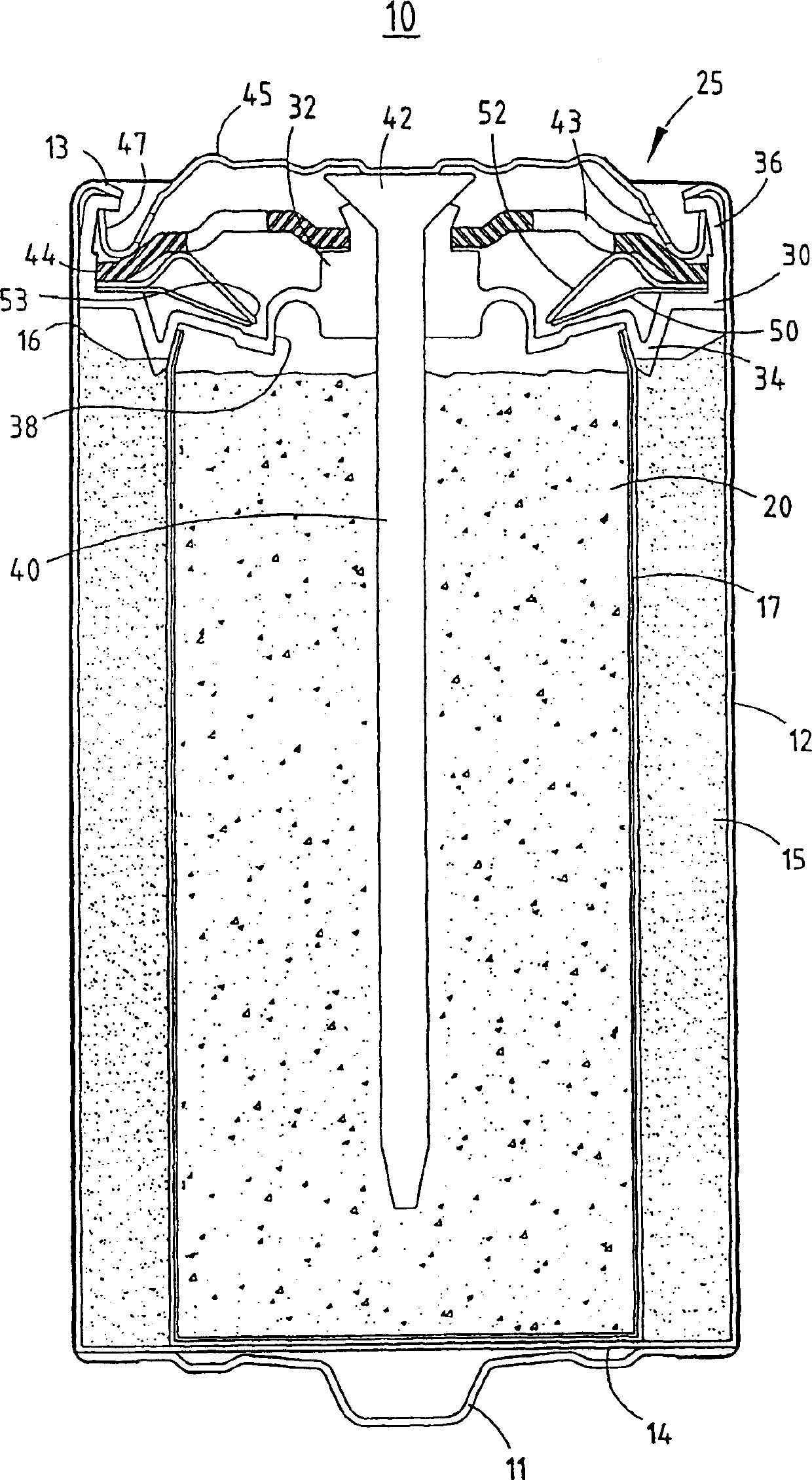

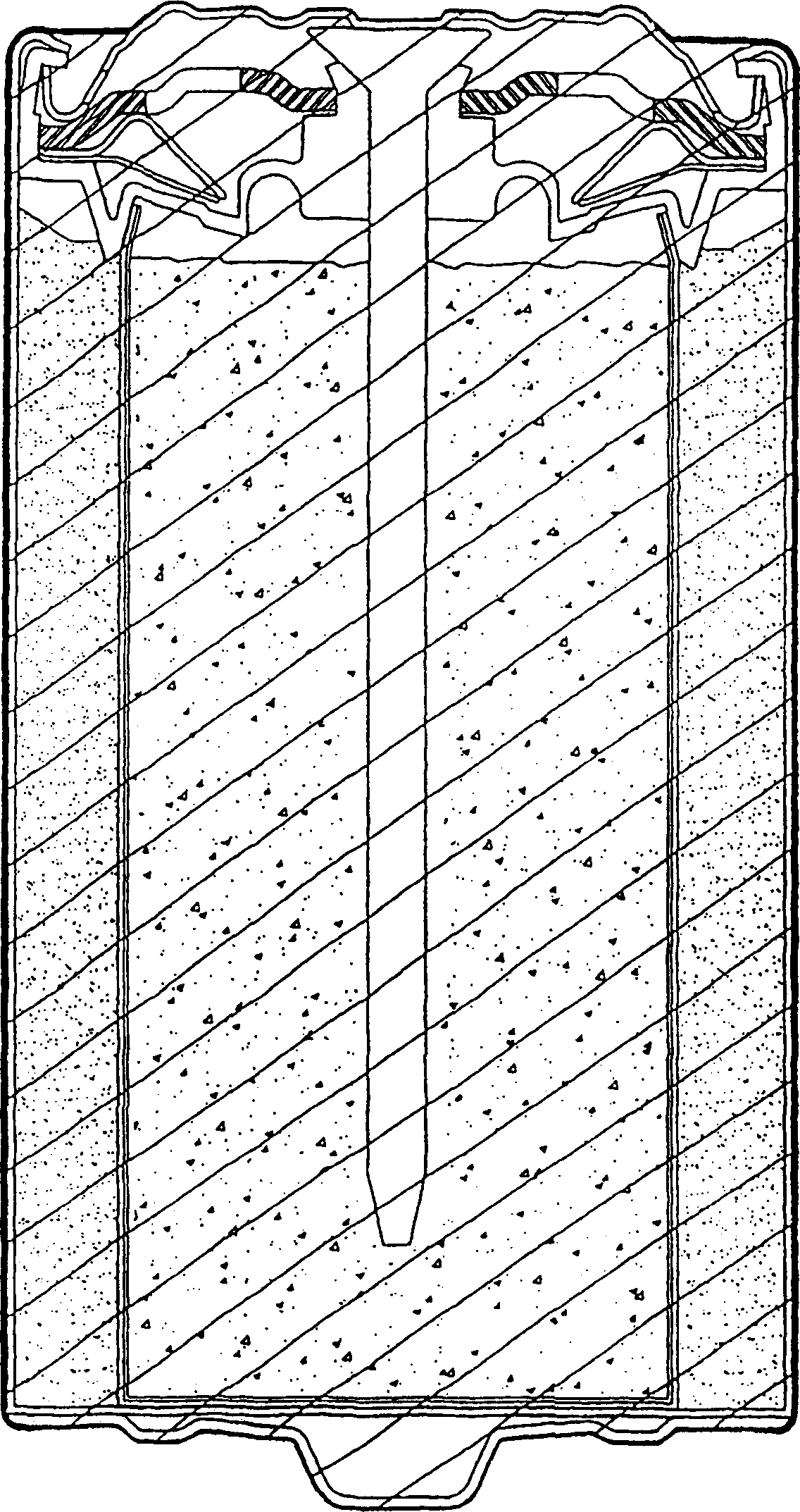

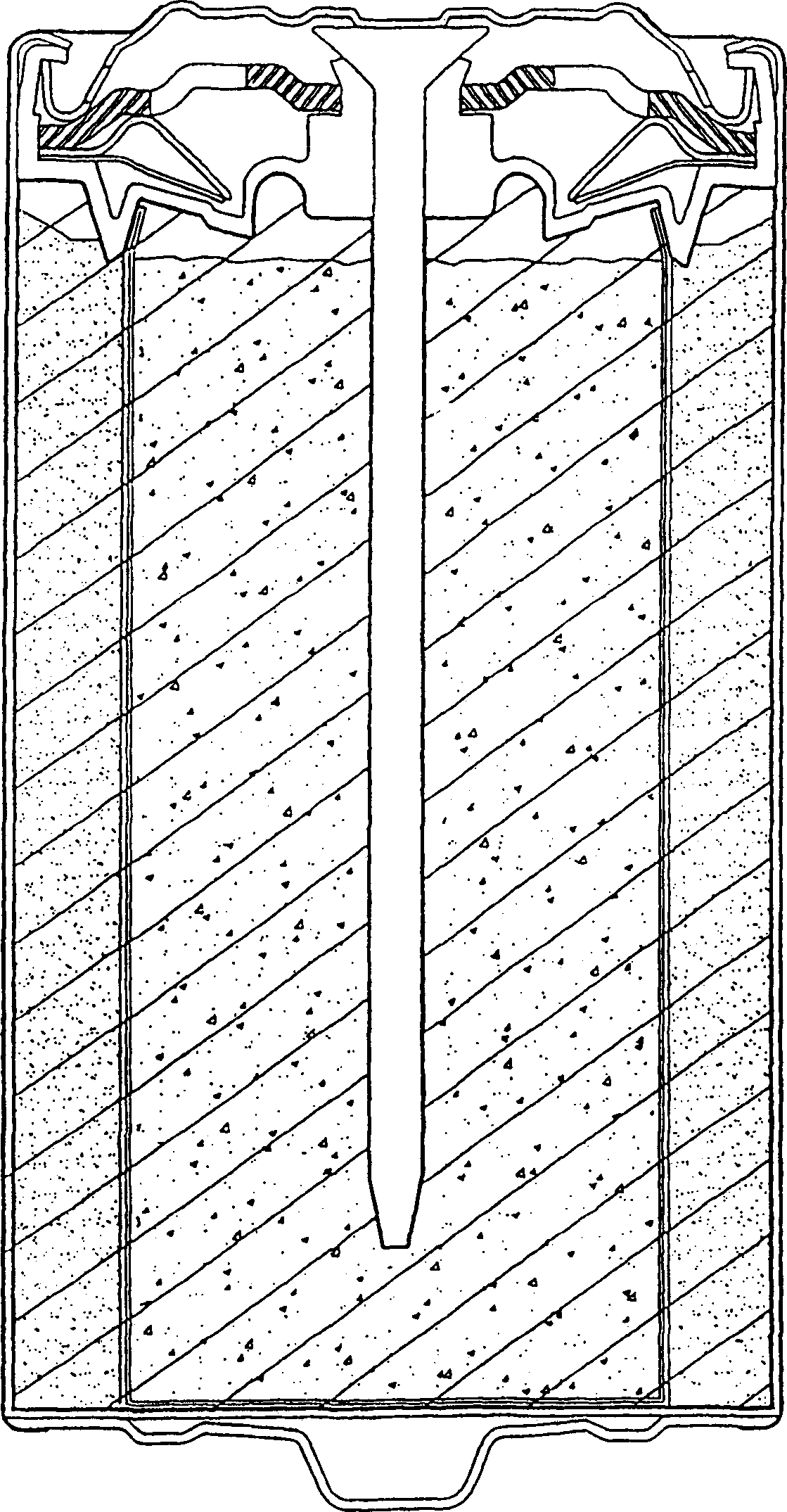

[0111] By looking at a computer-aided design (CAD) drawing, a photograph, or an actual section of a cell that has been sealed in epoxy resin and sectioned longitudinally, the total cell volume, current collector assembly volume, of each cell can be determined and the internal volume used for electrochemically active materials. The use of a CAD drawing, photograph or actual longitudinal section to observe and determine the size of the battery allows for the inclusion of any void volume that may exist within the battery. To measure the total battery volume, a section of the battery taken through its central longitudinal axis can be observed and the total volume determined by geometrical calculations. In order to determine the internal volume for the electrochemically active material, a section of the cell taken through its central longitudinal axis may be observed and the components comprising the internal volume, including the electrochemically active material confined within t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com