Roller bit with parallelly inlaid teeth

A technology of roller cone bits and inserts, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problem that the interlayer stratum cannot be drilled economically and effectively, the soft stratum cannot be drilled efficiently, and the insert cutting edge is not wide. and other problems, to achieve the effect of improving cutting conditions, low cost, and preventing mud bag phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

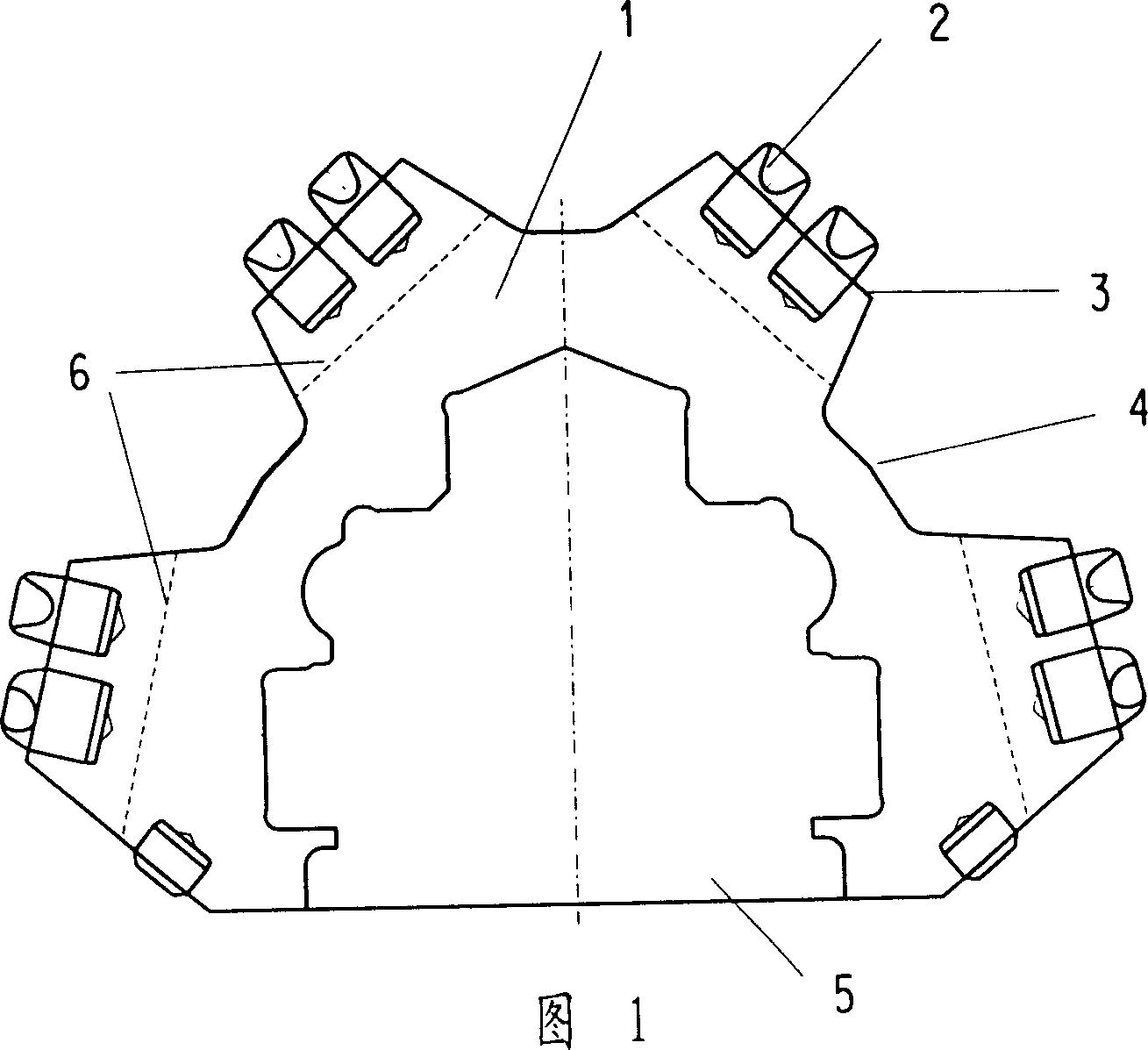

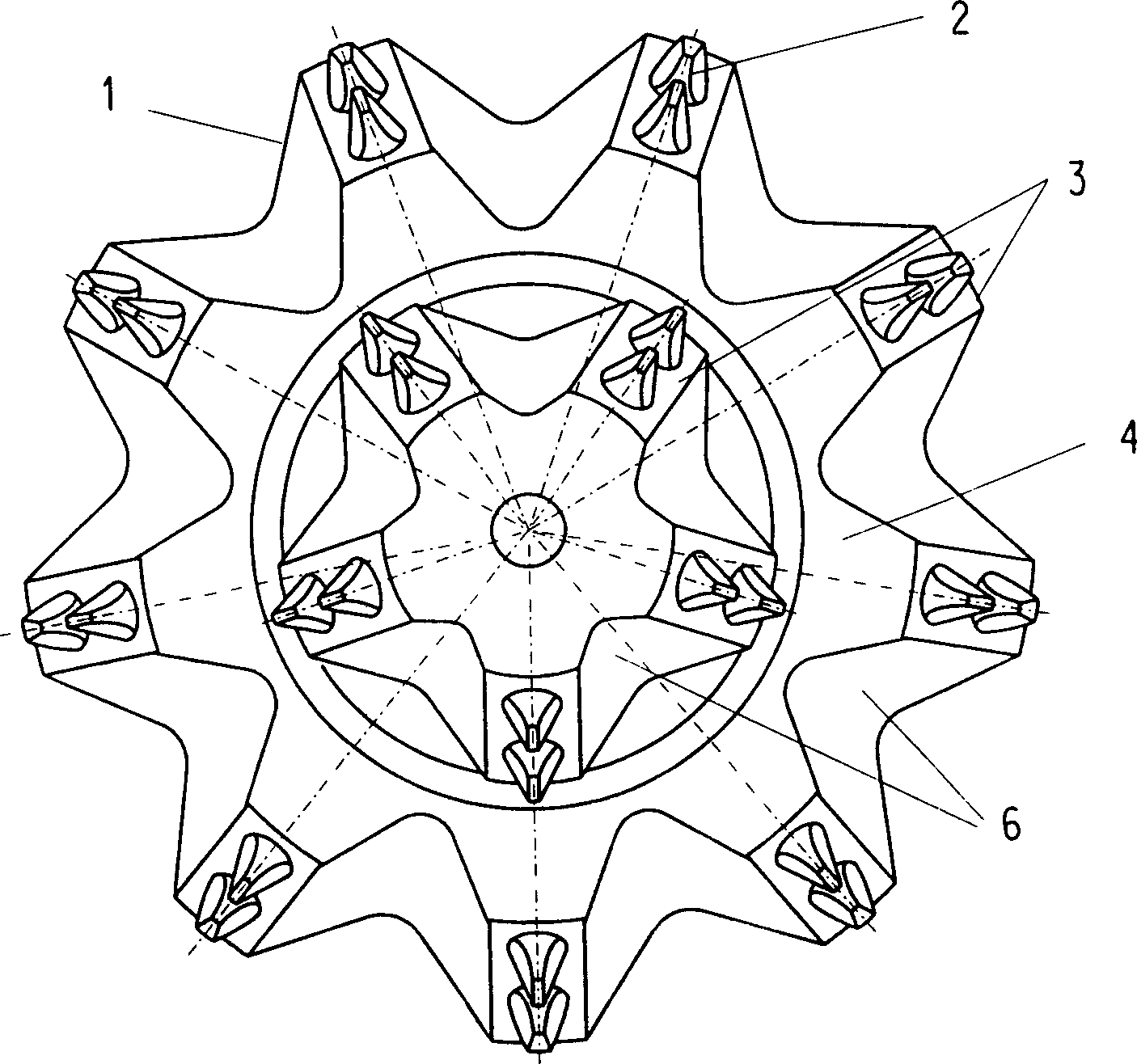

[0010] The embodiment of the present invention is further described below in conjunction with the accompanying drawings, including the palm and the cone 1, the palm is connected with the cone through the cantilever shaft at the bottom, usually 1-3 cones can be installed, the structure of the cone As shown in Figures 1 and 2, there is a coupling hole 5 inside the cone, and the shape of the cone is bevel-toothed. There are tooth grooves 6 on the ring, thus forming gear teeth. The gear teeth are in the shape of straight bevel teeth, and the tooth direction is consistent with the direction of the generatrix of the cone cone. Teeth 2, the inserts are hard alloy inserts of conventional shape, and can also be made of other high-hardness and high-strength materials. Wedge shape, the gap between the two inserts is 3mm.

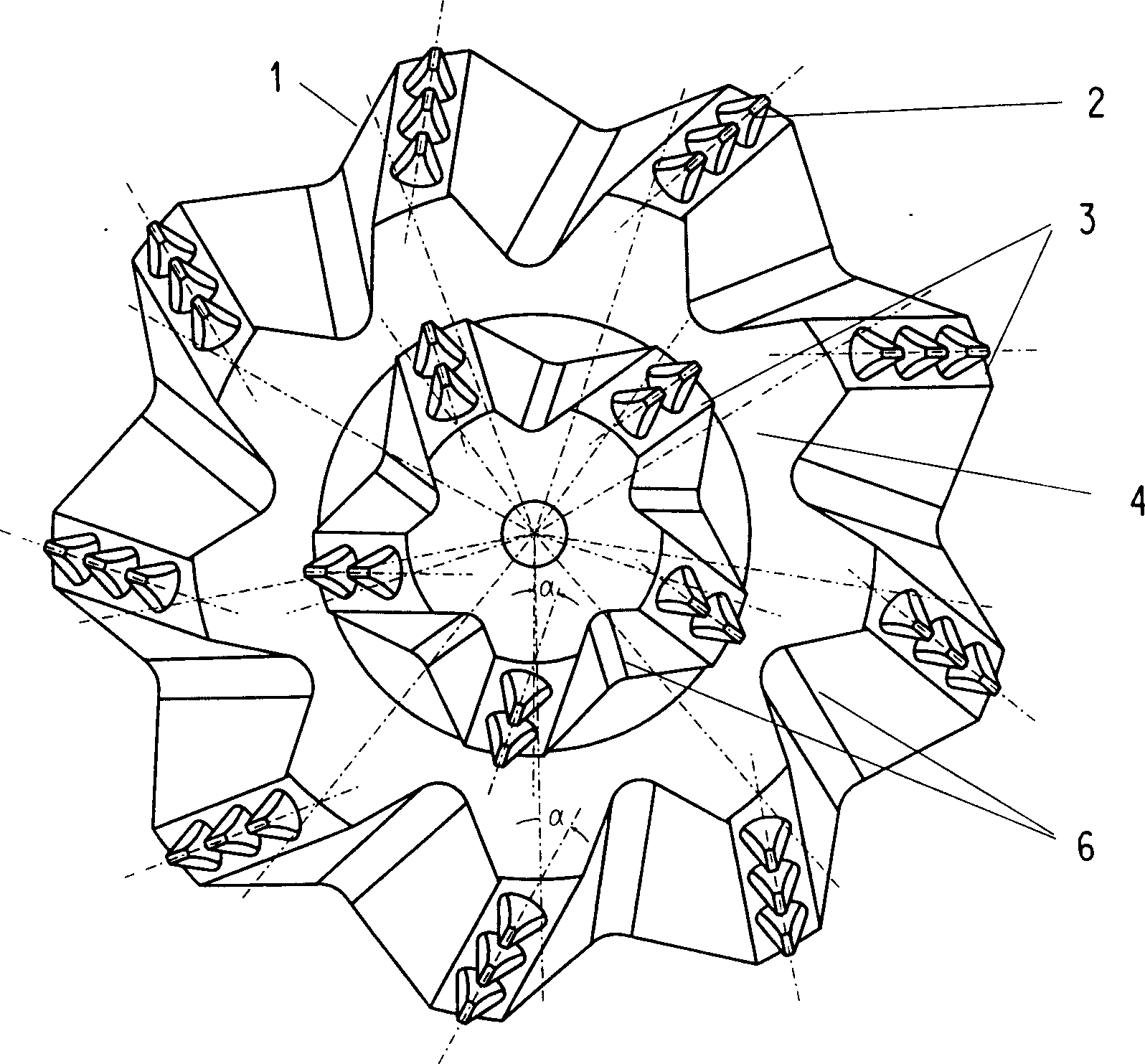

[0011] The second embodiment of the present invention is such as image 3 As shown, the main difference between it and the previous embodiment is that the teeth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com